| –

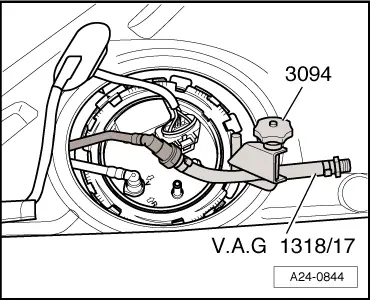

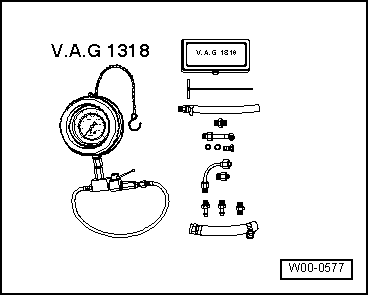

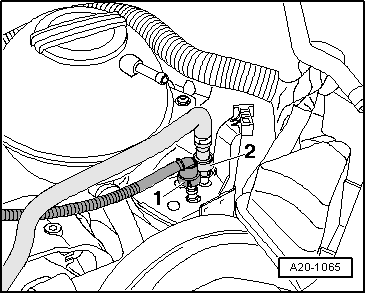

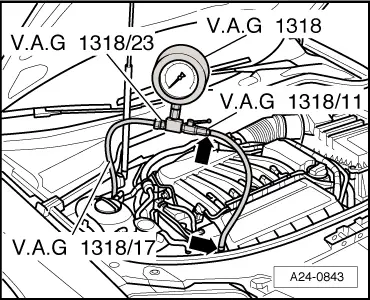

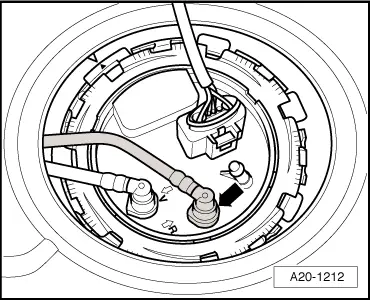

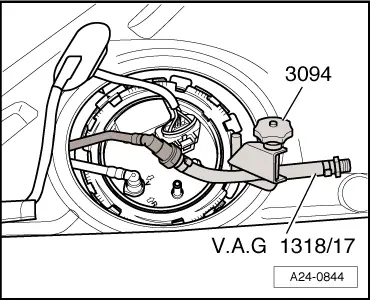

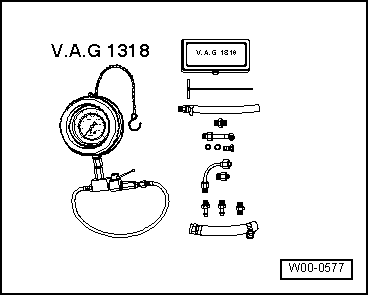

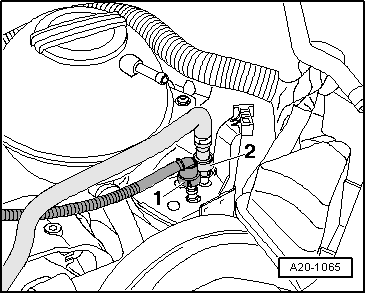

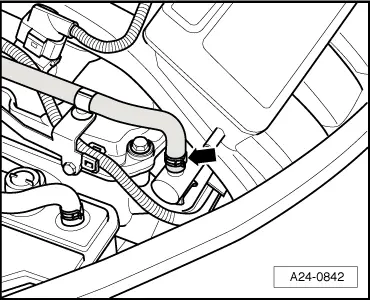

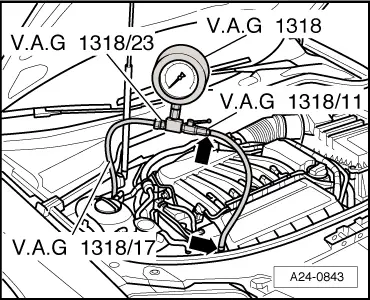

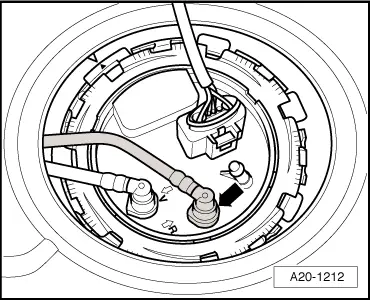

| Connect adapter hose -1318/17-1- to fuel return pipe. |

| –

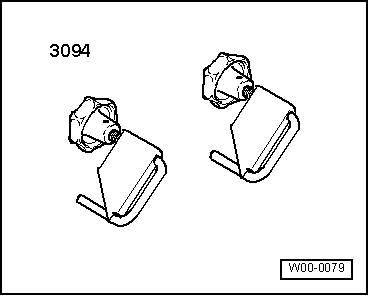

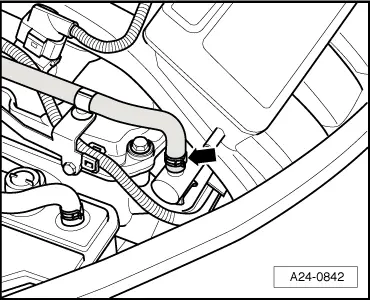

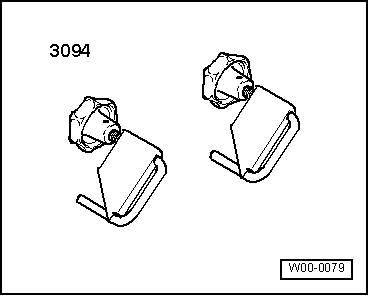

| Clamp off adapter hose using hose clamp -3094-. |

Note | Do not attach hose clamp -3094- directly to fuel pipe - Danger of damage. |

| –

| Cover the return pipe connection with a cloth. |

| –

| Start the engine and briefly run at idling speed. |

| –

| Allow pressure to build up, then switch off ignition. |

| –

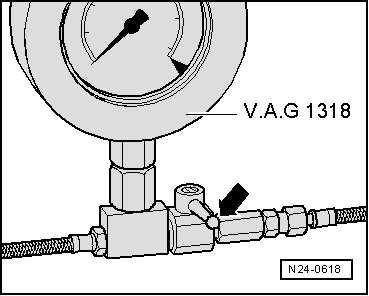

| Observe pressure drop on pressure gauge. |

| If pressure does not drop, non-return valve of fuel pump is defective. |

| If the pressure drops again: |

| –

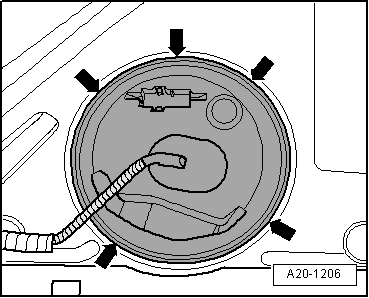

| Renew fuel filter with integral fuel pressure regulator → Rep. Gr.20. |

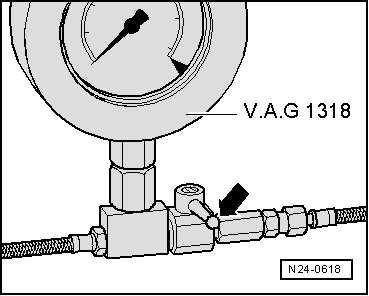

Note | Before removing the pressure tester, release the fuel pressure by opening the cut-off valve. Hold a container under the connection. |

| –

| Assembly is carried out in the reverse order; note the following: |

| –

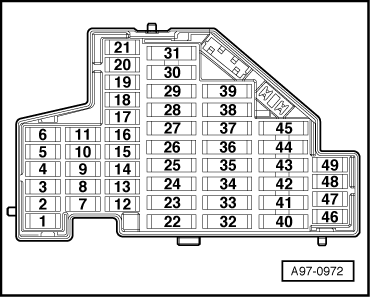

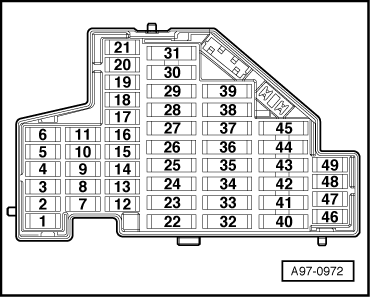

| Re-insert fuse SC27 in fuse holder in dash panel (left-side). |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note