A4 Mk1

|

Servicing valve gear

Removing and installing camshaft

|

|

|

|

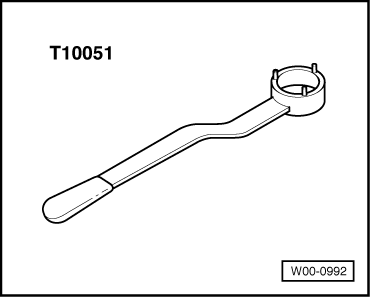

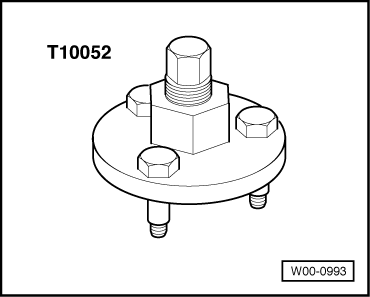

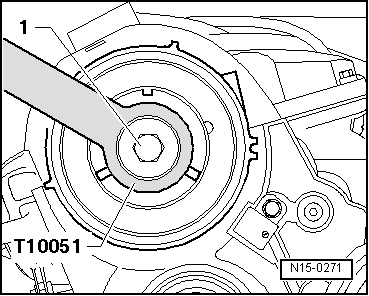

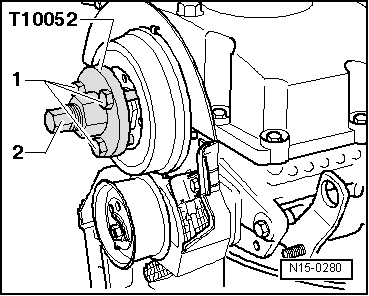

Special tools and workshop equipment required

|

|

|

|

|

|

|

Removing

|

|

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

Installing Install in reverse order, paying attention to the following:

|

|

|

|

Notes:

|

|

|

|

|

|

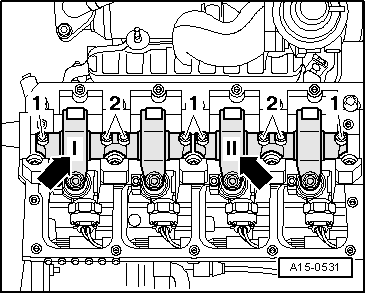

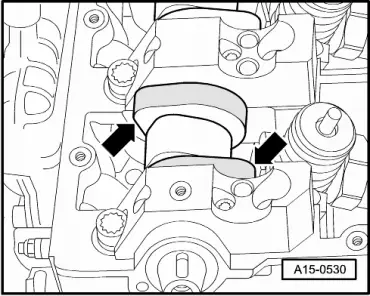

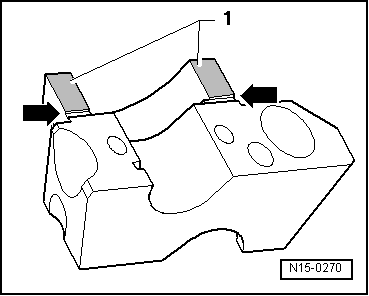

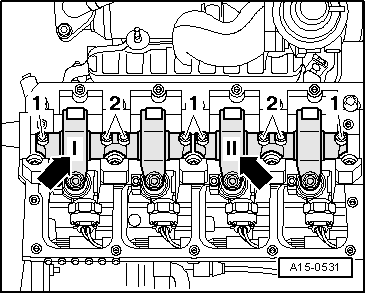

=> Parts List Note: Make sure no sealant gets into the grooves -arrows- or onto the other surfaces. |

|

|

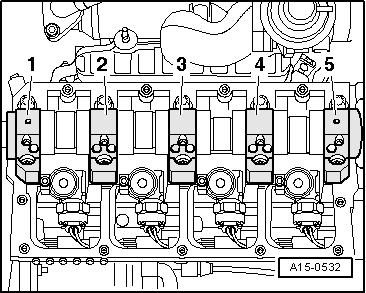

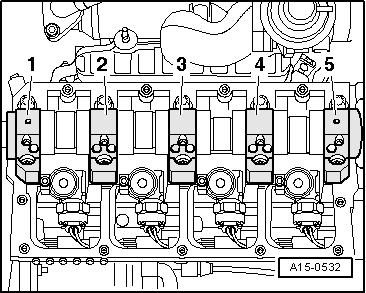

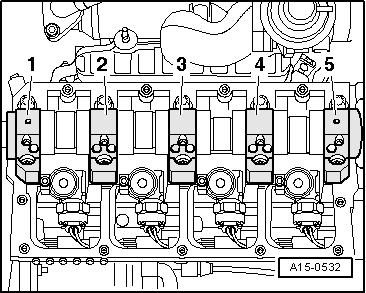

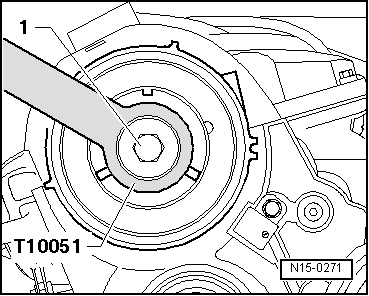

Note: Bearing cover 5 must abut flush with the outer edge of the cylinder head, otherwise the tandem pump may leak.

|

|

|

|

|

|

|

|||||||||||||

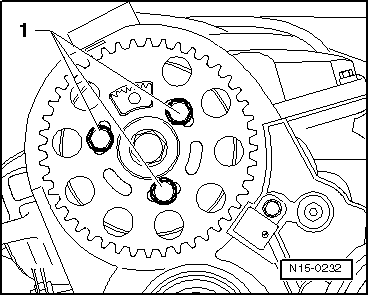

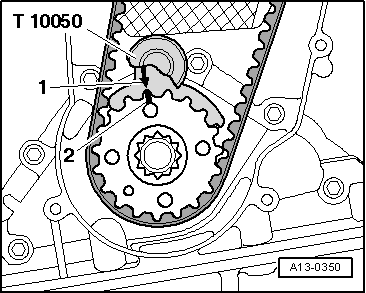

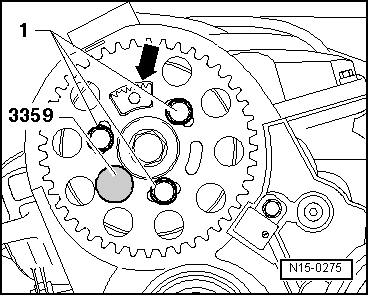

Note: The tooth segment -arrow- of the camshaft sprocket must be at the top.

=> Fuel supply - Diesel engines; Repair Group 20- Notes:

Tightening torques

1) 90°corresponds to quarter of a turn 2) Replace bolts |