A4 Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Component | Nm |

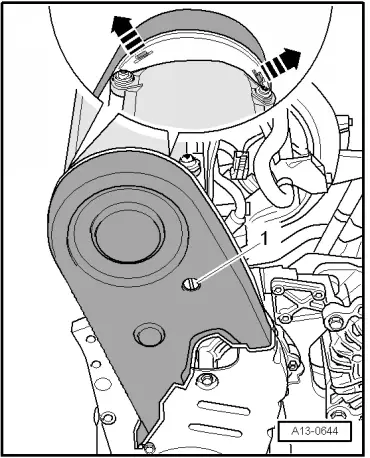

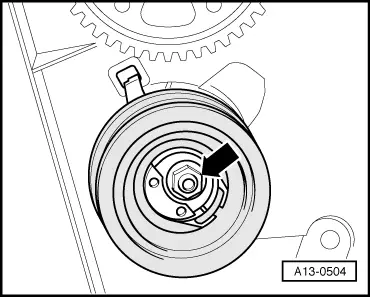

| Tensioning roller for toothed belt to cylinder head | 23 |

Caution

Caution