A3 Mk2

| Exploded view - assembly mountings |

| 1 - | Bolt |

| q | Engine mounting to engine |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 2 - | Bolt |

| q | Engine mounting to engine |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 3 - | Bolt |

| q | Engine mounting to body |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 4 - | Bracket |

| q | For activated charcoal filter |

| 5 - | Bolt |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 6 - | Nut |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 7 - | Engine mounting |

| q | Checking adjustment → Engine, mechanics; Rep. gr.10 |

| q | Adjusting → Engine, mechanics; Rep. gr.10 |

| q | Removing and installing → Engine, mechanics; Rep. gr.10 |

| 8 - | Connecting bracket |

| 9 - | Bolt |

| q | Connecting bracket to body |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 10 - | Bolt |

| q | Connecting bracket to engine mounting |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 11 - | Bolt |

| q | Engine mounting to body |

| q | Tightening torque → Engine, mechanics; Rep. gr.10 |

| 12 - | Pendulum support |

| q | Removing and installing → Chapter |

| 13 - | Bolt |

| q | Pendulum support to subframe |

| q | 100 Nm +90° |

| q | Do not tighten until pendulum support has been bolted to gearbox |

| q | Always renew |

| 14 - | Bolt |

| q | Pendulum support to gearbox |

| q | 60 Nm +90° |

| q | Always renew |

| 15 - | Bolt |

| q | Pendulum support to gearbox |

| q | 60 Nm +90° |

| q | Always renew |

| 16 - | Bolt |

| q | Gearbox mounting to gearbox |

| q | 60 Nm +90° |

| q | Always renew |

| 17 - | Bolt |

| q | Gearbox mounting to body |

| q | 40 Nm +90° |

| q | Always renew |

| 18 - | Gearbox mounting |

| q | Checking adjustment → Engine, mechanics; Rep. gr.10 |

| q | Adjusting → Engine, mechanics; Rep. gr.10 |

| q | Removing and installing → Chapter |

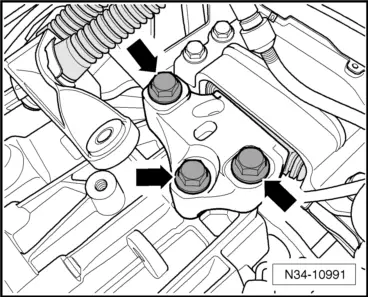

| q | Tightening torque and sequence → Fig. |

|

|

Caution

Caution