A4 Mk1

| Renewing exhaust camshaft oil seal |

| Special tools and workshop equipment required |

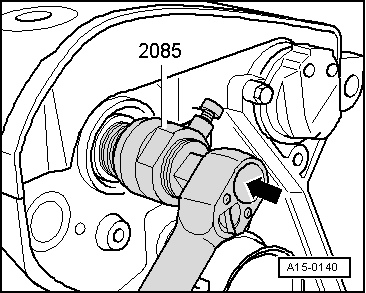

| t | Oil seal extractor -2085- |

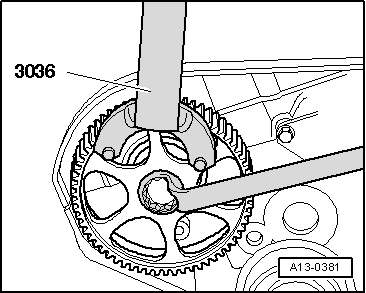

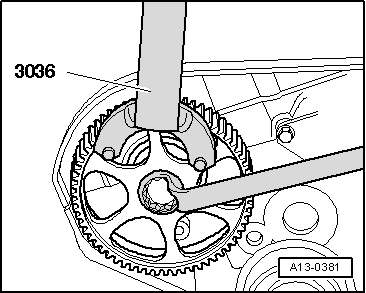

| t | Counterhold tool -3036- |

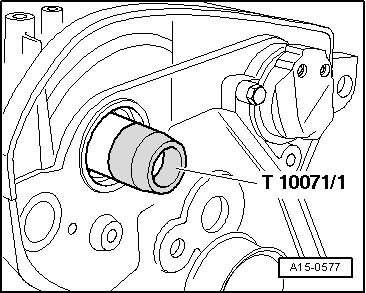

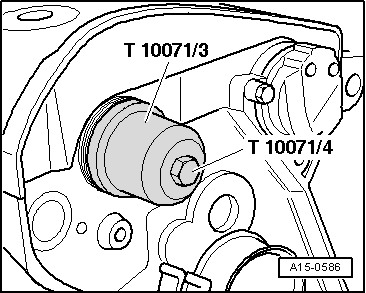

| t | Assembly tool -T10071- |

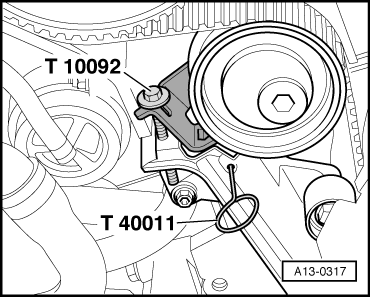

| t | Tensioning bolt -T10092- for vehicles up to 07.2000 |

| t | Locking pin -T40011- for vehicles up to 07.2000 |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

| Component | Nm |

| Camshaft sprocket to camshaft | 65 |

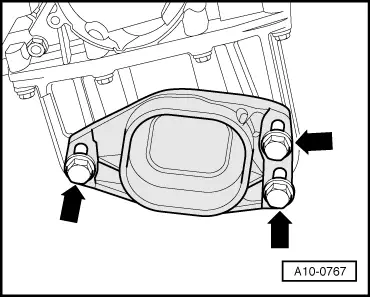

| Stop for torque reaction support to sump | 28 |

Caution

Caution