A4 Mk1

|

Dismantling and assembling planetary gearbox

IV - Adjusting 2nd and 4th gear brake -B2-

|

|

|

|

→ There are two types of gearboxes: |

|

|

|

Special tools and workshop equipment required

|

|

|

|

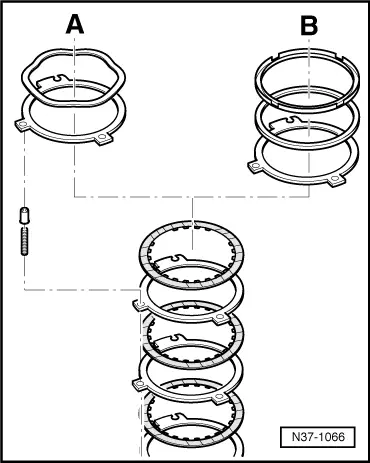

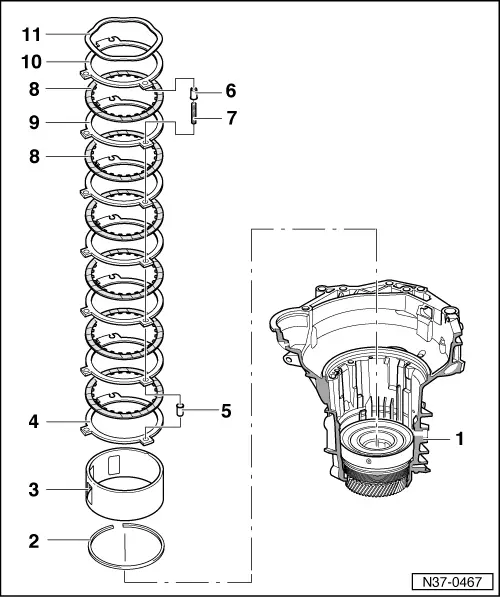

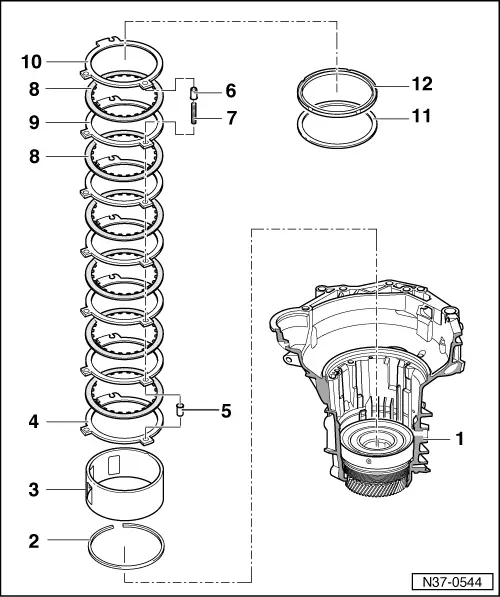

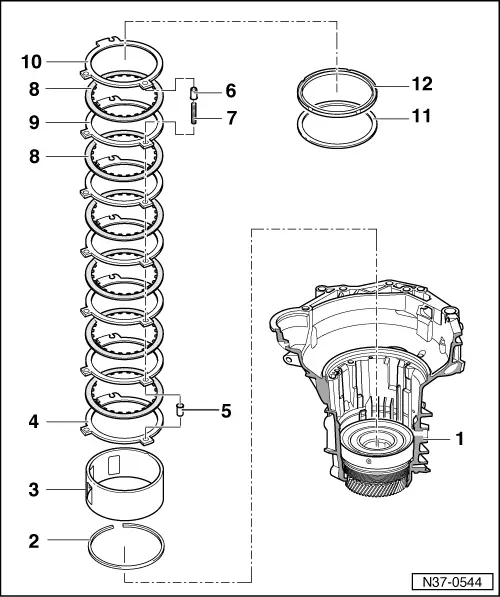

Adjusting 2nd and 4th gear brake -B2- This adjustment instruction is only valid for gearboxes where a corrugated spring washer in brake -B2- on the last outer plate is installed (=> Items 10 and 11). Gearbox code letters => from Page 00-3. On these gearboxes the play of brake -B2- is determined by the thickness of the last outer plate(s) -Item 10-. Note: Adjusting gearboxes without corrugated spring washer. |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

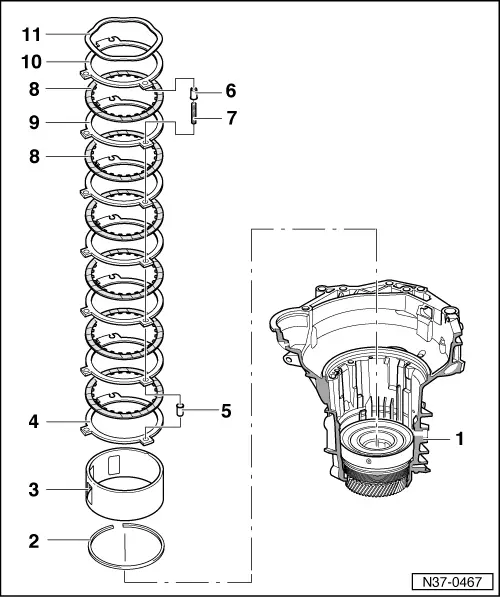

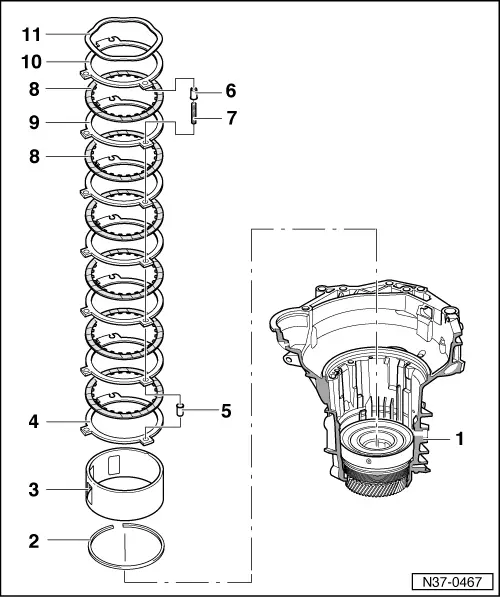

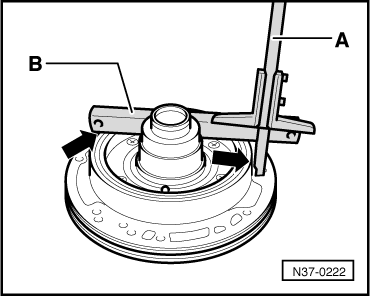

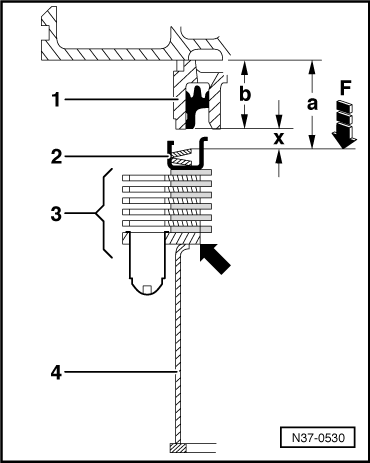

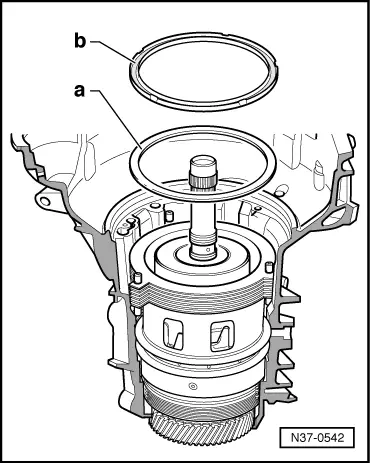

Calculating thickness of last outer plate -D- → The thickness of the outer plate(s) is determined by gap "x". Gap "x" is calculated using the following formula: x = a - b - 3.6 mm

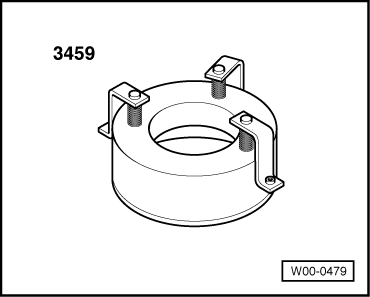

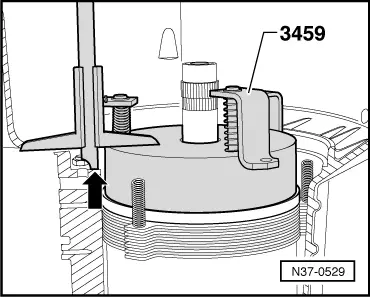

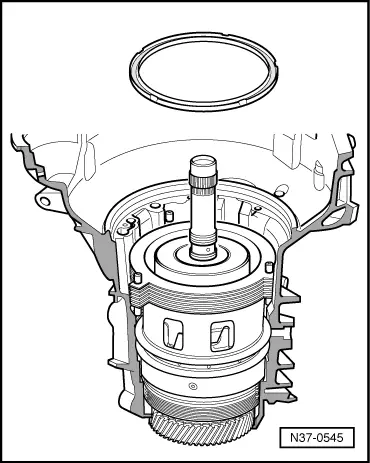

The illustration shows a cross-section of the brake -B2- in assembled form. Special tool 3459, which exerts a force onto the set of plates, is not illustrated. 3.6 mm is the allowance for settling resulting from the force exerted by special tool 3459. Note: The first outer plate -arrow- is 3 mm thick. Calculating measurement "a" Assemble planetary gearbox up to the last -B2- inner plate,

|

|

||||||

|

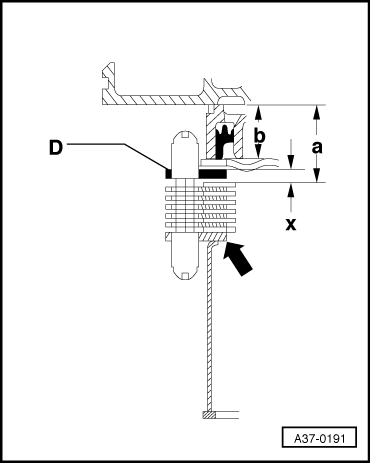

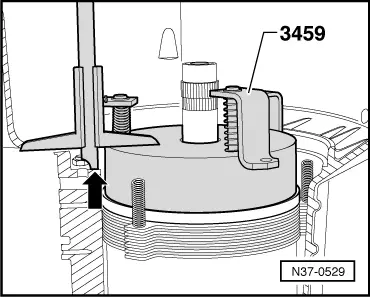

Note: The plate set for -B2- is now pressed together for measurements.

Dimension a = Height of 3459 in mm - measured value Example:

|

|

|||||||||||||||||||||||||||||||

|

Calculating measurement "b"

Example:

x = a - b - 3.6 mm = 30.2 mm - 20.6 mm - 3.6 mm = 6.0 mm

=> Parts catalogue Table of outer plates -D-

|

|

|

|

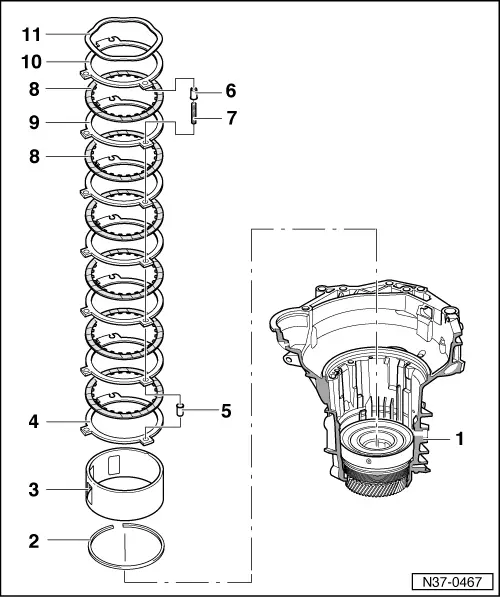

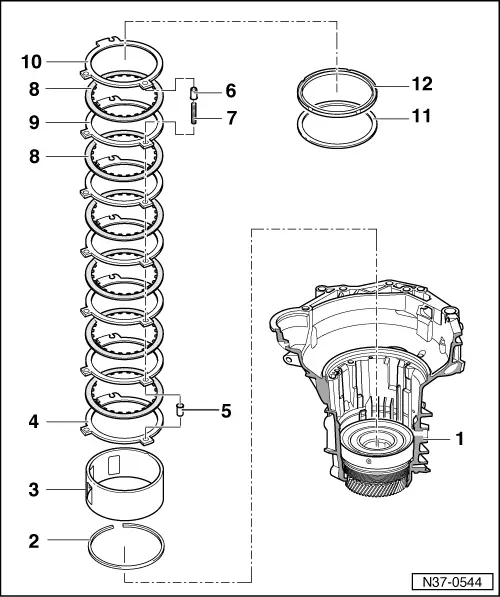

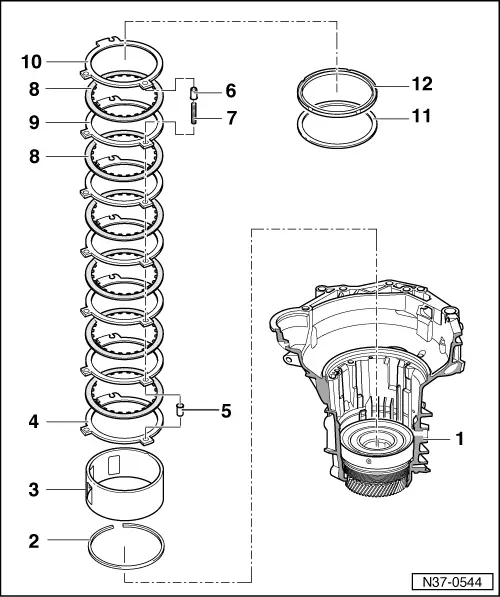

Adjusting 2nd and 4th gear brake -B2- These adjustment procedures are only valid for gearboxes with a shim and retaining ring installed in brake -B2- Gearbox code letters => from Page 00-3. In these gearboxes the play in brake -B2- is determined by the thickness of the shim -Item 11-. Note: Adjusting gearboxes with corrugated spring washer=> Page 37-157. |

|

|

|

|

|

|

|

|

|

|||||||||

|

→ Determining thickness of shim(s) The thickness of the shim depends on the size of gap "x". Gap "x" is calculated using the following formula: Gap x = a - b - 2.65 mm

The illustration shows a cross-section of the brake -B2- in assembled form. Special tool 3459, which exerts a force -F- onto the set of plates, is not illustrated. 2.65 mm - The amount for settling is taken into account by force F.

Notes:

|

|

|

|

Calculating "a": Assemble planetary gearbox up to the last -B2- inner plate, => Page 37-113. The last outer plate and shim are not installed.

Note: The plate set for -B2- is now pressed together for measurements. |

|

||||||

Dimension a = Height of 3459 in mm - measured value Example:

|

|

|

|