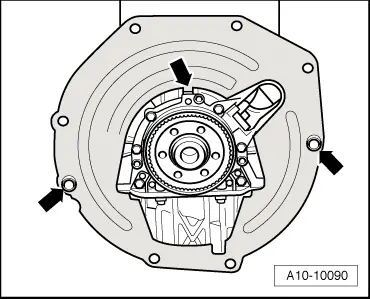

| Flywheel/drive plate and sealing flange - exploded view of components |

Caution | t

| The crankshaft must not be removed. Even loosening the main bearing cap bolts will cause deformation of the cylinder block bearing pedestals. This will result in reduced bearing clearance. Even if bearing shells are not renewed, a change in bearing clearance can cause bearing damage. |

| t

| If the bearing cap bolts are loosened, the cylinder block must be renewed together with the crankshaft. |

| t

| Crankshaft bearing clearance cannot be measured using workshop equipment. |

|

|

|

|

Caution

Caution