A3 Mk2

| Removing gearbox on vehicles with 2.0 ltr. TDI engine (common rail) |

| Special tools and workshop equipment required |

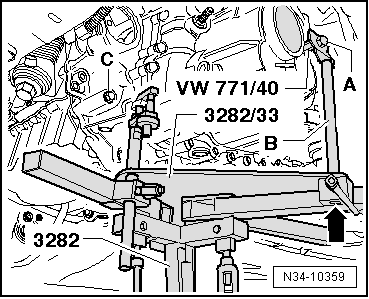

| t | Adapter -VW 771/40- |

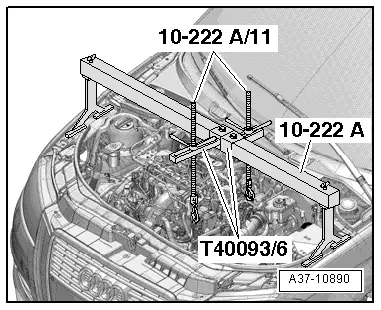

| t | Support bracket -10-222A- |

| t | Rack -10 - 222 A /1- |

| t | Hook -10 - 222 A /11- |

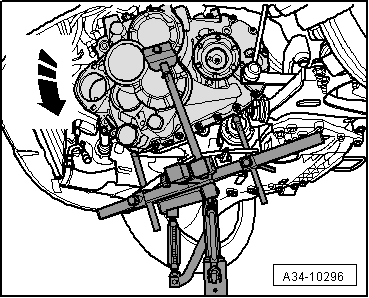

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Adapter -T40093/6- |

| t | Stepladder -VAS 5085- |

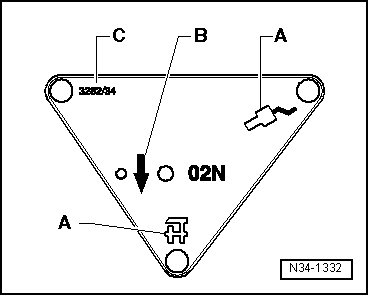

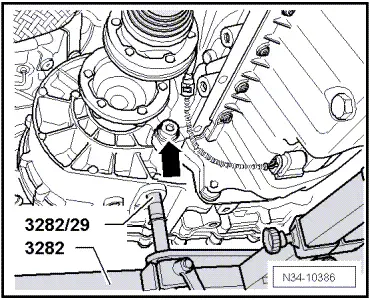

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/33- |

| t | Pin -3282/29- |

| t | Adjustment plate -3282/52- |

| t | Safety support -3282/59- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution