-

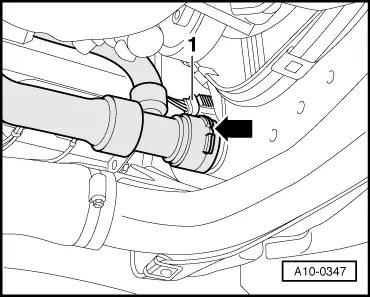

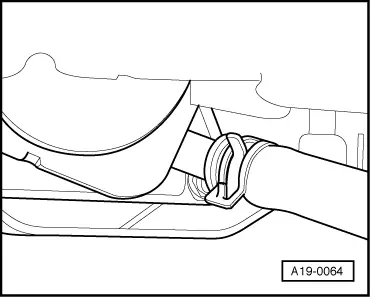

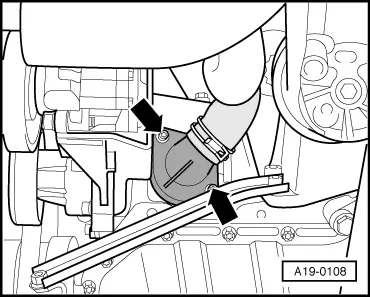

‒ → Remove bolts -arrows-, detach connection, O-ring and thermostat and drain remaining coolant.

Filling

Notes:

-

◆ The cooling system is filled all year round with a mixture of water and antifreeze/corrosion protection agent.

-

◆ Coolant additive G 011 A8 C (green) is used in vehicles up to 06.96.

-

◆ Only coolant additive G 012 A8 D (red) is used in vehicles from 07.96 onwards.

Important:

The two different coolant additives G 011 A8 C and G 012 A8 D must not be mixed together. Otherwise, this can result in serious damage to the engine.

-

◆ If the fluid in the expansion tank is brown, this means G 012 A8 D has been mixed with another type of coolant. In this case, flush out the cooling system and fill with fresh coolant. To flush the system, fill it with clean water and run the engine for about 2 minutes. This should remove as much of the old coolant as possible.

-

◆ G 011 A8 C and G 012 A8 D (and coolant additives marked "meeting specification TL VW 774 C" or "meeting specification TL VW 774 D") prevent frost and corrosion damage, stop scaling and at the same time raise the boiling point of the coolant. For these reasons the cooling system must be filled all year round with the correct anti freeze and anti corrosion additive.

-

◆ Because of its high boiling point, the coolant improves engine reliability under heavy loads, particularly in countries with tropical climates.

-

◆ Protection against frost must be assured to about -25 °C (in arctic climatic countries to about -35 °C).

-

◆ The coolant concentration must not be reduced by adding water even in warmer seasons and in warmer countries. The anti freeze ratio must be at least 40 %.

-

◆ If greater frost protection is required in very cold climates, the amount of G 012 A8 D can be increased, but only up to 60 % (this gives frost protection to about -40 °C), as otherwise frost protection is reduced again and cooling effectiveness is also reduced.

-

◆ If radiator, heat exchanger, cylinder head or cylinder head gasket is replaced, do not reuse old coolant.

|