A4 Mk1

|

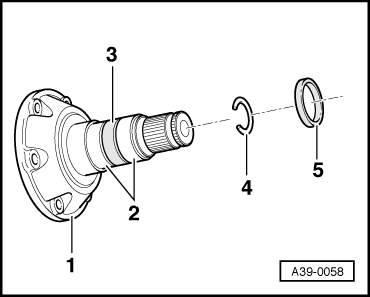

Renewing seal for flange shaft

Renewing seal for flange shaft

Special tools, testers and auxiliary equipment required

Notes:

Removing

=> Running Gear, Front and Four-wheel Drive; Repair Group 40; Removing and installing driveshaft

|

|

|

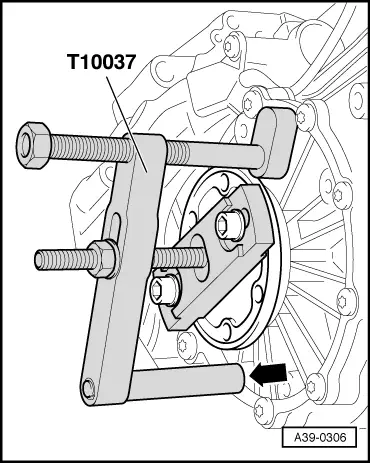

Note: In order to prevent damaging the needle roller bearing (polygon bearing) or the differential during removal, the flange shaft must be removed evenly, parallel and without applying one-sided force. Remove flange shaft (left).

|

|

|

|

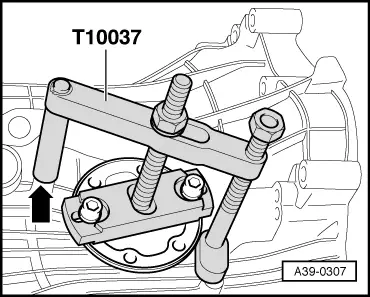

Remove the right flange shaft

|

|

|

|

|

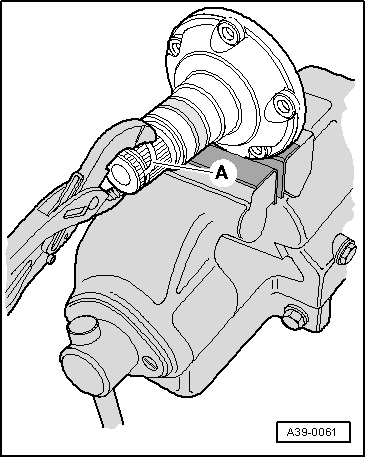

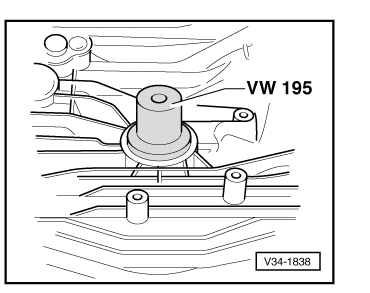

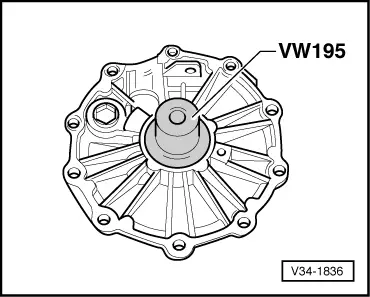

Note: If the old flange shaft is reinstalled after the repair, the oil seal must be knocked in to a depth of approx. 6.5 mm so that the new seal does not run on the same contact surface as the old one. |

|

|||||||||||||

Note: If the old flange shaft is reinstalled after the repair, the oil seal must be knocked in to a depth of approx. 6.5 mm so that the new seal does not run on the same contact surface as the old one.

Tightening torques

| |||||||||||||