A4 Mk1

|

Servicing diesel direct injection system

Removing and installing the injection pump Engine code: AHH

Remove the injection pump

=> General Body Assembly, Exterior; Repair group 50; Body front; Lock carrier-service position

|

|

|

|

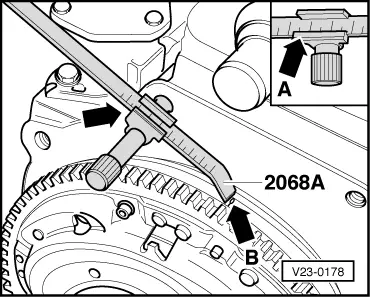

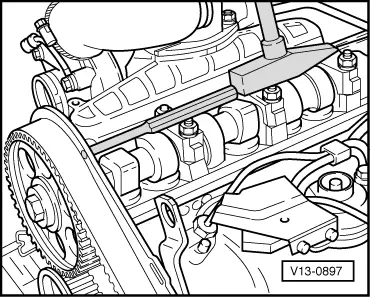

TDC-position of the crankshaft in vehicles with automatic gearboxes =>Page 23-39. TDC-position of the crankshaft in vehicles with manual gearboxes

With engine removed |

|

|

|

|

|

|

|

|

|

|

|

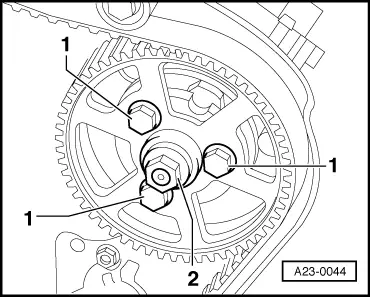

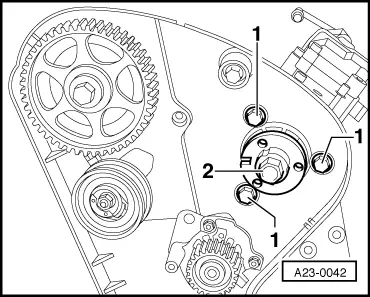

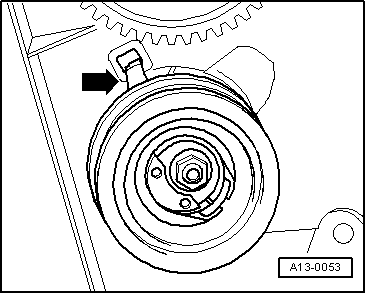

Note: Do not loosen hub nut -2-. Otherwise the injection pump basic setting is maladjusted and cannot be corrected using workshop tools. |

|

|

Installing the injection pump

|

|

|

|

|

|

|

|

|

|

|

|

|

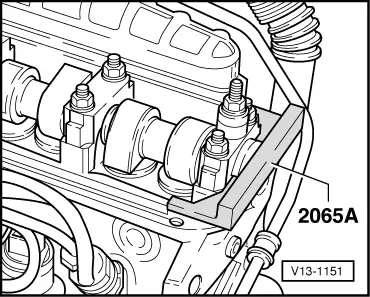

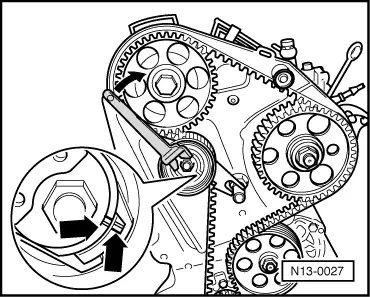

Note: → Make sure that the holding claw is correctly positioned.

Notes:

|

|

|

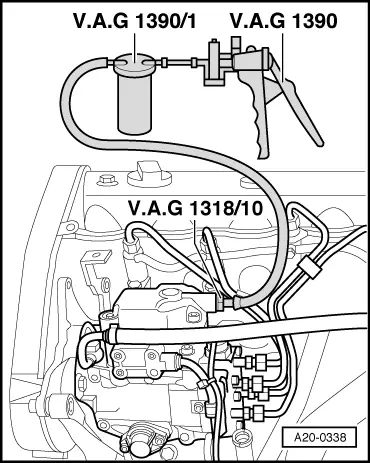

→ Fill injection pump with clean diesel fuel as follows:

|