A4 Cabriolet Mk2

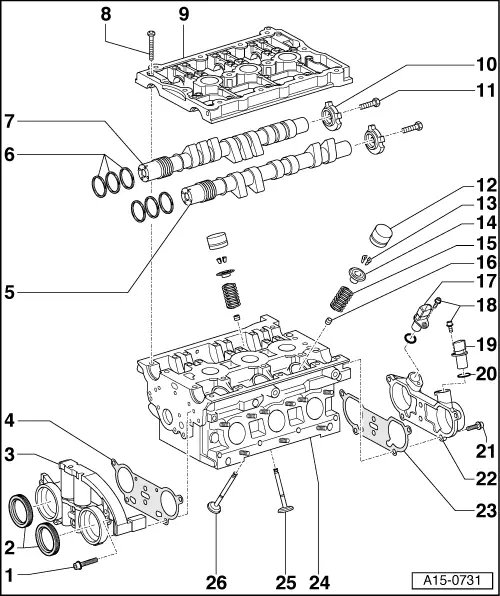

| Valve gear - exploded view |

Note

Note| Illustration shows left-side cylinder head. |

| 1 - | 10 Nm |

| 2 - | Oil seals |

| q | Renewing → Chapter |

| 3 - | Housing |

| q | For camshaft control valves |

| 4 - | Gasket |

| q | Renew |

| 5 - | Exhaust camshaft |

| q | Removing and installing → Chapter |

| q | Checking axial clearance → Chapter |

| q | Check with Plastigage (bucket tappets removed) |

| q | Radial clearance: wear limit: 0.1 mm |

| q | Runout: max. 0.01 mm |

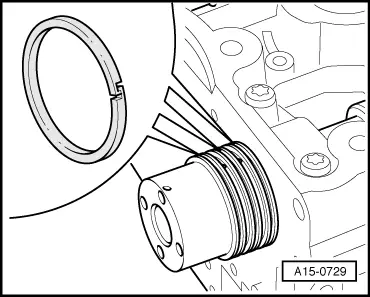

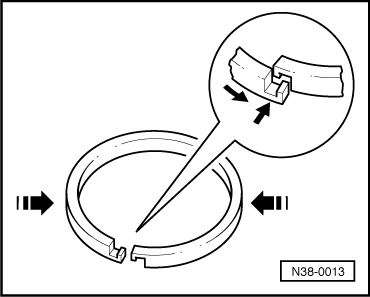

| 6 - | Compression rings for camshaft adjuster |

| q | Depending on version, some piston ring types are provided with lugs at the ends |

| q | Hook ends of compression rings together → Fig. |

| 7 - | Inlet camshaft |

| q | Removing and installing → Chapter |

| q | Checking axial clearance → Chapter |

| q | Check with Plastigage (bucket tappets removed) |

| q | Radial clearance: wear limit: 0.1 mm |

| q | Runout: max. 0.01 mm |

| 8 - | 10 Nm |

| q | Tighten in several stages, working from inside to outside |

| 9 - | Retaining frame |

| q | With integrated camshaft bearings |

| q | Removing and installing → Chapter „Removing and installing camshafts and camshaft adjuster“ |

| 10 - | Rotor for Hall sender |

| q | Note installation position (notch on camshaft) |

| 11 - | 23 Nm |

| 12 - | Hydraulic bucket tappet |

| q | Checking → Chapter |

| q | Removing and installing → Chapter „Renewing valve stem oil seals with cylinder head installed“ |

| q | Do not interchange |

| q | Place down with contact surface facing downwards |

| q | Check axial clearance of camshaft before installing → Chapter |

| q | Lubricate contact surface |

| 13 - | Valve cotters |

| 14 - | Valve spring plate |

| 15 - | Valve spring |

| 16 - | Valve stem oil seal |

| q | Renewing with cylinder head installed → Chapter |

| q | Renewing with cylinder head removed → Chapter |

| 17 - | Hall sender for inlet camshaft |

| q | Cylinder bank 1 (right-side): Hall sender -G40- |

| q | Cylinder bank 2 (left-side): Hall sender 2 -G163- |

| 18 - | 10 Nm |

| 19 - | Hall sender for exhaust camshaft |

| q | Cylinder bank 1 (right-side): Hall sender 3 -G300- |

| q | Cylinder bank 2 (left-side): Hall sender 4 -G301- |

| 20 - | O-ring |

| q | Renew |

| 21 - | 10 Nm |

| 22 - | Hall sender housing |

| 23 - | Gasket |

| q | Renew |

| 24 - | Cylinder head |

| q | See note → Chapter |

| q | Checking valve guides, grinding-in valve seats → Chapter |

| q | Machining valve seats → Chapter |

| 25 - | Inlet valve |

| q | Do not machine, only grinding-in is permitted |

| q | Mark installation position for re-installation |

| q | Valve dimensions → Chapter |

| q | Checking valve guides, grinding-in valve seats → Chapter |

| 26 - | Exhaust valve |

| q | Do not machine, only grinding-in is permitted |

| q | Mark installation position for re-installation |

| q | Valve dimensions → Chapter |

| q | Checking valve guides, grinding-in valve seats → Chapter |

|

|