A3 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

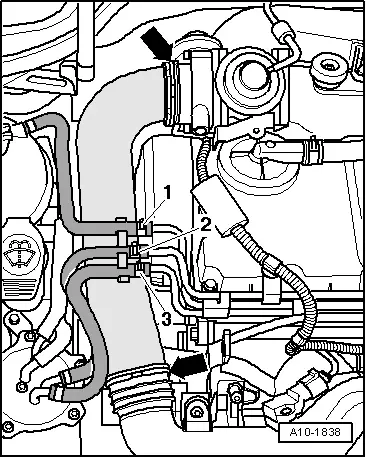

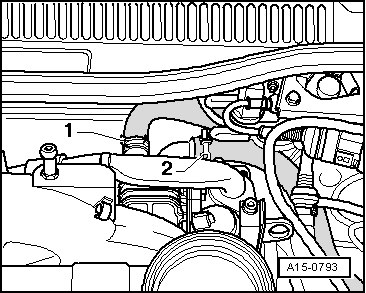

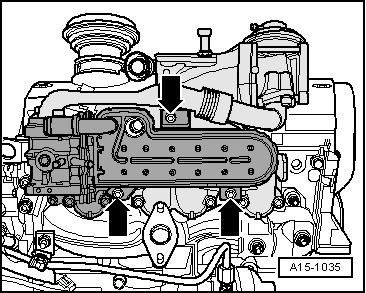

| Component | Nm |

| Exhaust gas recirculation cooler to intake manifold | 10 |

| Bracket to intake manifold | 10 |

| Connecting pipe for exhaust gas recirculation to change-over flap | 22 |

| Intake manifold flap motor -V157- to intake manifold | 10 |

| Engine lifting eye to cylinder head | 22 |