A3 Mk2

| Dismantling and assembling selector forks |

| Special tools and workshop equipment required |

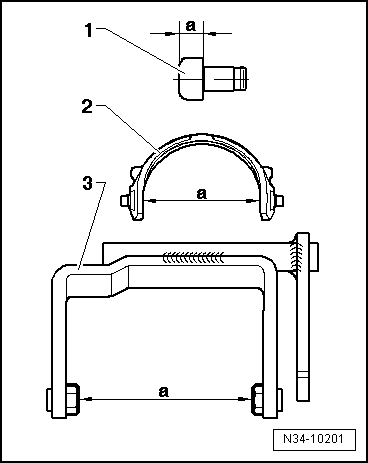

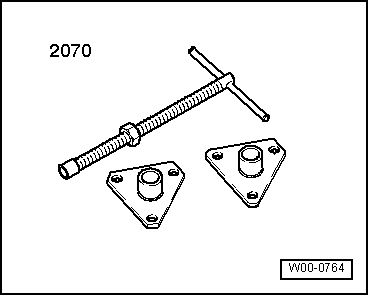

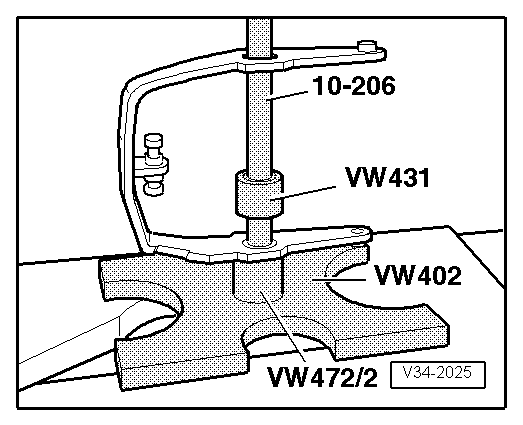

| t | Thrust plate -VW 402- |

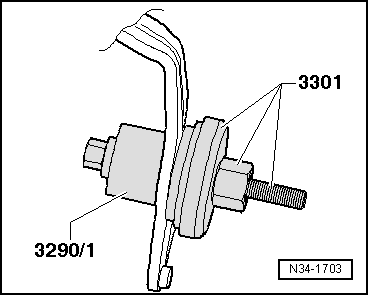

| t | Thrust piece -3290/1- |

| t | Assembly tool -3301- |

| t | Press tool -VW 431- |

| t | Spacer sleeve -VW 472/2- |

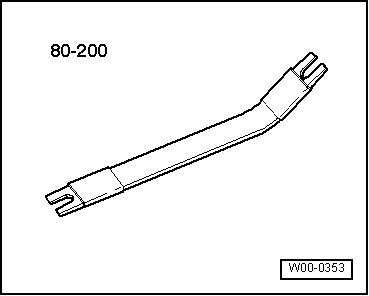

| t | Drift -10 - 206- |

|

|

|

|

|

|

Note

Note

|

|

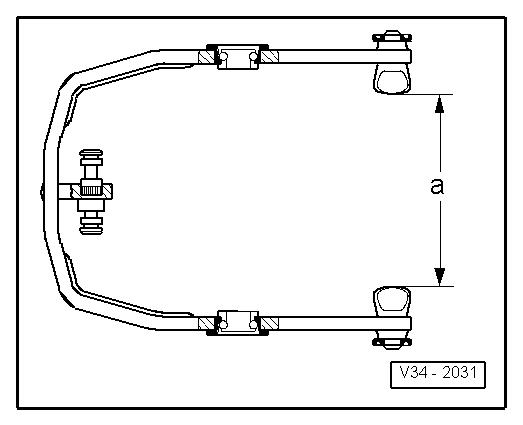

| 1 - | Selector fork cluster with selector plates |

| 2 - | 3rd/4th gear detent segment |

| q | Identification → Fig. |

| q | Detent segment should turn freely after installation. |

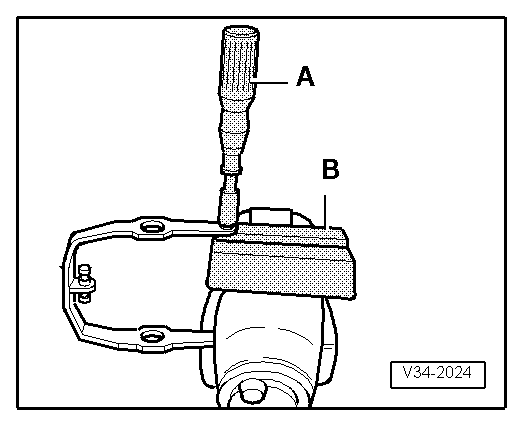

| 3 - | Angular contact ball bearing |

| q | 4x |

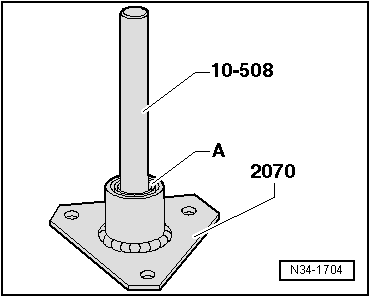

| q | Removing → Fig. |

| q | Pressing inner race into outer race → Fig. |

| q | Installing → Fig. |

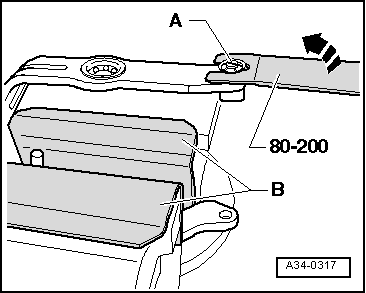

| 4 - | Lock washer |

| q | Always renew |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 5 - | 1st/2nd gear detent segment |

| q | Identification → Fig. |

| q | The segment must rotate freely after installing the lock washer |

| q | Selector fork with detent segment |

| 6 - | 5th/6th gear selector fork with detent segments |

| q | Detent segments are inseparably joined with selector fork |

| q | Identification → Fig. |

| 7 - | Pivot pin |

| q | for 5th/6th gear selector fork |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|