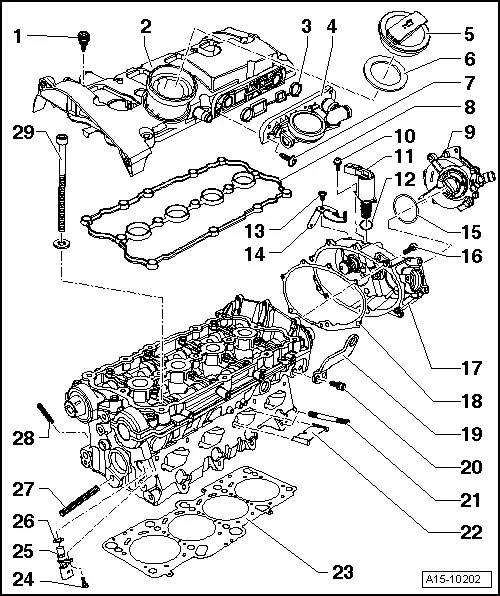

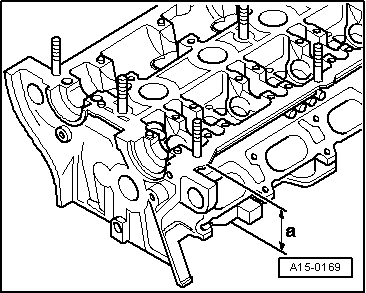

| Cylinder head - exploded view |

Note | t

| Renew the cylinder head bolts. |

| t

| On assembly, renew oil seals and gaskets as well as self-locking nuts and bolts that are tightened by turning through to a specified angle. |

| t

| When installing an exchange cylinder head with fitted camshafts, oil the contact surfaces between the roller rocker fingers and cams. |

| t

| The plastic protectors fitted to protect the open valves must only be removed immediately before fitting the cylinder head. |

| t

| When fitting a new cylinder head or cylinder head gasket, drain off all the old coolant and refill with new coolant. |

|

|

|

Note

Note