| t

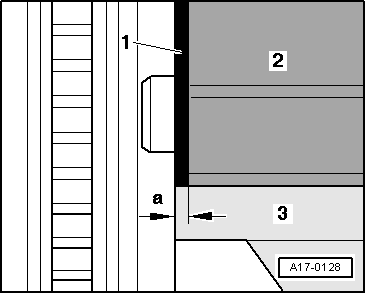

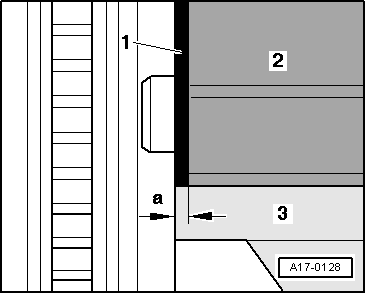

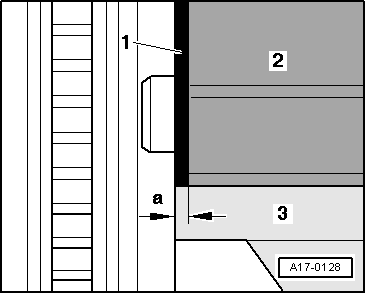

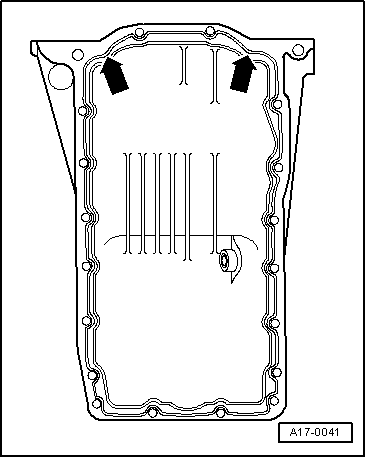

| When installing the sump -3- with the engine removed from the vehicle, make sure that it is positioned flush with the intermediate plate -1- at the flywheel end. In other words, the sump should protrude by 0.8 mm (distance -a-) from the cylinder block -2-. |

| t

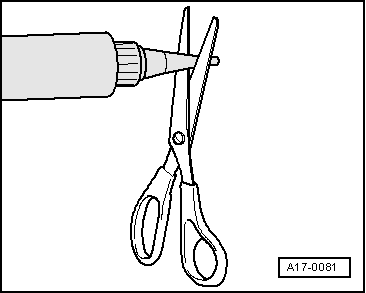

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| –

| Vehicles with automatic gearbox: secure ATF pipes → Rep. Gr.37. |

| –

| Vehicles with automatic gearbox: secure ATF pipes → Rep. Gr.37. |

| –

| Allow stop for torque reaction support to rest on rubber buffer for torque reaction support under its own weight, and tighten bolts. |

| –

| Vehicles with automatic gearbox: check ATF level → Rep. Gr.37. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note