A4 Mk1

|

Removing and installing gearbox

Removing

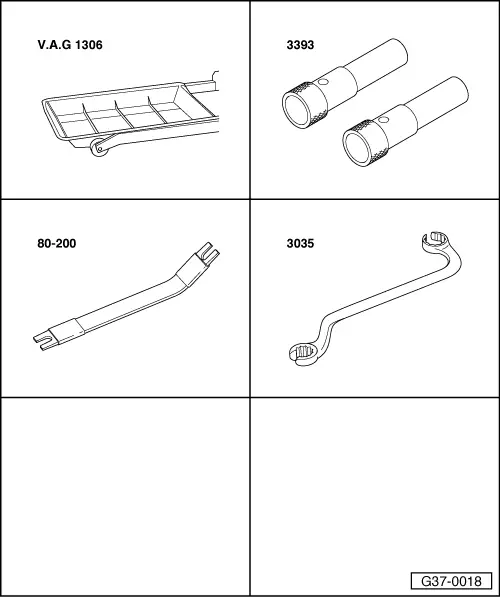

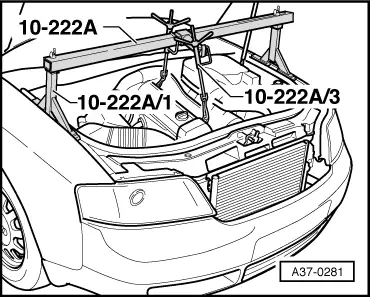

The following special tools and testing devices are required:

|

|

|

Additionally required information

|

|

|

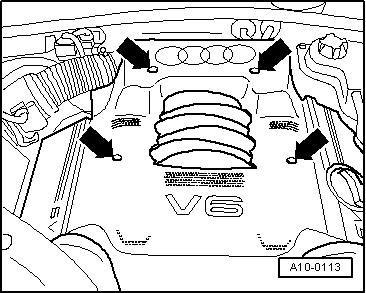

For 6-cylinder petrol engines except 2.7l 5V turbo-charged engine:

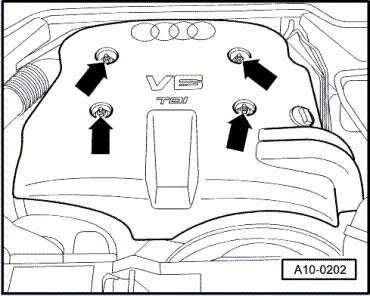

For 6-cyl. diesel direct injection engines (TDI) |

|

|

The remaining procedure for removing and installing the gearbox on 2.7l 5V turbo-charged engines is described from Page => 37-99 onwards. |

|

|

|

All except 2.7l 5V turbo engine:

|

|

|

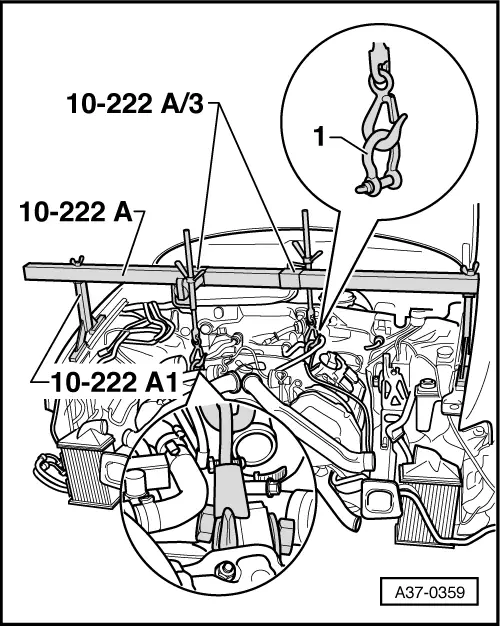

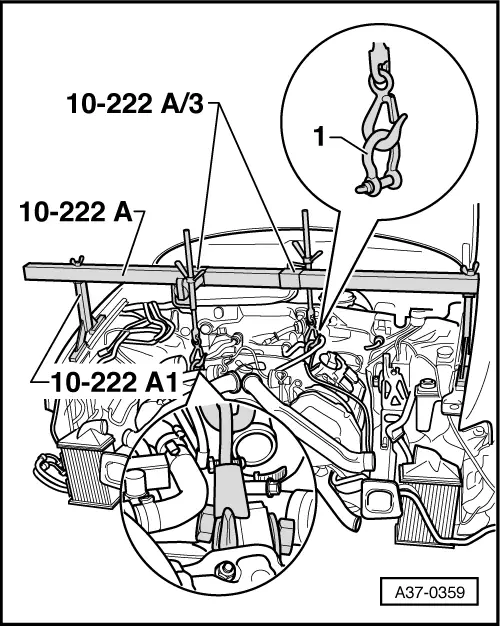

On all 6-cylinder engines:

|

|

|

For 4-cylinder engines: |

|

|

|

|

|

All models: |

|

|

|

|

|

=> Running Gear, Front and Four-wheel Drive; Repair group 40; Removing and installing drive shaft |

|

|

|

|

|

|

|

|

|

For 6-cylinder engines except 2.7l 5V turbo-charged engine:

|

|

|

|

|

|

|

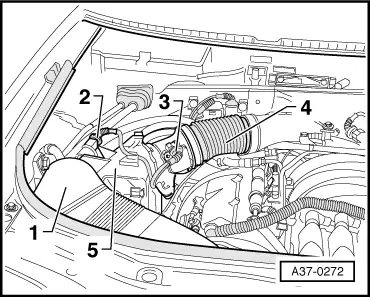

Vehicles with 4-cylinder engine

All except 2.7l 5V turbo engine: |

|

|

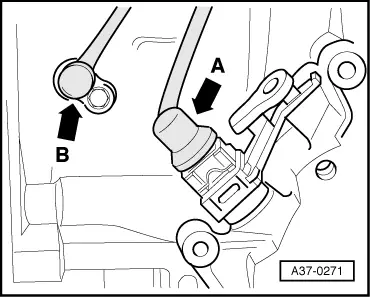

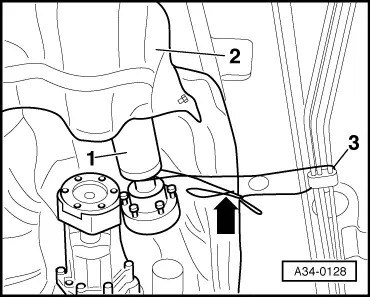

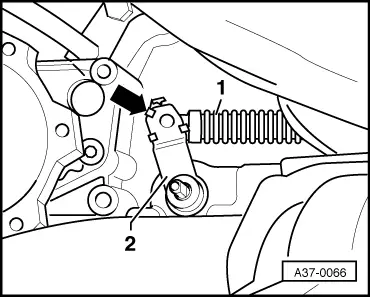

=> Electrical System; Repair group 27; Removing and installing starter Separate the torque converter from the drive plate. Foe vehicles with hexagon bolts:

|

|

|

|

For vehicles with Torx bolts:

Vehicles with four-wheel drive |

|

|

|

|

|

|

|

|

|

Continued for all vehicles

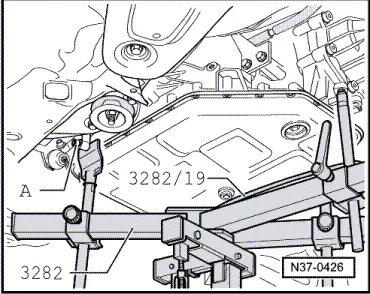

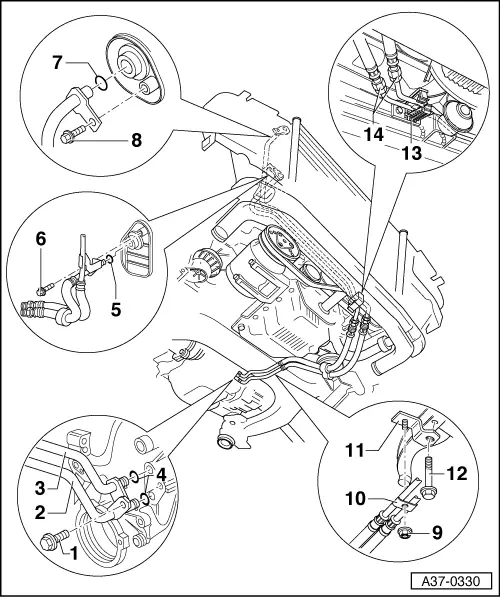

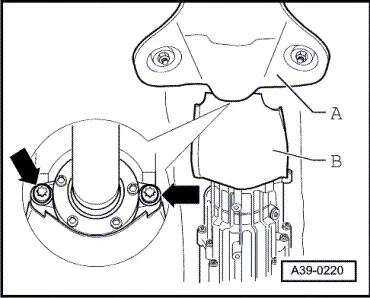

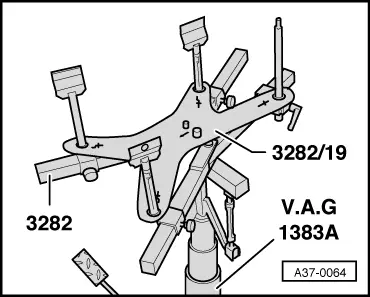

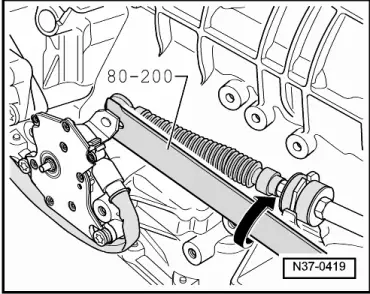

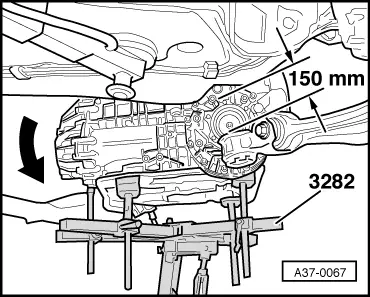

The gearbox support 3282 is aligned with the adjusting plate 3282/2 for removing the automatic gearbox 01V. The symbols on the adjusting plate indicate the mounts required, the arrow points forward. |

|

|

|

|

|

|

|

|

|

|

|

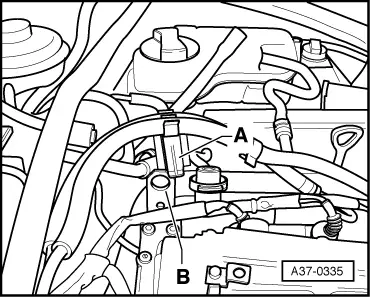

For 6-cylinder TDIengines |

|

|

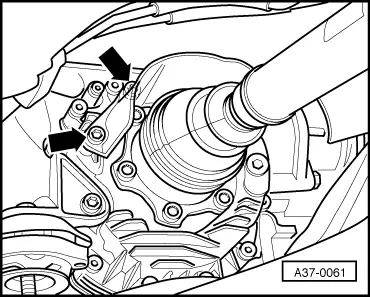

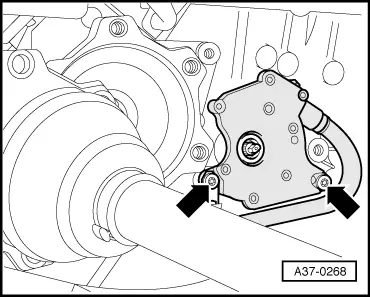

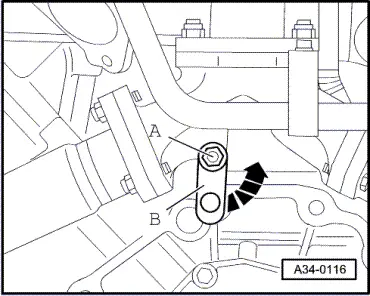

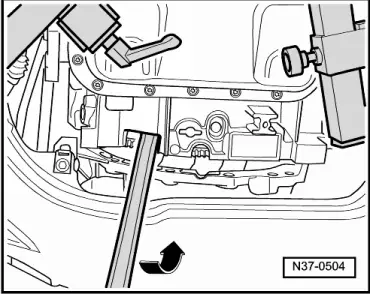

Note: The illustration shows the engine from the rear with the gearbox removed. Continued for all vehicles |

|

|

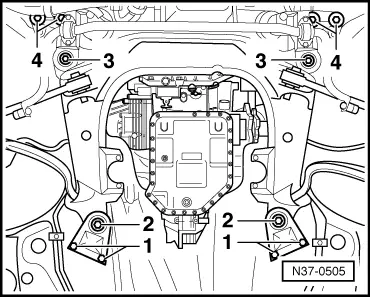

If this is not the case, check axle alignment after installing the subframe. |

|

|

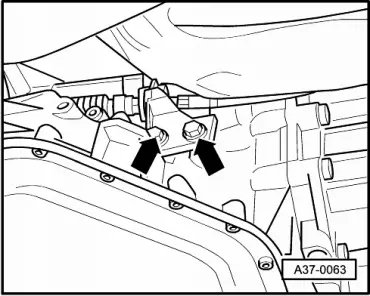

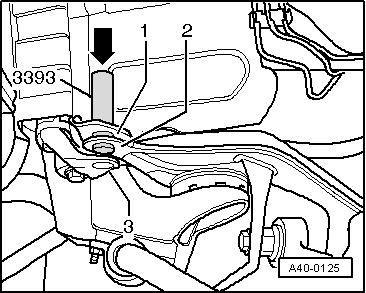

The subframe is lowered by approx. 150 mm by releasing bolts on rear edge => Page 37-88, Fig. A37-0067.

|

|

|

|

|

|