A4 Cabriolet Mk2

| Servicing conventional clutch |

Note

Note| The gearbox has to be removed before working on the clutch → Chapter „Removing gearbox - vehicles with 4-cyl. petrol engine“. |

| 1 - | Dual-mass flywheel |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| q | Removing and installing → Rep. Gr.13 |

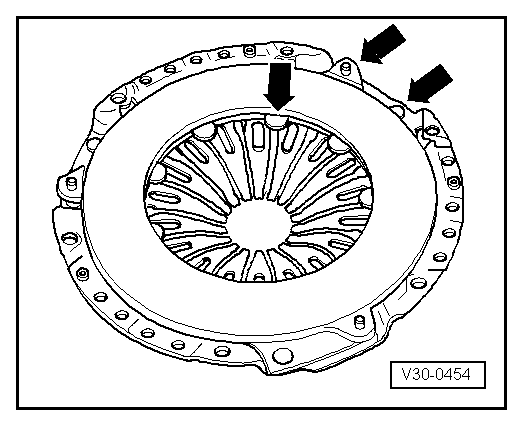

| q | Do not use a pneumatic wrench or impact wrench to remove bolts → Fig. |

| 2 - | Bolt |

| q | Tightening torque for bolt length 22.5 mm: 60 Nm + 90° further |

| q | Tightening torque for bolt length 43 mm: 60 Nm + 180° further |

| q | Renewing → Rep. Gr.13 |

| 3 - | Clutch plate |

| q | Install with damper assembly (coil springs) or the word “Getriebeseite” (gearbox side) towards pressure plate and gearbox |

| q | Centralising → Anchor |

| q | Clutch plate diameter → Chapter „Code letters, allocation, transmission ratios, capacities“ |

| 4 - | Pressure plate |

| q | Removing and installing → Chapter |

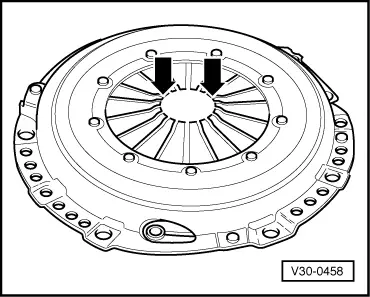

| q | Checking ends of diaphragm spring → Fig. |

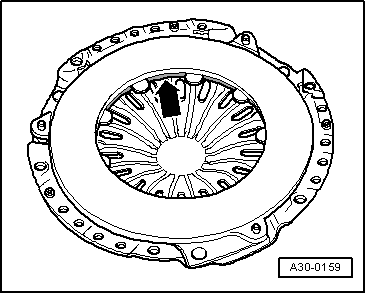

| q | Check spring connection and rivets → Fig. |

| q | Checking wire ring → Fig. |

| 5 - | Bolt, 22 Nm |

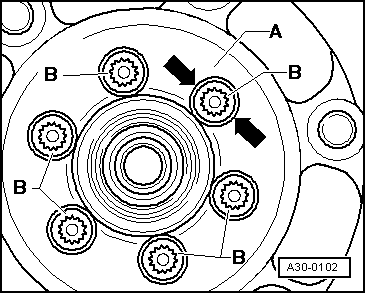

| Observe tightening sequence → Anchor |

| 6 - | Needle bearing |

| q | Removing and installing → Rep. Gr.13 |

Note

Note

|

|

|

|

Note

Note

|

|