A4 Mk1

|

Servicing Motronic fuel injection system

Testing fuel pressure, pressure regulator and holding pressure

Test requirements:

Note: Fuel pressure regulator regulates fuel pressure as a function of intake pressure. |

|

|

|

|

|

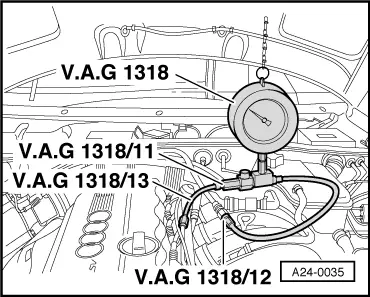

Note: The shut-off cock of the pressure measuring device must be open (lever facing in the direction of flow).

|

|

|

If the holding pressure drops below 2.5 bar:

If the holding pressure does not drop, the following faults are possible:

If the pressure drops again, the following faults are possible:

Note: To remove the pressure gauge, close the shut-off valve, unscrew the union on adapter V.A.G 1318/12, then open the shut-off valve to drain off excess fuel into a suitable container. |