A4 Mk1

|

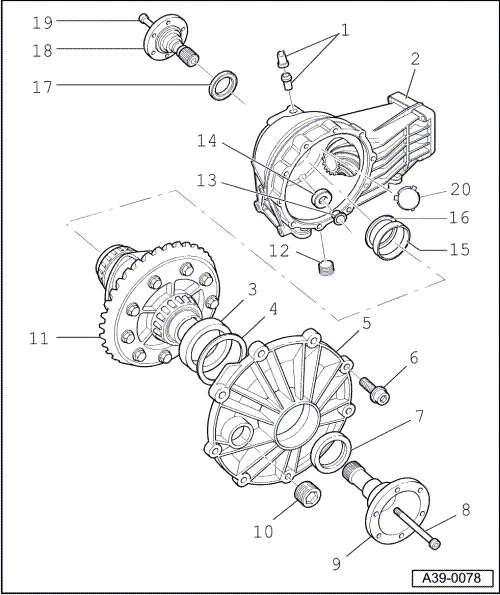

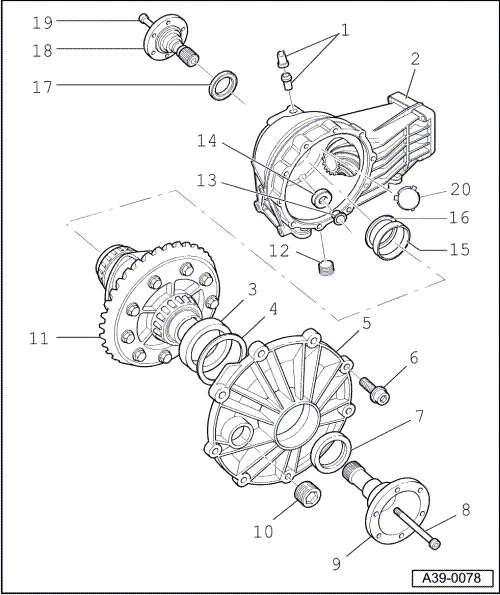

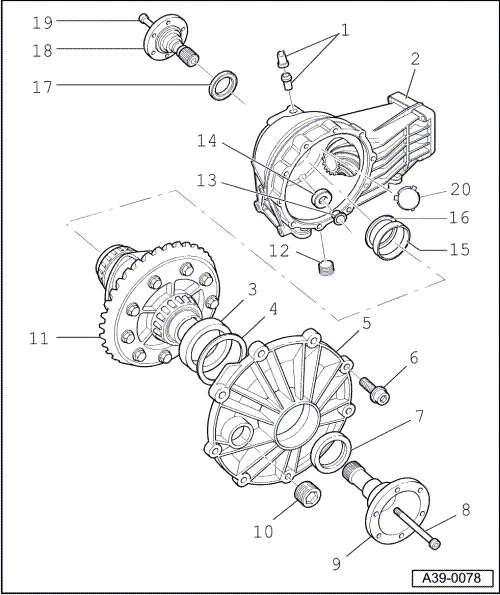

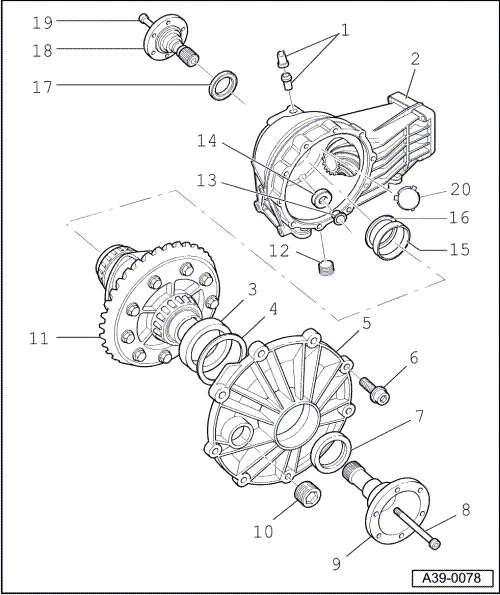

Removing and installing differential

Removing and installing differential

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

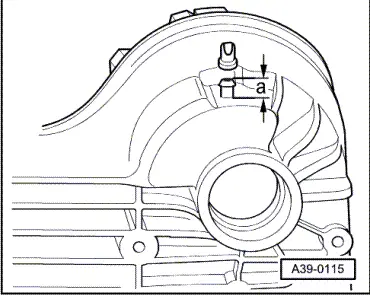

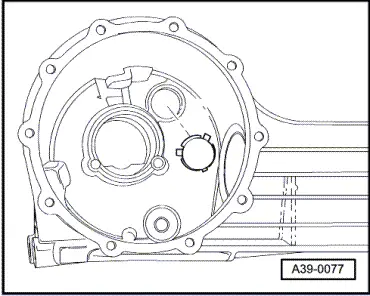

→ Fig2 Press in cover until stop |

|

|

|

Removing and installing differential

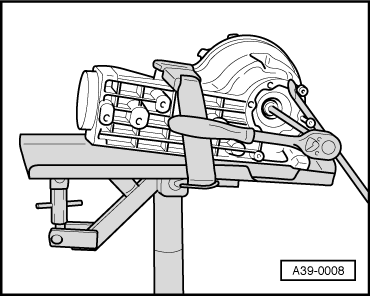

Special tools, testers and auxiliary equipment required

Removing

|

|

|

|