A4 Cabriolet Mk2

| Removing and installing camshafts |

| Special tools and workshop equipment required |

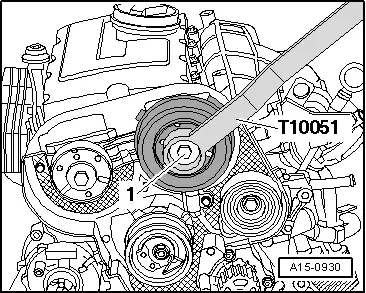

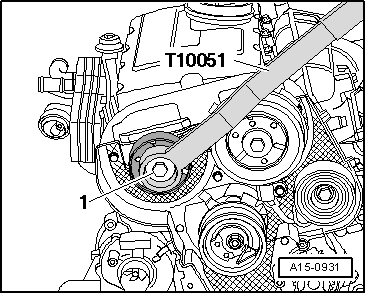

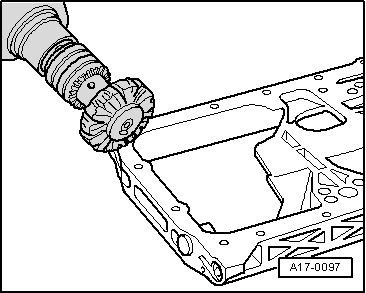

| t | Counterhold tool -T10051- |

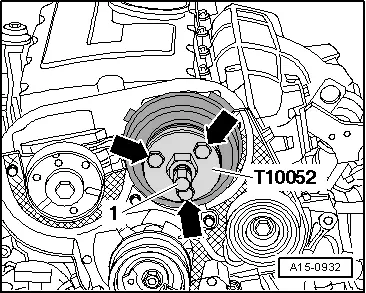

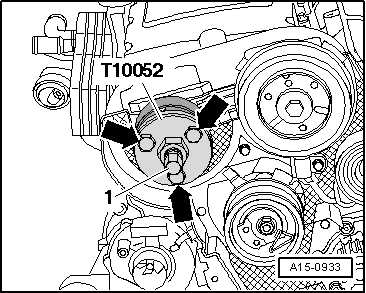

| t | Puller -T10052- |

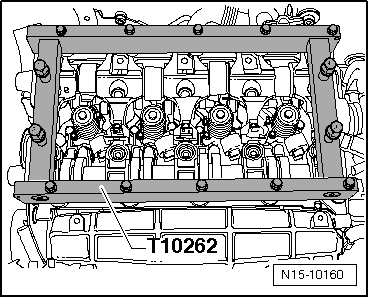

| t | Rack -T10262- |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

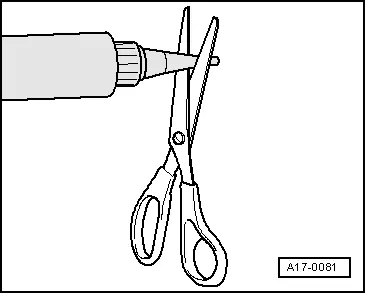

| t | Sealant → Electronic parts catalogue |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

| Component | Nm | ||||||

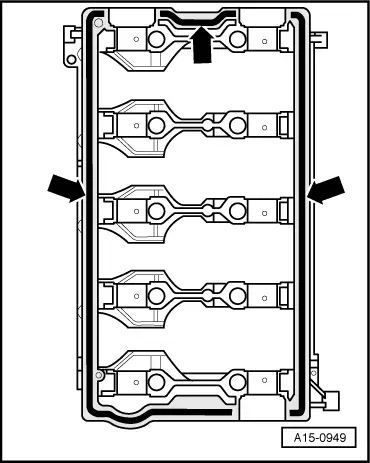

| Bearing frame to cylinder head | 20 | ||||||

| Rocker arm shaft to cylinder head | 20 + 90° 1)2) | ||||||

| Toothed belt cover (rear) to bearing frame | 10 3) | ||||||

| Bracket for exhaust gas recirculation cooler to cylinder head | 10 | ||||||

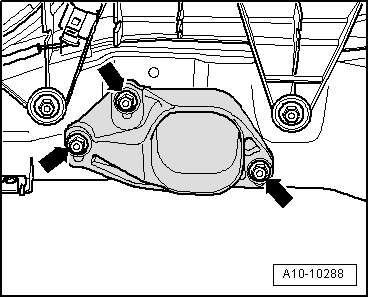

| Stop for torque reaction support to lock carrier | 28 | ||||||

| Hose clips (9 mm wide) | 3 | ||||||

| Hose clips (13 mm wide) | 5.5 | ||||||

| |||||||

Caution

Caution WARNING

WARNING