A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

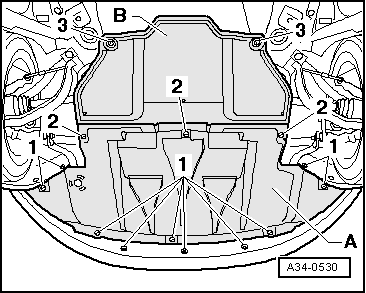

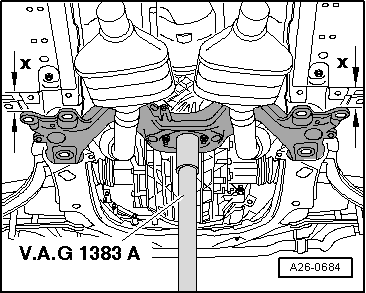

| Component | Nm |

| Heat shield for drive shaft to gearbox | 23 |

| Heat shield for propshaft to gearbox cover | 25 |