A4 Mk1

|

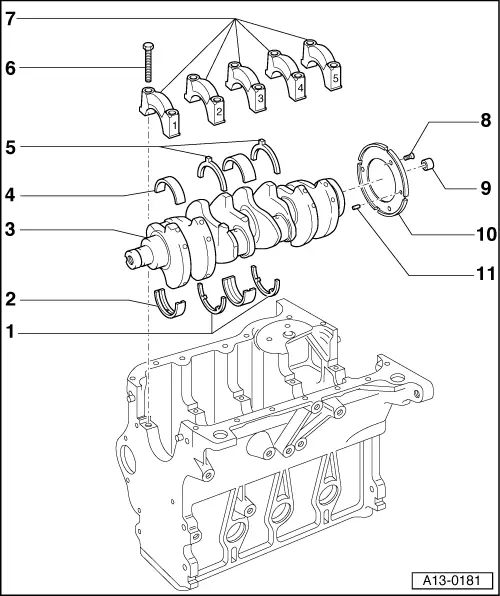

Removing and installing crankshaft

Removing and installing crankshaft

|

|

|

|

|

|

|

|

|

|

|

|

|

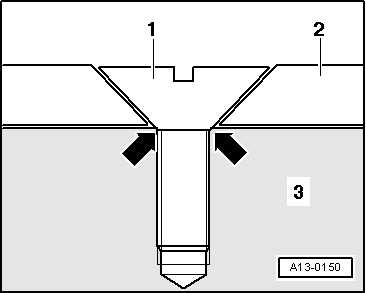

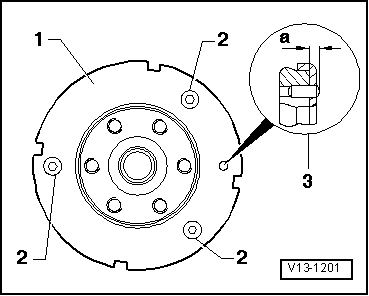

1) Renew bolts 2) 90°corresponds to a quarter turn → Fig.2 Checking projection of fitted pin from crankshaft Projection fitted pin -3- from crankshaft

|