-

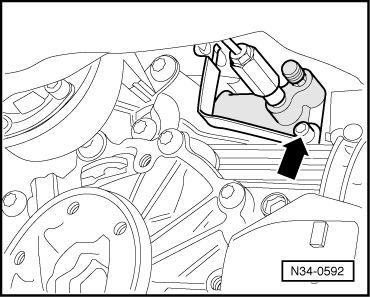

‒ → Lift gearbox until clutch slave cylinder with bracket for hose/pipe can be installed (arrow).

-

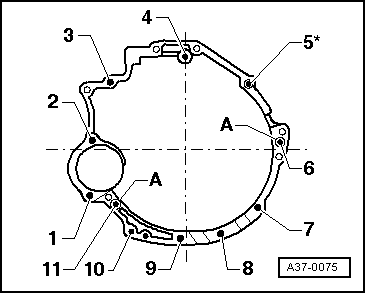

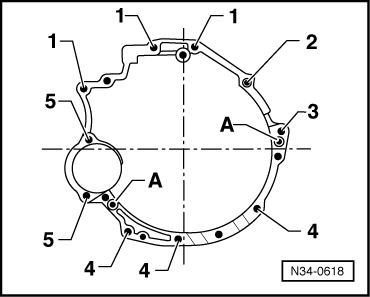

‒ If gearbox has intermediate plate, fit between gearbox and engine onto engine dowel sleeves.

-

‒ Ensure that the intermediate plate is correctly positioned on engine.

-

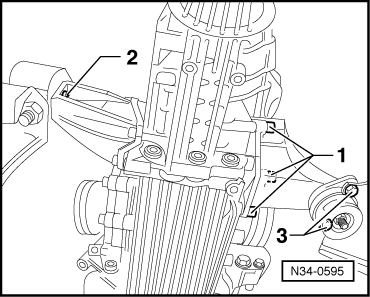

‒ Install lower engine/gearbox securing bolts and bolts for starter, to do this insert the starter.

=> Electrical system; Repair Group 27; Removing and installing starter

-

‒ The threaded bores in the flange shaft of the manual gearbox for the propshaft must be cleaned of remaining locking fluid with a thread tap before assembling

-

‒ Replace front gaskets at propshaft and at drive shafts.

-

‒ Bolt on propshaft => Page39-83

-

‒ Check adjustment of shift mechanism, adjust if necessary => Page 34-24.

-

‒ Stress free alignment of exhaust system

=> 4-cylinder Engine (5-valve), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

=> 4-cylinder Engine (5-valve turbo), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

=> 4-cylinder Diesel Direct Injection Engine (TDI), Mechanics; Repair Group 26; Removing and installing exhaust system

=> 6-cylinder Engine (2-valve), Mechanics; Repair Group 26; Removing and installing exhaust system

=> 6-cylinder Engine (5-valve), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

-

‒ Check oil level in gearbox => Page 34-69.

-

‒ After connecting battery, enter anti theft code for radio.

=> Radio operating instructions

-

‒ Close windows fully using electric window switches.

-

‒ Then actuate all electric window switches again for at least one second in the "close" direction to activate the automatic open/close function.

-

‒ Set clock to correct time.

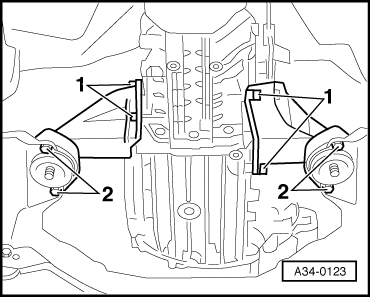

Tightening torques

|