|

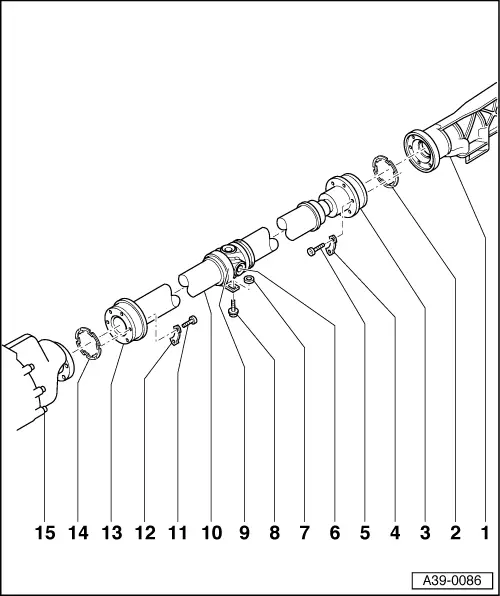

Servicing propshaft

Servicing propshaft

Notes:

-

◆ General repair instructions .

-

◆ Do not kink the propshaft - the maximum permissible bending angle is 25 °. The universal joint could otherwise be damaged.

-

◆ Only store and transport propshaft extended.

-

◆ No repair work can be carried out on the propshaft with the exception of removing, installing and adjusting.

-

◆ If the propshaft is only detached at the gearbox or from rear final drive then the propshaft is to be tied-up or supported at the constant velocity joint.

-

◆ Before removing, mark position of propshaft joint in relation to flange. Reinstall in the same positions otherwise the imbalance will be excessive; the bearings could be damaged and humming noises may occur.

-

◆ If complaints are received (noises, vibrations), it is essential to check whether correct adjustment of the propshaft rectifies the fault before replacing the propshaft.

-

◆ After removing the propshaft from the rear final drive, the additional balance disc (thicker washer) that may be located between the lock plate and the bolt head must not be reinstalled.

|