| –

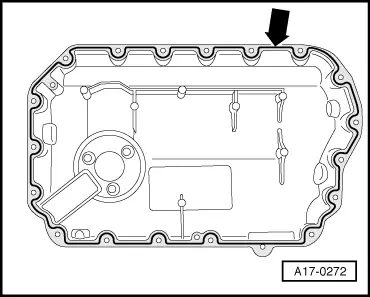

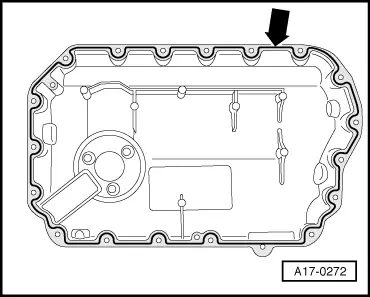

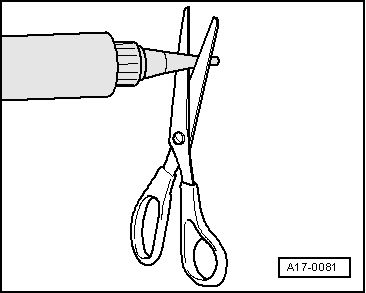

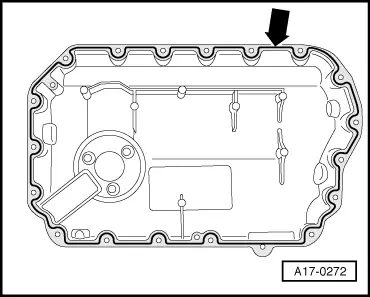

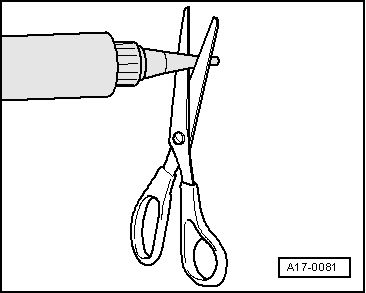

| Apply sealant bead to clean sealing surface of bottom section of sump, as shown in illustration. |

| l

| The bead of sealant should be approx. 1.5 mm wide -arrow-. |

Note | t

| The sump (bottom section) must be installed within 5 minutes after applying sealant. |

| t

| The sealant bead must not be thicker than specified, otherwise excess sealant could enter the sump and clog the strainer in the oil pump. |

| –

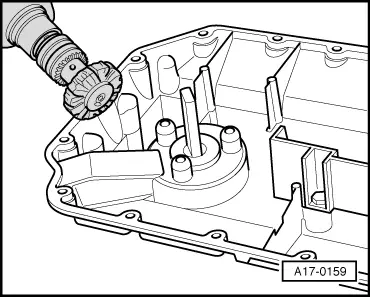

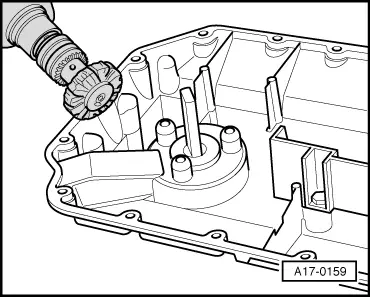

| Fit sump (bottom section) and tighten all bolts initially to 5 Nm in diagonal sequence. |

| –

| Tighten bolts on sump (bottom section) in diagonal sequence. |

| –

| Fill up with engine oil and check oil level → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note