-

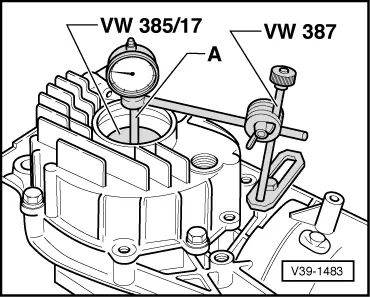

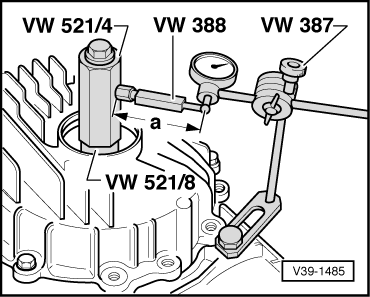

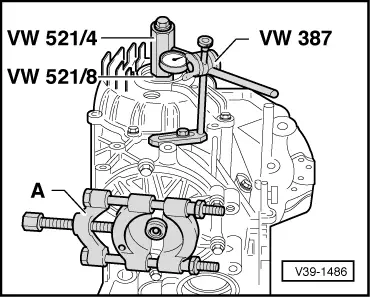

‒ → Fit separating device -A- (e.g. Kukko 17/2) if drive pinion turns whilst turning differential so that an exact backlash can be measured.

-

‒ Loosen locking screw of VW 521/4. Then turn crown wheel through a further 90°and repeat complete measuring process another 3 times. Add the four measured values together and calculate average backlash.

Determining average backlash

-

‒ Add the four measured values together and divide by four.

|

Example:

|

|

|

|

1st measurement

|

0.49 mm

|

|

+

|

2nd measurement

|

0.48 mm

|

|

+

|

3rd measurement

|

0.50 mm

|

|

+

|

4th measurement

|

0.49 mm

|

|

=

|

Sum of measured values

|

1.96 mm

|

-

● Result: the average backlash is 1.96 mm /4 = 0.49 mm.

If the individual measurements differ by more than 0.06 mm this means that the installation of the crown wheel is not correct or that the crown wheel and pinion themselves are defective. Recheck the installation, and if necessary renew crown wheel and pinion.

Determining thickness of shim"S2"

-

‒ Multiply the backlash figure by 1.17 (constant value), subtract the result from the thickness of the already inserted shim "S2" (1.50 mm in example), and add 0.20 mm for lift (constant value).

|

|

|---|

|

"S2"

|

=

|

"S2*" - backlash + lift

|

|

|

|---|

|

Example:

|

|

|

|

Installed shim(s) "S2*"

|

1.50 mm

|

|

-

|

Average backlash

(0.49 mm) x 1.17

|

0.57 mm

|

|

+

|

Lift (constant)

|

0.20 mm

|

|

=

|

Thickness of shim "S2"

|

1.13 mm

|

-

‒ Determine shim(s) as accurately as possible from table. Part numbers

=> Parts catalogue

The following shims are available for "S2"

|

|

|---|

|

Shim thickness (mm) 1)

|

|

0.55

|

0.75

|

0.95

|

|

0.60

|

0.80

|

1.00

|

|

0.65

|

0.85

|

1.05

|

|

0.70

|

0.90

|

|

1) Using the shim tolerance variations it is possible to find the exact shim thickness required, insert two shims if necessary.

Determining thickness of shim "S1"

|

Example:

|

|

|

|

Total thickness "Stotal"

for "S1" + "S2"

|

2.50 mm

|

|

-

|

Thickness of shim "S2"

|

1.13 mm

|

|

=

|

Thickness of shim "S1"

|

1.37 mm

|

-

‒ Determine shim(s) as accurately as possible from table. Part numbers

=> Parts catalogue

The following shims are available for "S1"

|

|

|---|

|

Shim thickness (mm) 1)

|

|

0.55

|

0.75

|

0.95

|

|

0.60

|

0.80

|

1.00

|

|

0.65

|

0.85

|

1.05

|

|

0.70

|

0.90

|

|

1) Using the shim tolerance variations it is possible to find the exact shim thickness required, insert two shims if necessary.

|