| –

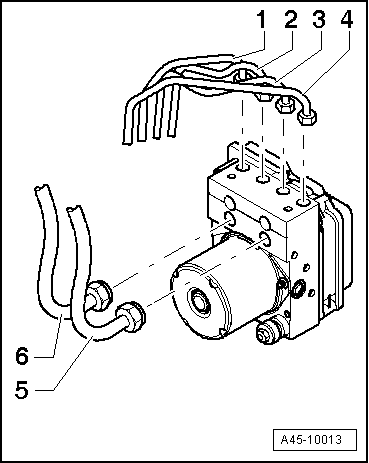

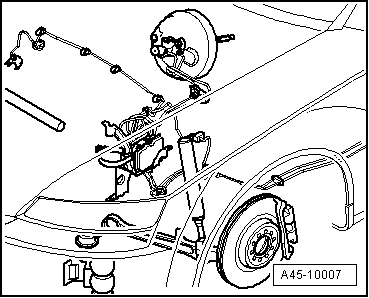

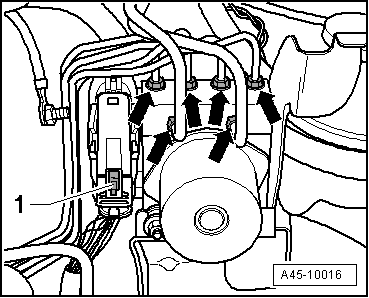

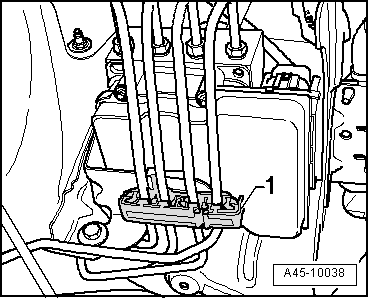

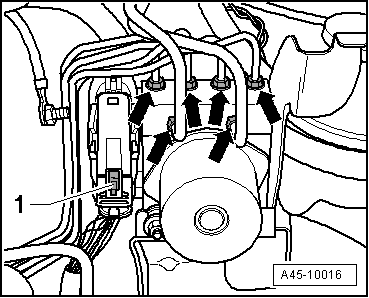

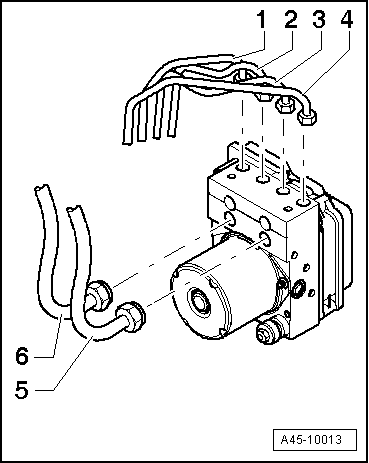

| Connect pipes as previously marked: |

| 1 - | To front right brake caliper |

| 2 - | To rear left brake caliper |

| 3 - | To rear right brake caliper |

| 4 - | To front left brake caliper |

| 5 - | To primary piston circuit |

| 6 - | To secondary piston circuit |

| –

| Fit connector on hydraulic pump. |

| –

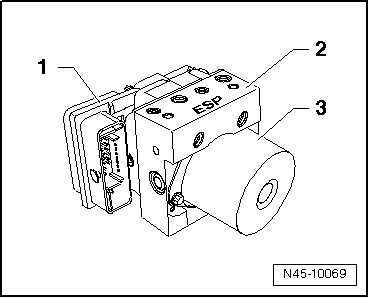

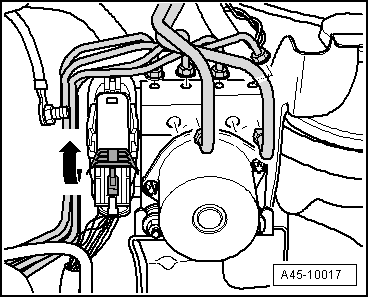

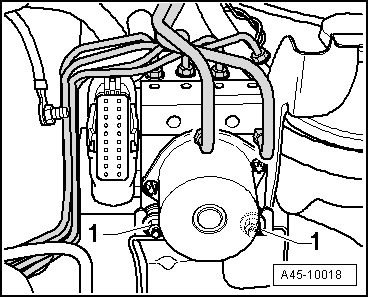

| Clip ABS unit onto bracket. |

Note | Do not tighten bolts completely. This will make it easier to attach the individual brake lines to the hydraulic unit. |

| –

| After tightening brake lines, tighten hydraulic unit. |

| –

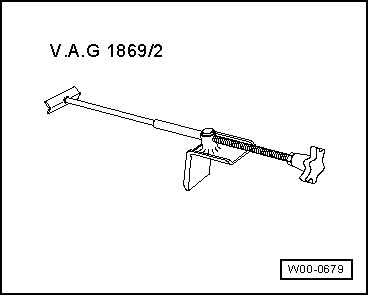

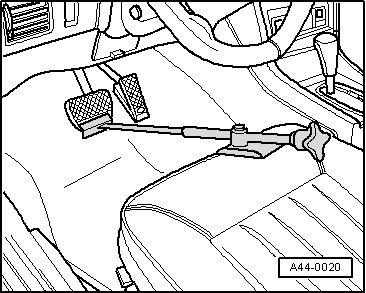

| Remove brake pedal actuator -V.A.G 1869/2-. |

| –

| When renewing the control unit, select the function “Replacing” for the relevant control unit in the “Guided Fault Finding”. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051A-. |

Note | Final control diagnosis can be used to establish whether line connections have been interchanged → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING