A4 Mk1

|

Removing and installing differential

Removing and installing differential

Special tools, testers and auxiliary equipment required

Notes:

|

|

|

|

|

|

|

|

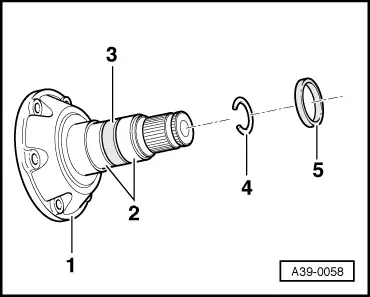

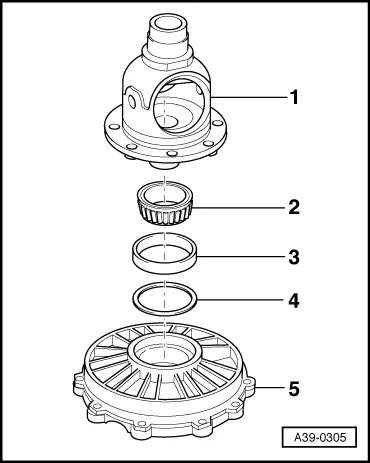

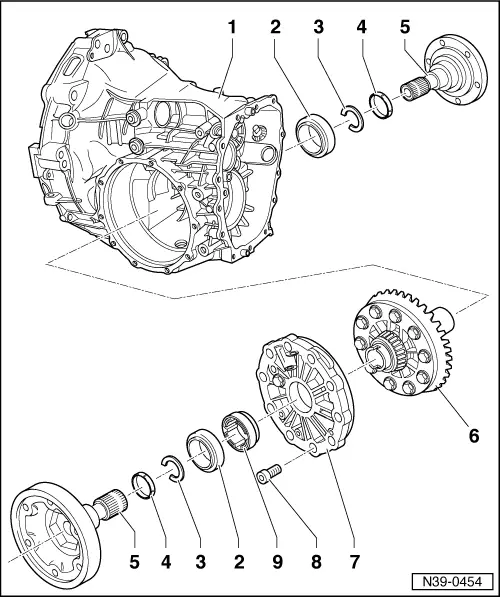

=> Parts List

|

|

|

|

|

|

|

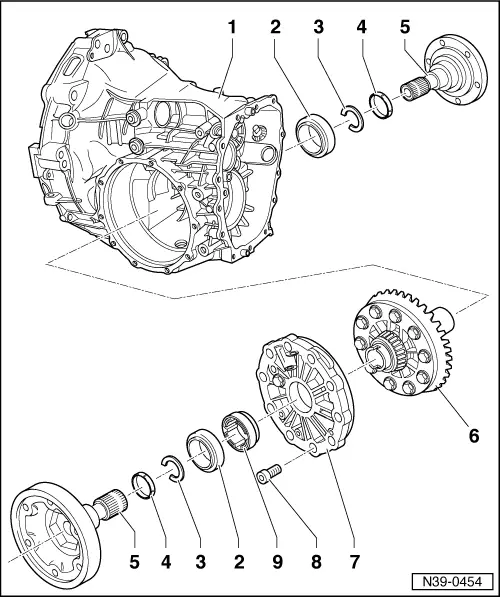

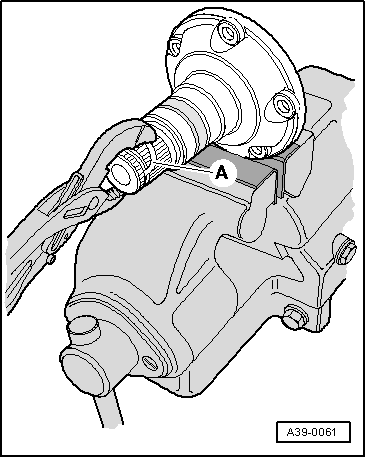

→ Fig.1 Removing and installing circlip

|

|

|

|

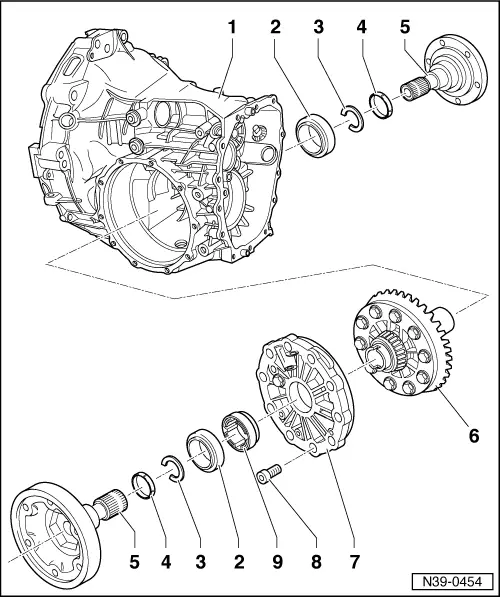

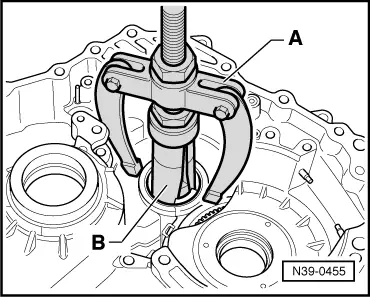

→ Fig.2 Removing spacer ring

|

|

|

|

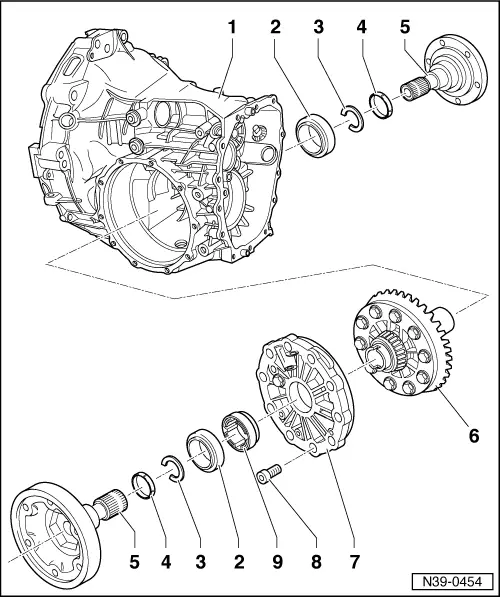

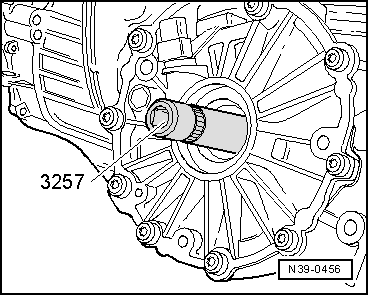

→ Fig.3 Installing spacer ring

|