A4 Mk1

|

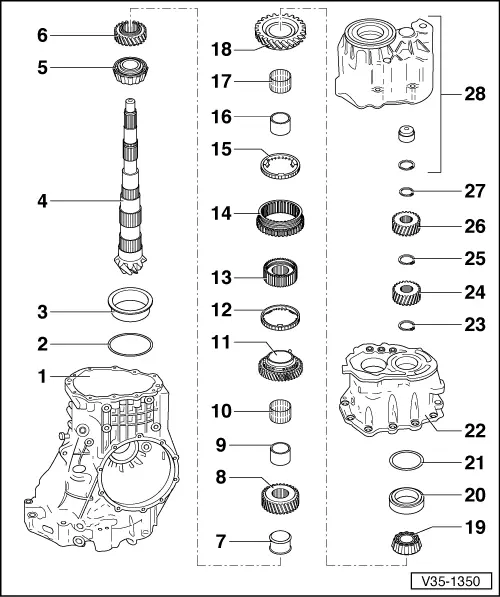

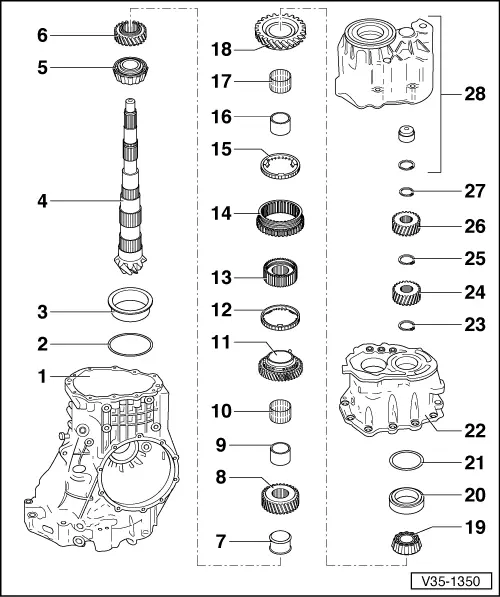

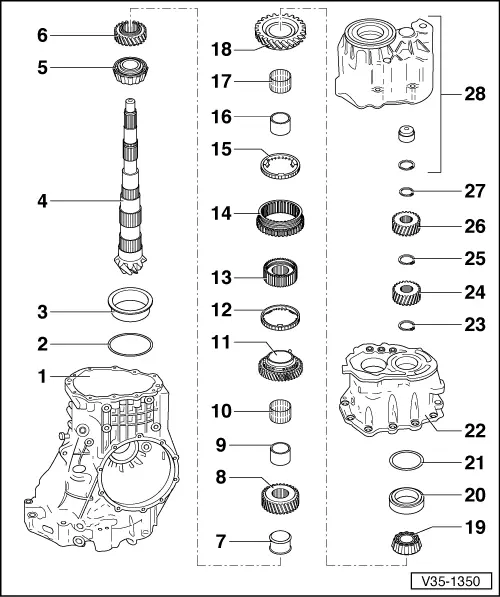

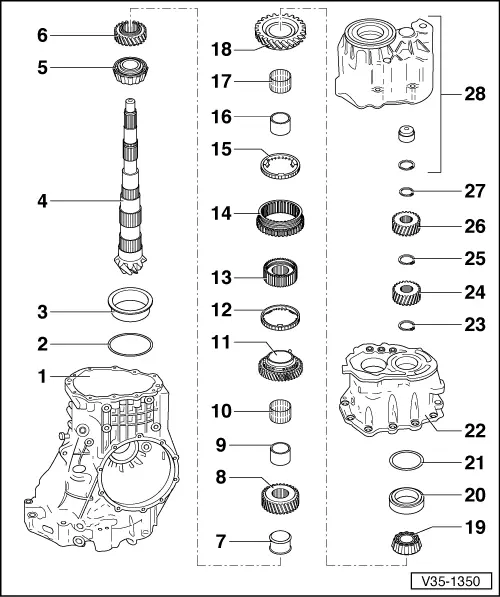

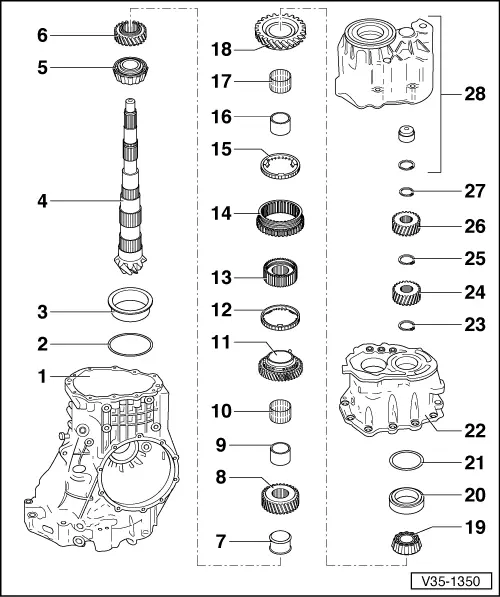

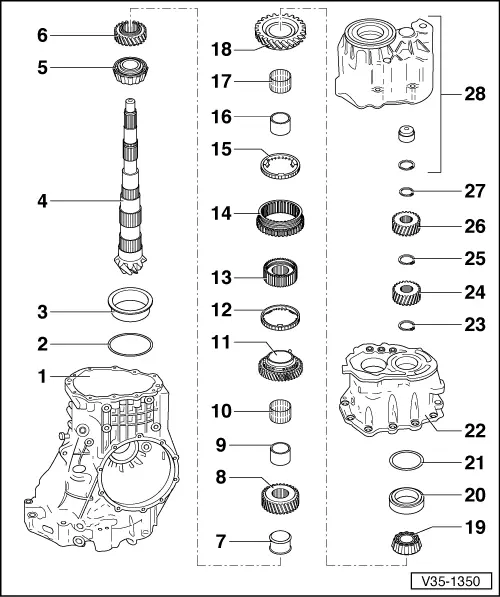

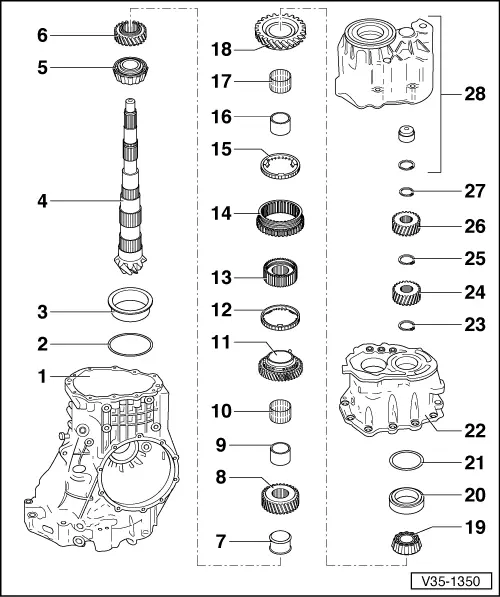

Dismantling and assembling drive pinion

Dismantling and assembling drive pinion

|

|

|

|

Notes: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

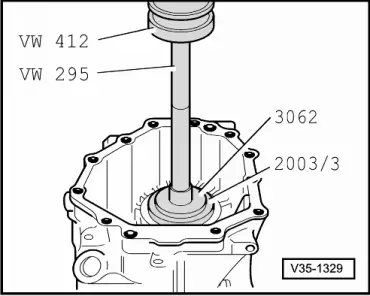

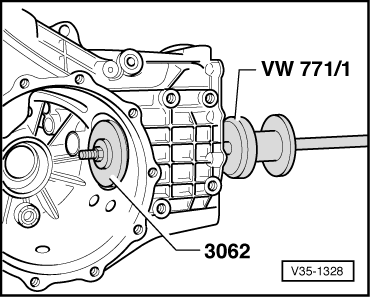

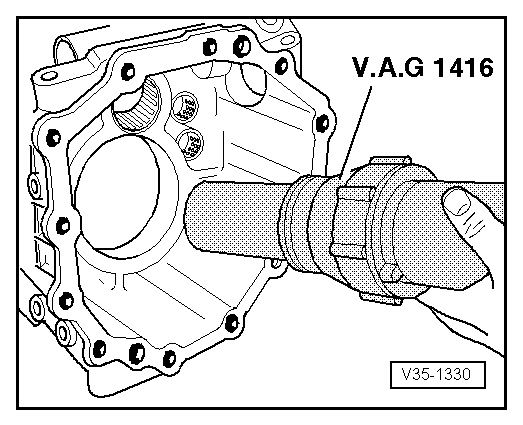

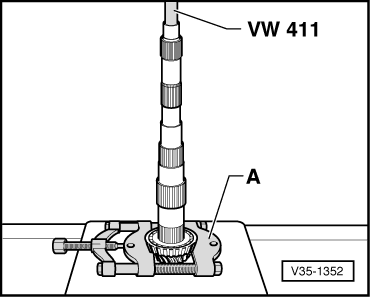

→ Fig.1 Pulling out outer race for large taper roller bearing

|

|

|

|

→ Fig.2 Heating gearbox housing in order to fit taper roller bearing outer race

|

|

|

|

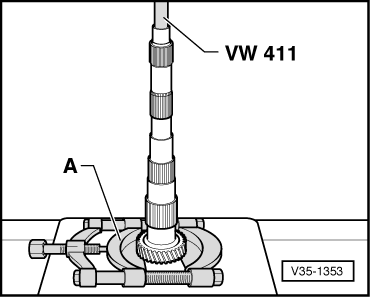

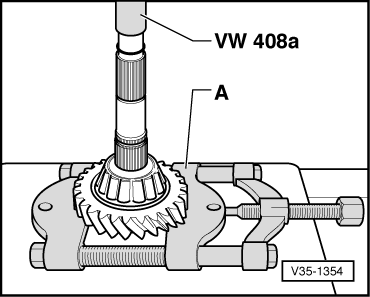

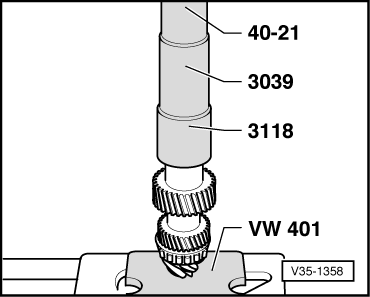

→ Fig.4 Pressing off inner race of small taper roller bearing for drive pinion together with 1st speed sliding gear

|

|

|

|

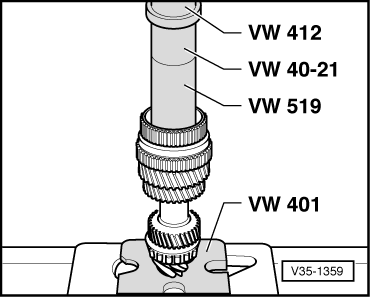

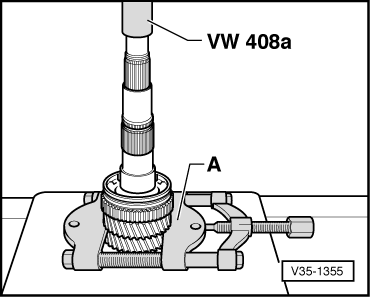

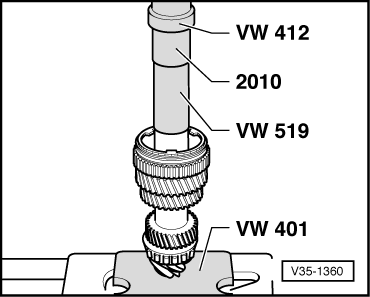

→ Fig.5 Pressing off 2nd speed sliding gear with locking collar/synchro-hub for 1st and 2nd speed gear and inner race for 1st speed sliding gear

|

|

|

|

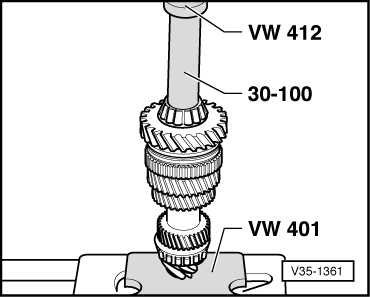

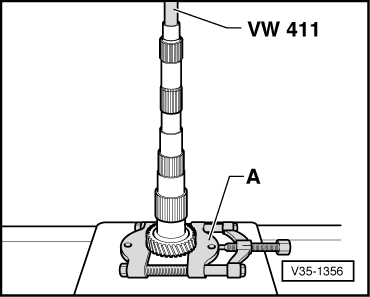

→ Fig.6 Pressing off 3rd speed gear together with inner race for 2nd speed sliding gear

|

|

|

|

→ Fig.8 Pressing off inner race for large taper roller bearing

|

|

|

|

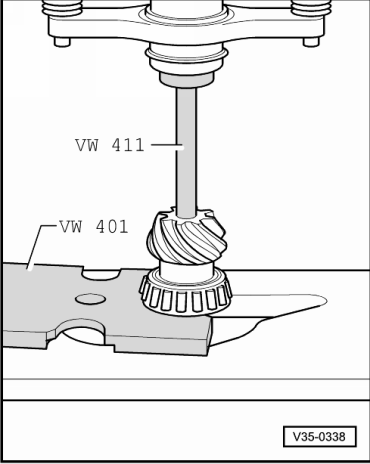

→ Fig.9 Pressing on inner race for large taper roller bearing

|

|

|

|

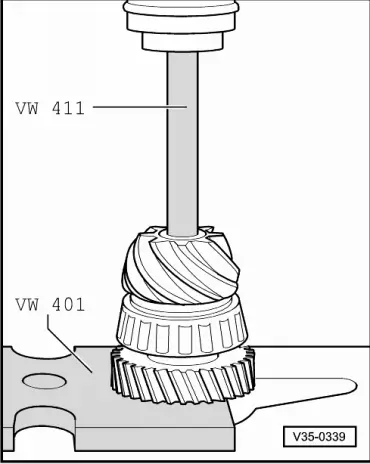

→ Fig.10 Pressing on 4th speed gear

|

|

|

|

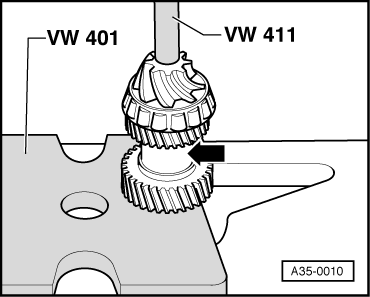

→ Fig.11 Pressing on 3rd speed gear

|

|

|

|

→ Fig.12 Pressing on inner race for 2nd speed sliding gear

|

|

|

|

→ Fig.14 Pressing on inner race for 1st speed sliding gear

|

|

|

|

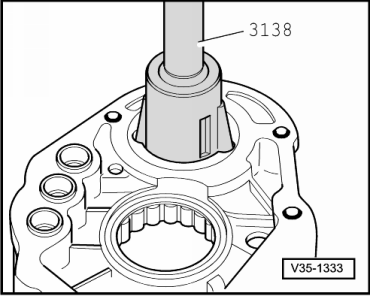

→ Fig.16 Driving out outer race for small taper roller bearing |

|

|

|

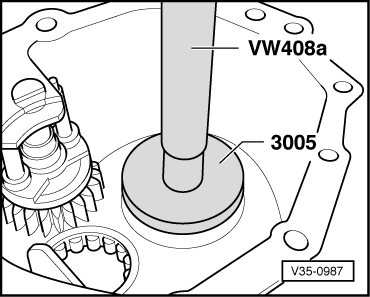

→ Fig.17 Pressing in outer race for small taper roller bearing

|