-

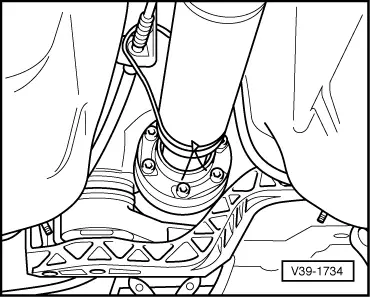

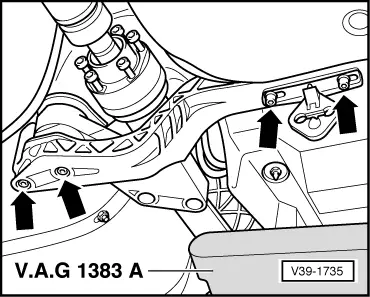

‒ → Secure propshaft to handbrake cable bracket with wire.

Note:

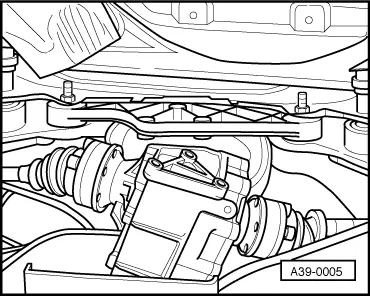

If it is not possible to push propshaft up and off flange, lower final drive before tying up propshaft. When lowering final drive, prevent propshaft from dropping down, and do not bend centre joint further than maximum angle permitted => notes on Page 39-74.

-

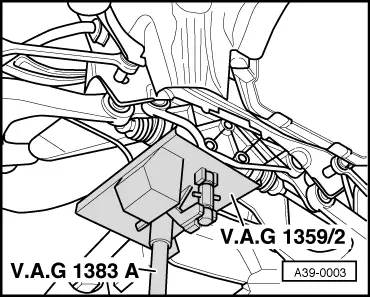

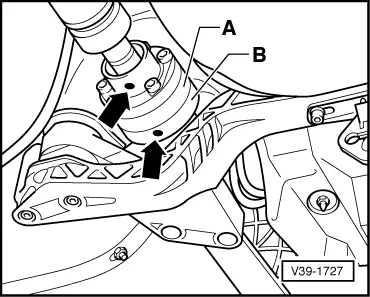

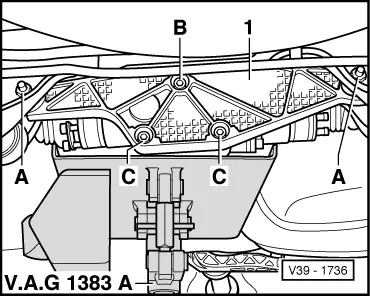

‒ Detach left and right drive shafts from rear final drive

=> Running Gear, Front and Four-wheel Drive; Repair group 42; Arrangement of Rear Axle Components (vehicles with 4WD); Removing and installing drive shaft

|