| Installing gearbox - vehicles with 3.0 ltr. TDI engine |

| Installation is carried out in reverse sequence; note the following: |

| –

| Use thread tap to remove any remaining locking fluid from all threaded holes which will accommodate self-locking bolts. |

| –

| Always renew self-locking bolts and nuts. |

| –

| Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease for clutch plate splines -G 000 100- to the splines. Do not grease guide sleeve. |

| l

| It should be possible to push the clutch plate back and forth slightly on the input shaft. |

| –

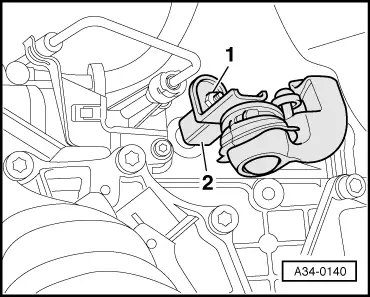

| Check clutch release bearing for wear and make sure the plastic ring is securely attached; renew if necessary → Chapter. |

| –

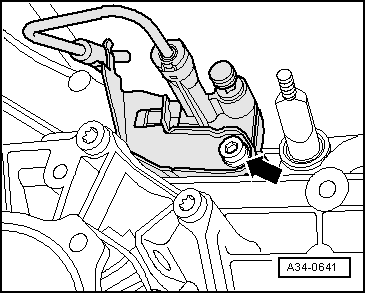

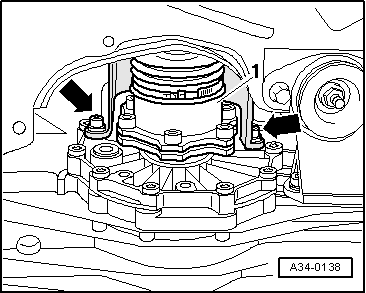

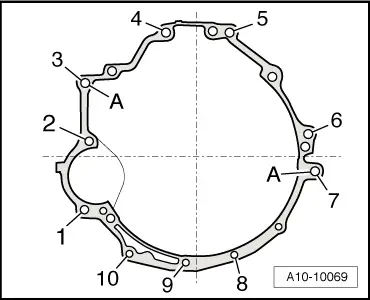

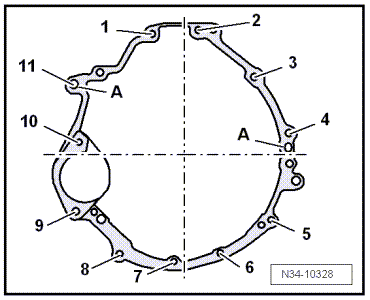

| Check that dowel sleeves for centralising engine/gearbox are in the cylinder block, install if necessary. |

| –

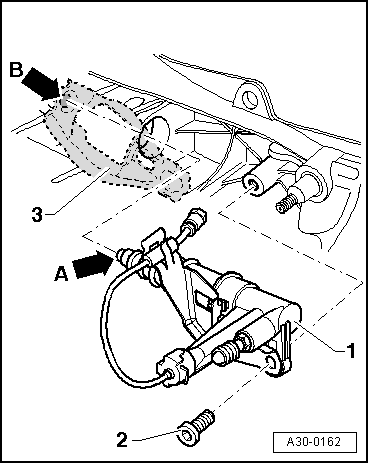

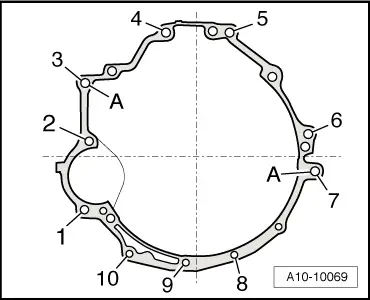

| If fitted, place intermediate plate on dowel sleeves at engine flange. |

| –

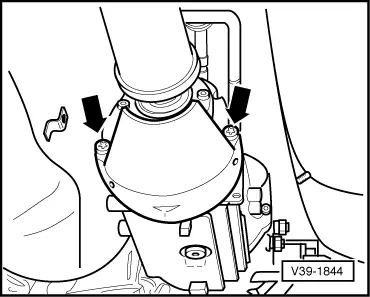

| Before installing gearbox, tie electrical wiring and brackets off to one side so that they are not trapped between the engine and the gearbox. |

| –

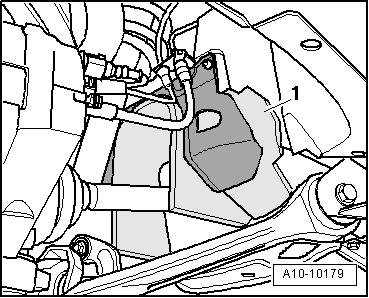

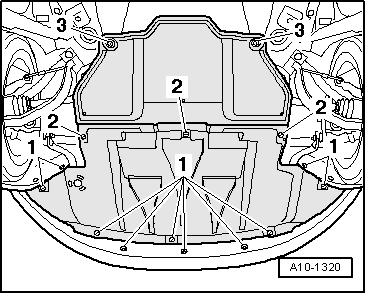

| Place gearbox on gearbox jack. |

|

|

|

Note

Note

Note

Note

Caution

Caution