A4 Mk1

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | |||

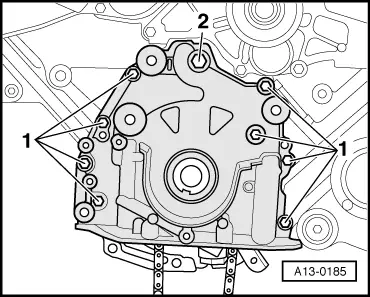

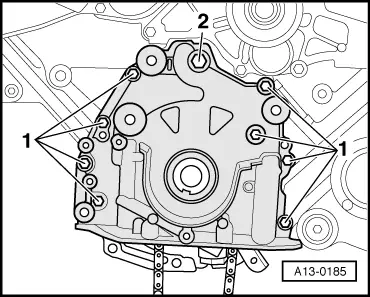

| Sealing flange (pulley end) to cylinder block | M6 | 10 | ||

| M8 | 30 | |||

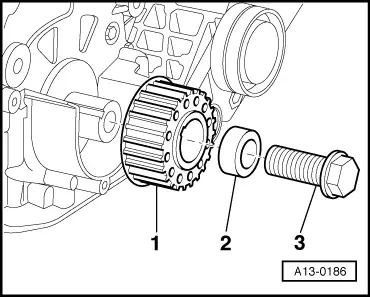

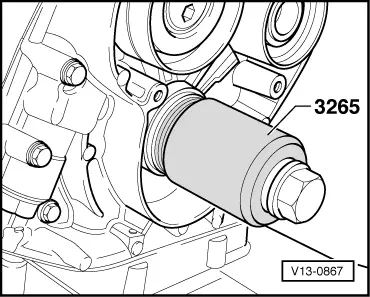

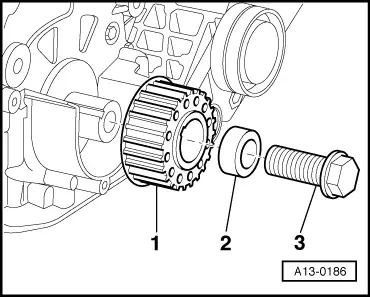

| Toothed belt sprocket to crankshaft | 200 + 180° 1) | |||

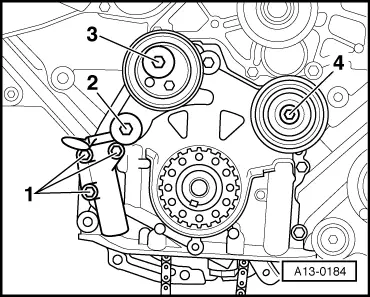

| Toothed belt tensioning roller to sealing flange (pulley end) | 42 | |||

| Tensioner to sealing flange (pulley end) | 10 | |||

| Tensioning lever to sealing flange (pulley end) | 42 | |||

| Idler roller to sealing flange (pulley end) | 45 | |||

| ||||