| t

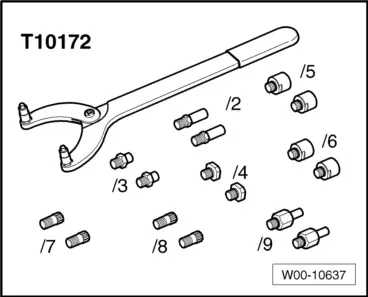

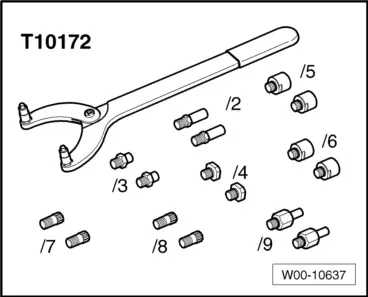

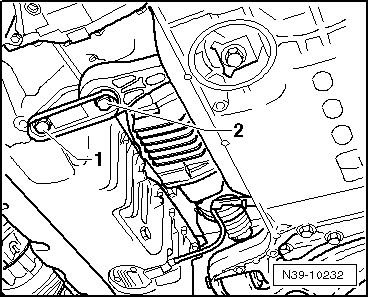

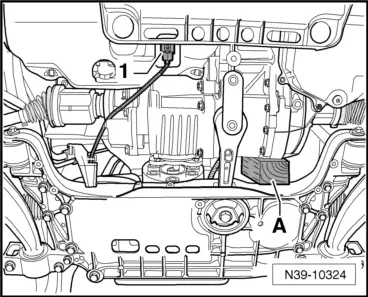

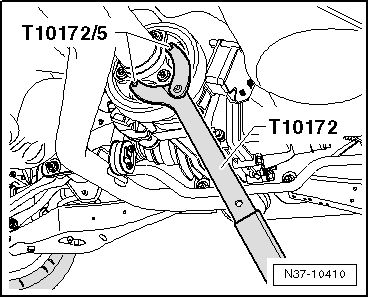

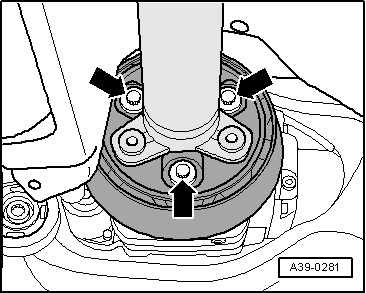

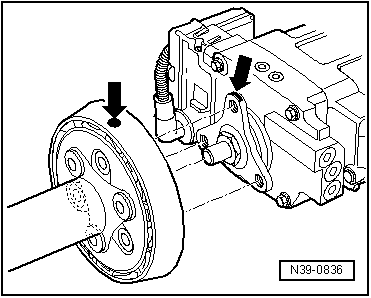

| Counterhold tool -T10172- with adapters -T10172/5- |

Note | t

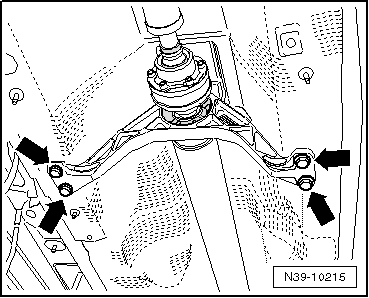

| Repairs on the propshaft should preferably be carried out on a two-pillar hoist. |

| t

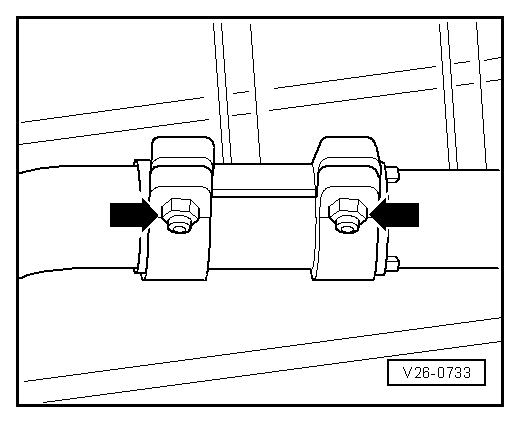

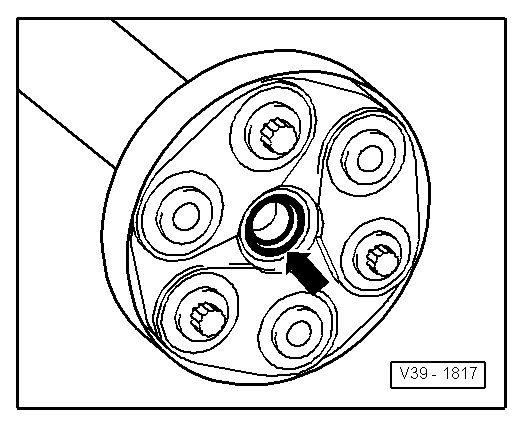

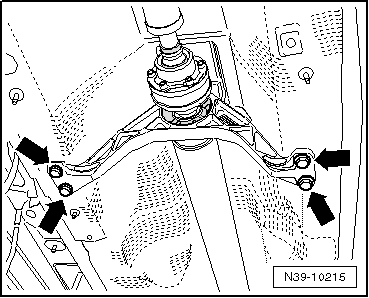

| Before removing, mark the positions of all parts in relation to each other. Reinstall in the same position to avoid excessive imbalance, resulting in bearing damage and rumbling noise. |

| t

| Do not bend propshaft; only store and transport fully extended. |

| t

| Always support the propshaft during removal; it must not be suspended from one of the joints. |

| t

| Always keep the propshaft horizontal while pulling it off or fitting it on the joint flange. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution