A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

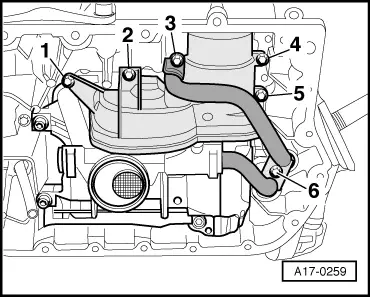

| Component | Nm | |||||||||

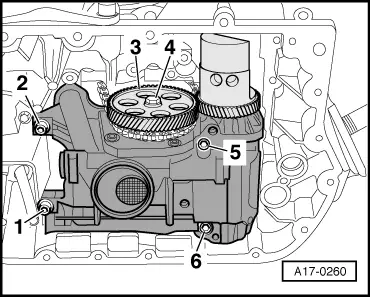

| Oil pump to cylinder block | Nuts | 20 + 120° 1)2) | ||||||||

| Bolts | 22 3) | |||||||||

| Drive gear for balance shaft to oil pump | 20 + 90° 3)4) | |||||||||

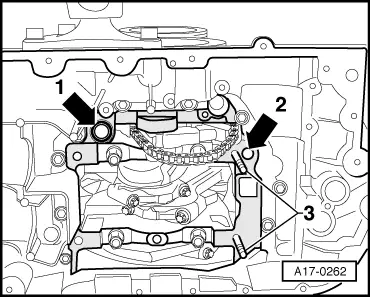

| Baffle plate (front) to sump (top section) | 10 | |||||||||

| Oil pressure pipe to sump (top section) | 10 | |||||||||

| Sealing plug in cylinder block | 25 | |||||||||

| ||||||||||

Caution

Caution