| –

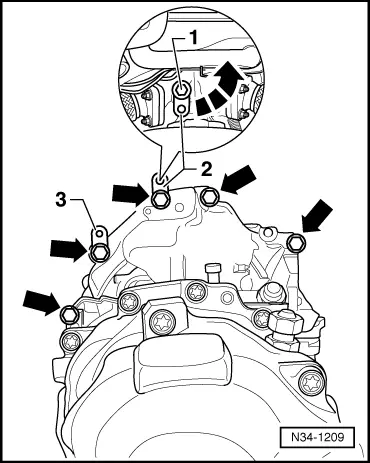

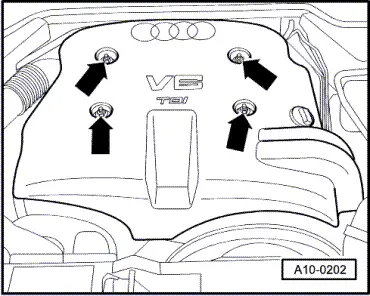

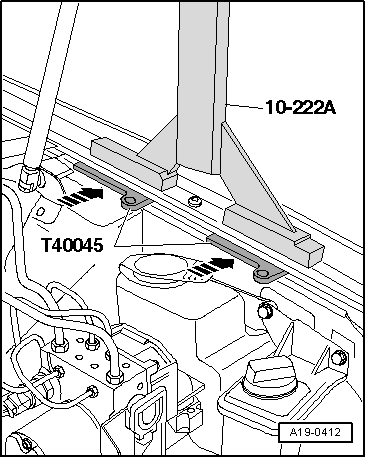

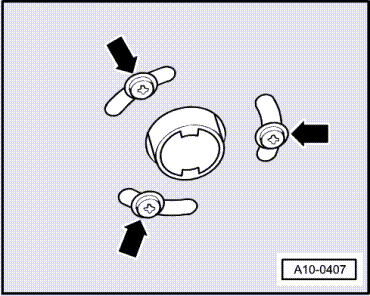

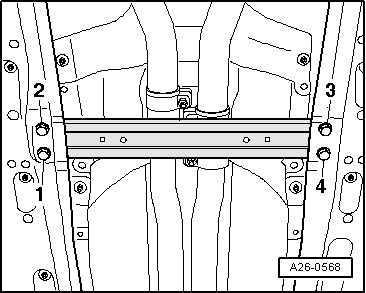

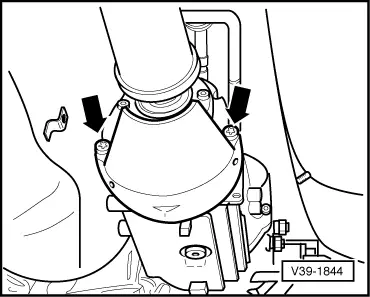

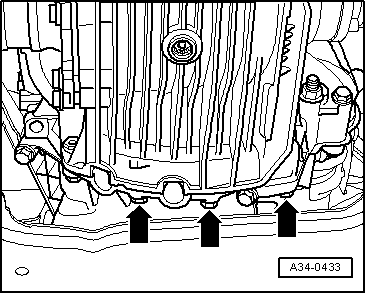

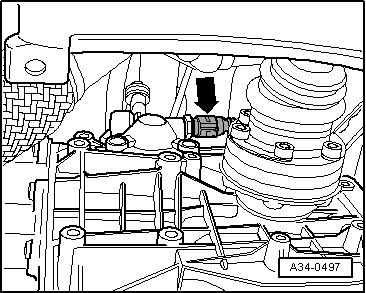

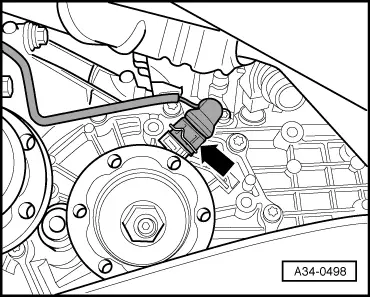

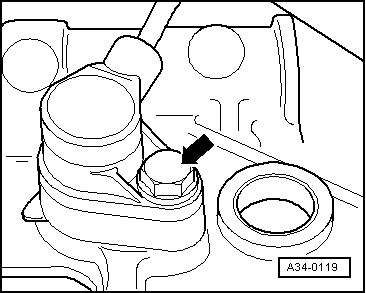

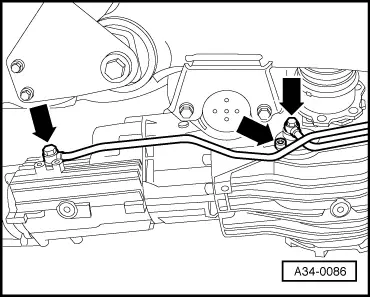

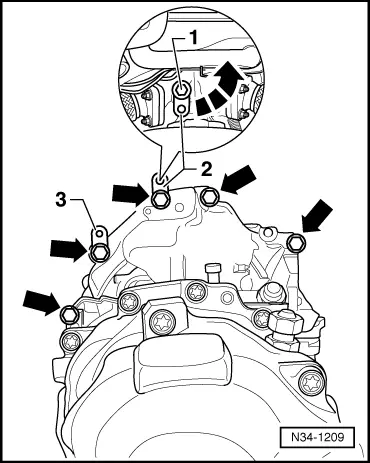

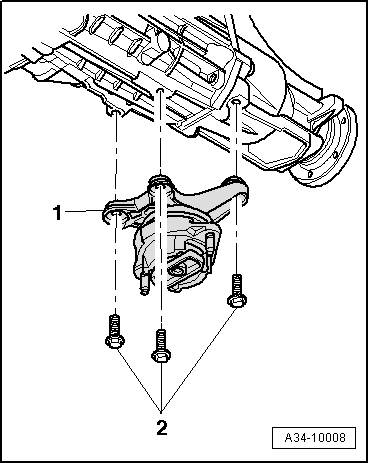

| Unscrew top engine/gearbox securing bolts -arrows-. |

| –

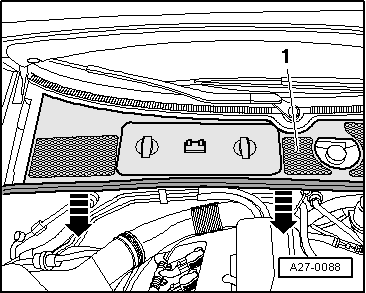

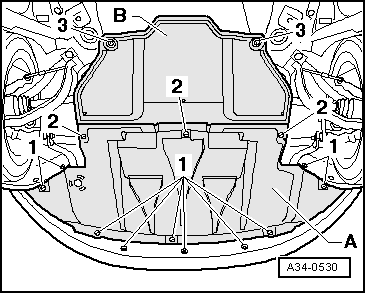

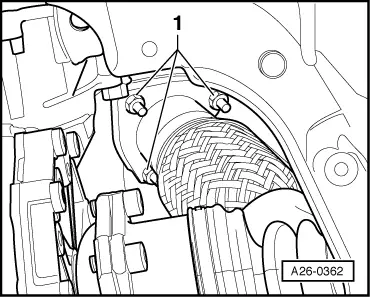

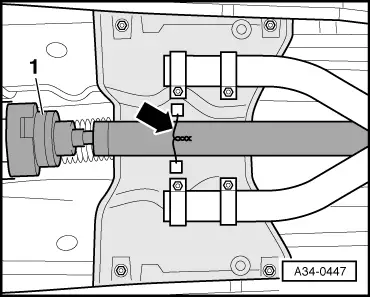

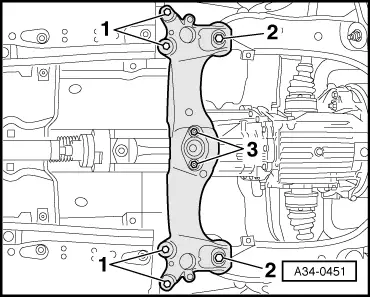

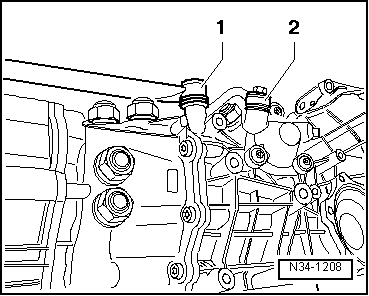

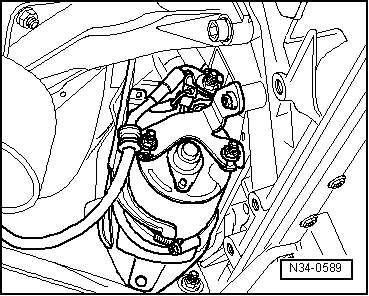

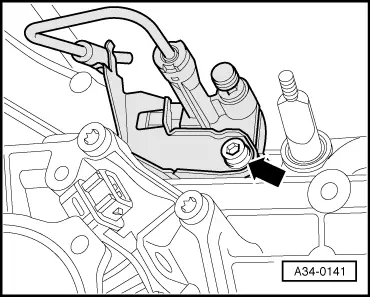

| Slacken bolt -1- (at rear of turbocharger) a few turns and pivot brace -2- to one side in direction of -arrow-. Then tighten bolt -1- again lightly. |

| –

| If fitted, move bracket -3- with wiring clear to the side and secure with wire. |

| –

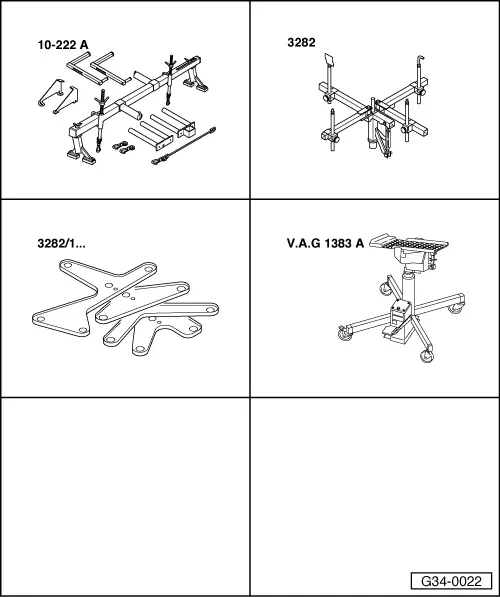

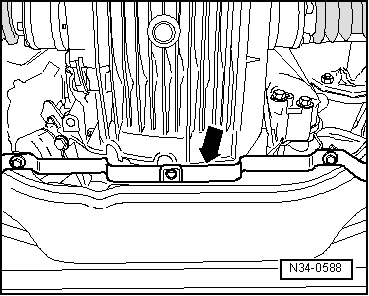

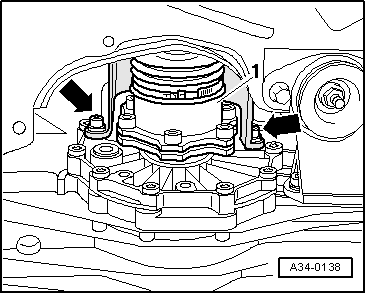

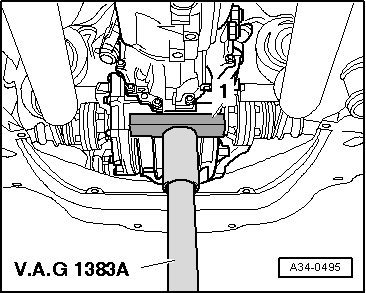

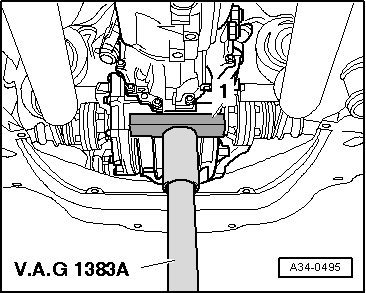

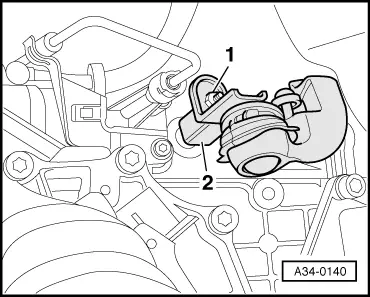

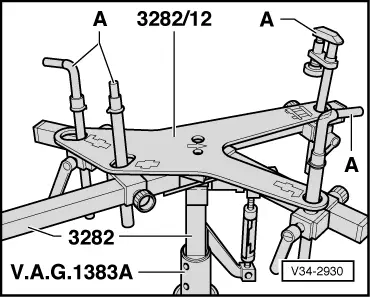

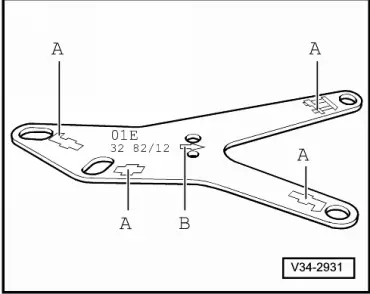

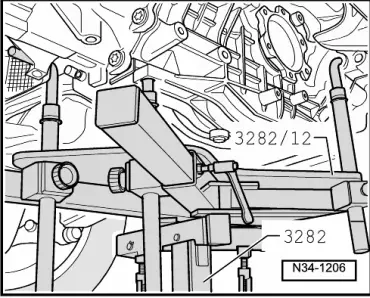

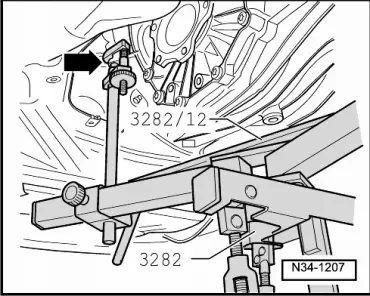

| Press gearbox off dowel sleeves and lower carefully with engine and gearbox jack -V.A.G 1383 A- just far enough to gain access to the clutch slave cylinder. |

Note | When lowering gearbox, ensure hydraulic pipe/hose to slave cylinder is not damaged. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution