A4 Mk1

|

|

|

Notes: |

|

|

|

|

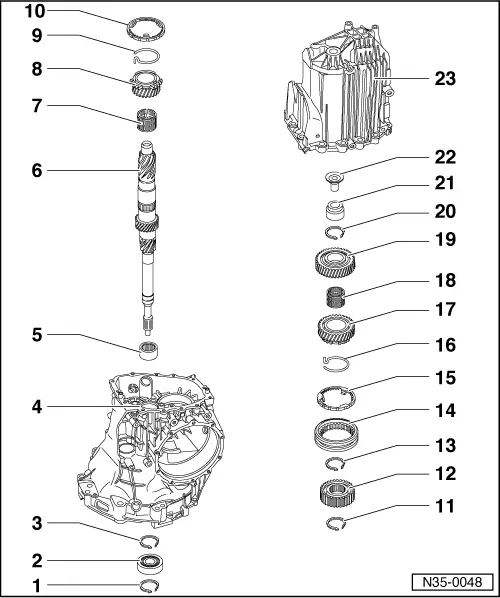

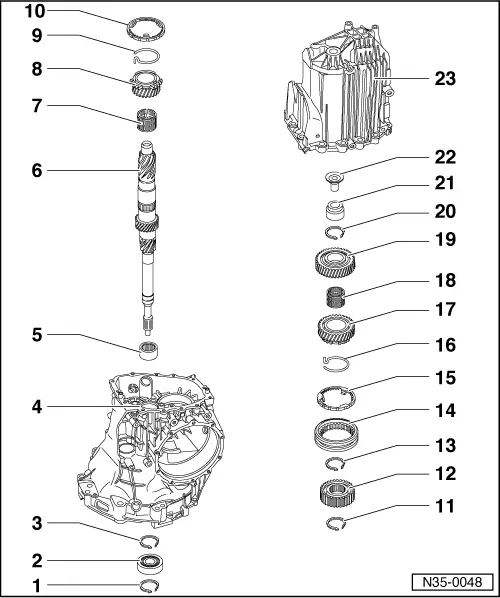

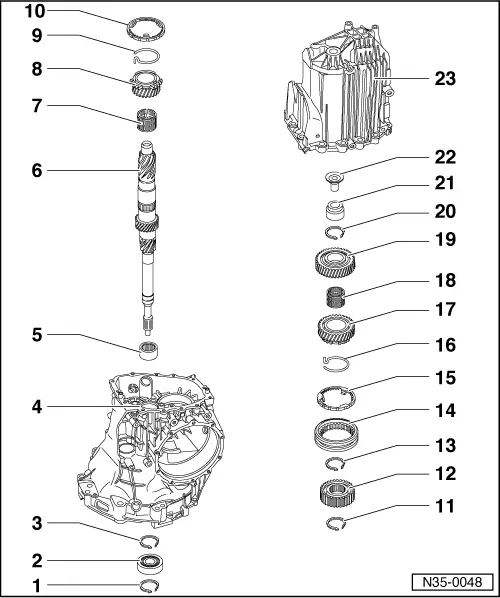

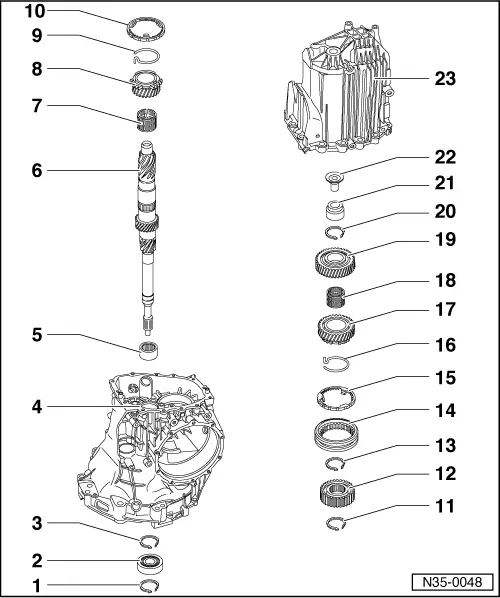

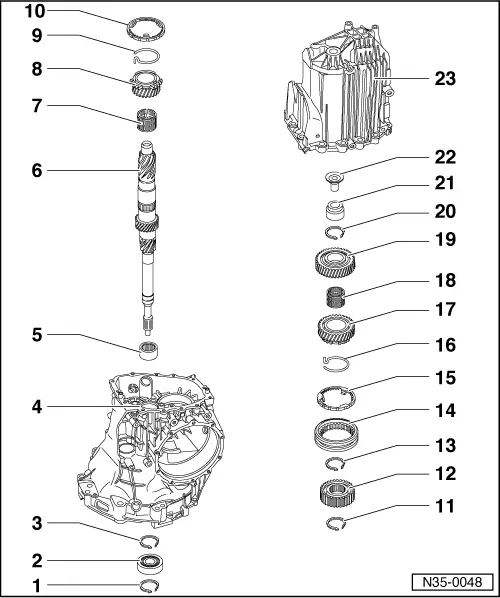

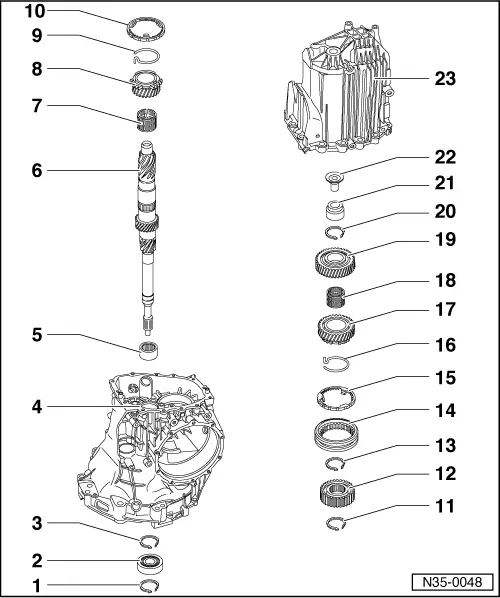

=> Parts List

|

|

|

|

|

|

=> Parts List |

|

|

|

|

|

|

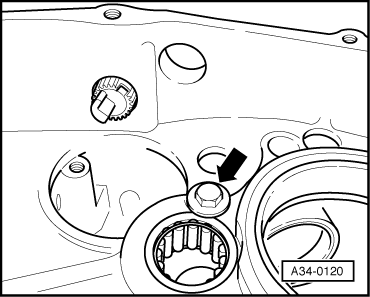

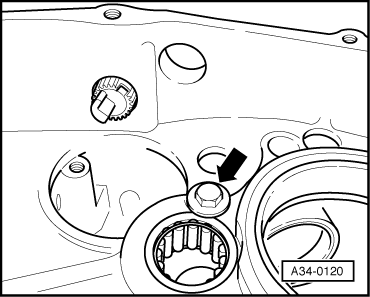

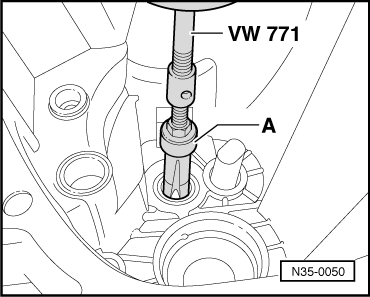

→ Fig.1 Unscrewing securing bolt -arrow- for needle roller bearing

Note: Bolt is not fitted on all versions. |

|

|

|

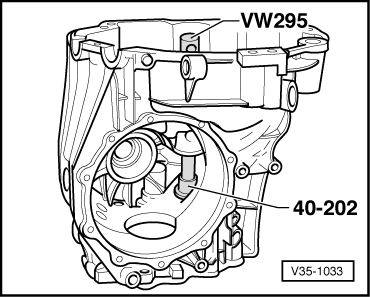

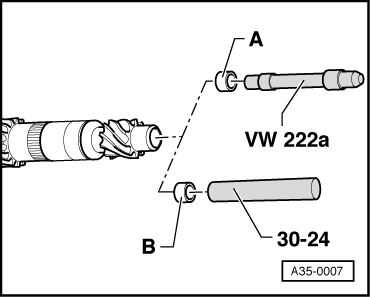

→ Fig.2 Driving out needle roller bearing |

|

|

|

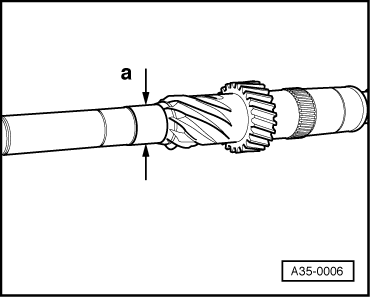

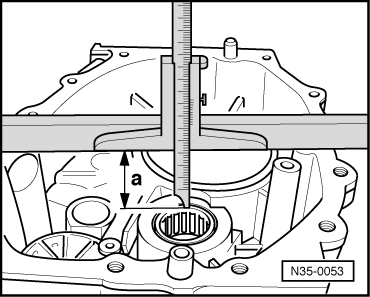

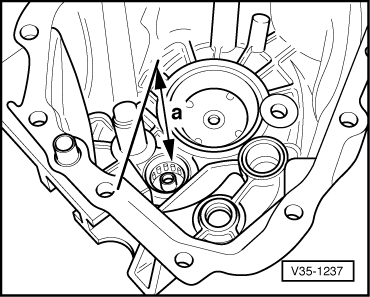

→ Fig.4 Installation position of needle roller bearing Distance -a- from lower edge of straight-edge to upper edge of needle roller bearing = 39.5 mm Note: Measure distance from top edge of straight-edge and subtract the width of the straight-edge from the measured distance. |

|

|

|

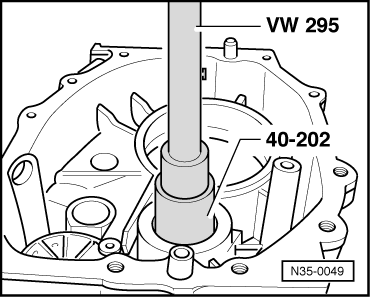

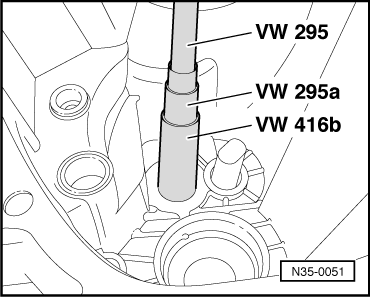

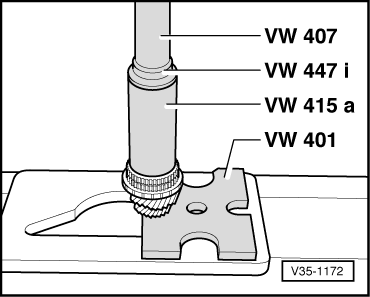

→ Fig.5 Pressing in needle roller bearing |

|

|

|

→ Fig.6 Screwing in securing bolt -arrow- Note: Bolt is not fitted on all versions.

|

|

||||||||||

|

→ Fig.7 Knocking oil feed sleeve into input shaft

|

|

|

|

→ Fig.8 Pulling out roller sleeve A - Internal puller, e. g. Kukko 21/4, 22 ... 28 mm

|

|

|

|

→ Fig.9 Installation position of roller sleeve

|

|

|

|

→ Fig.10 Driving in roller sleeve |

|

|

|

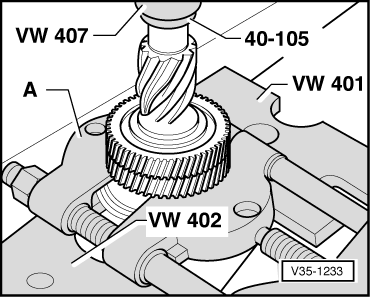

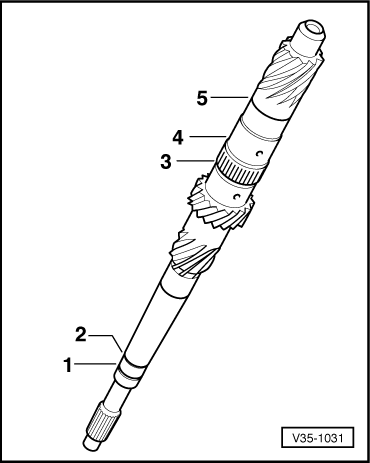

→ Fig.11 Pressing off 5th gear wheel

|

|

|

|

→ Fig.12 Pressing off synchro hub for 3rd and 4th gear

|

|

|

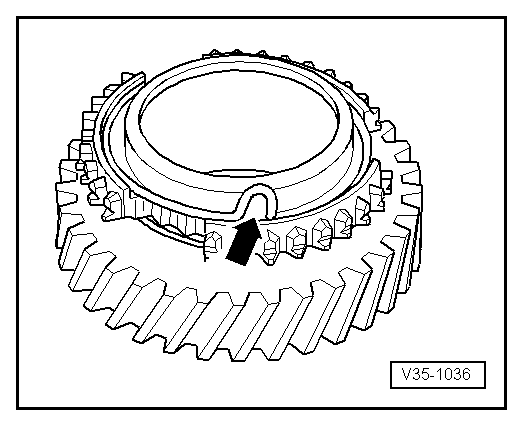

|

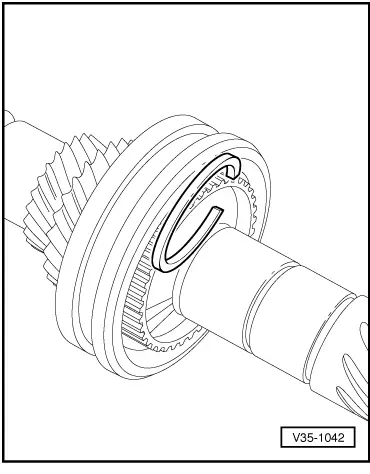

→ Fig.13 Inserting spring in sliding gear The bent end of the spring (arrow) must be hooked in the hole in the sliding gear. |

|

|

|

→ Fig.14 Checking synchro-ring for wear

The calculated value must not be less than 0.5 mm. |

|

|

|

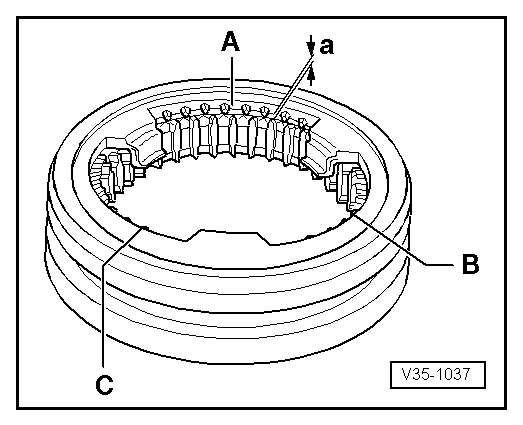

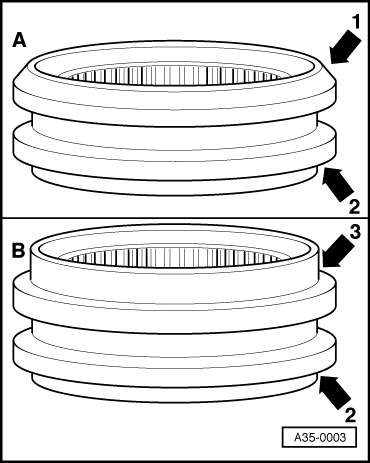

→ Fig.15 Installation position of circlips

|

|

||||||||||||||||||||

|

→ Fig.16 Determining thickness of circlip

=> Parts List Available circlips for 3rd and 4th gear synchro-hubs

Available circlips for 5th gear wheel

| ||||||||||||||||||||

|

|

|

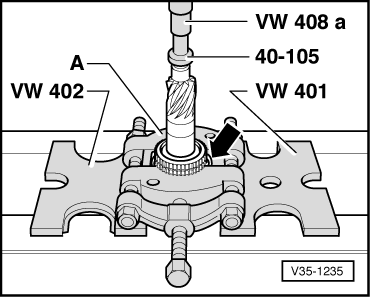

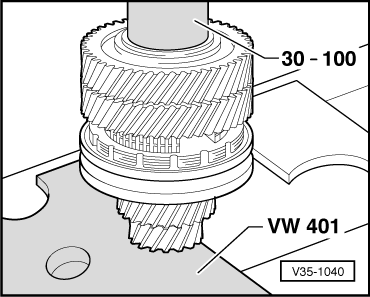

→ Fig.17 Pressing on synchro hub for 3rd and 4th gear

|

|

|

|

→ Fig.18 Installation position of locking collar Different types of locking collar are installed: version -A- with chamfered edge, arrow 1, or version -B- with large shoulder, arrow 3.

|

|

|

|

→ Fig.19 Pressing on 5th gear wheel Important:

Wear protective gloves!

|