A4 Mk1

Note

Note

|

|

|

|

|

|

|

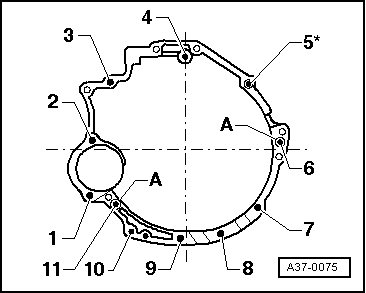

| Item | Bolt | Nm | ||

| 1, 3, 4 | M12x67 | 65 | ||

| 2, 6 | M12x90 | 65 | ||

| 5 *), 11 | M12x110 | 65 | ||

| 7 … 10 | M10x45 | 45 | ||

| A | Dowel sleeves for centralising | |||

| ||||

|

|

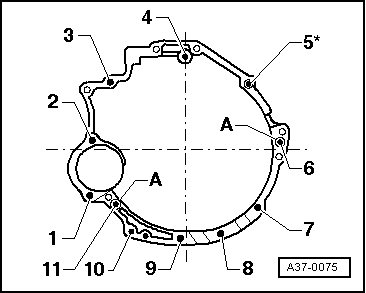

| Item | Bolt | Nm | ||

| 1, 8, 9, 10 | M10x45 | 45 | ||

| 2, 3, 4, 11 | M12x67 | 65 | ||

| 5 *) | M12x110 | 65 | ||

| 6 | M12×90 | 65 | ||

| 7 | M10x60 | 45 | ||

| A | Dowel sleeves for centralising | |||

| ||||

|

Note

Note

Note

Note

|

|

| Component | Nm | |

| Bolts/nuts | M6 | 10 |

| M7 | 15 | |

| M8 | 20 | |

| M10 | 45 | |

| M12 | 65 | |

| Except for the following: | ||

| Engine mounting to subframe | 25 | |

| Engine support to engine mounting | 25 | |

| Torque converter to drive plate | 85 | |

| Catalytic converter to turbocharger | 30 | |

| Bracket for ATF pipes | 10 | |

| Power steering pump to bracket | 23 | |

| Pulley to power steering pump | 23 | |

| Viscous fan to bearing | 45 | |

| A/C compressor to bracket | 25 | |

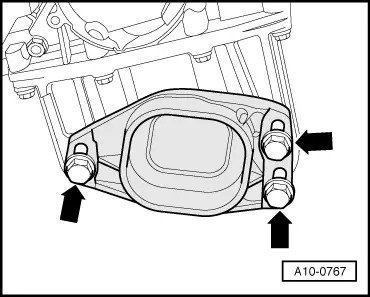

| Stop for torque reaction support to sump | 28 | |

| Hose clips for coolant hoses | 2 | |

| Hose clips for air hoses | 3.5 | |

Caution

Caution