A4 Mk1

|

|

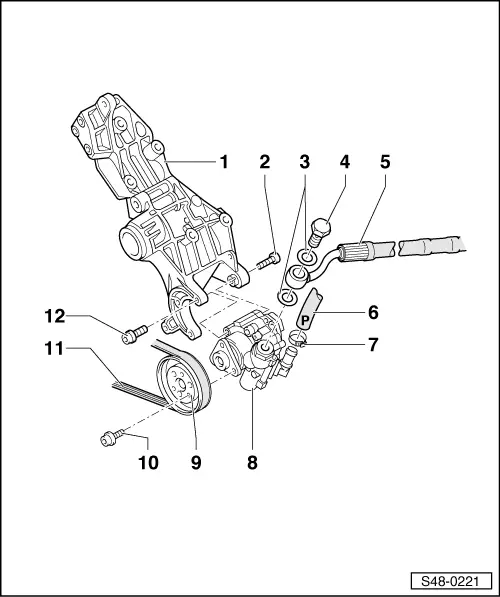

Removing

=> General Body Repairs, Exterior; Repair Group 63; Front Bumper

=> General Body Repairs, Exterior; Repair Group 50; Front Body

=> Engine, Mechanics; Repair Group 13; Dismantling and assembling engine This operation only applies to vehicles with 4-cyl. petrol engines |

|

|

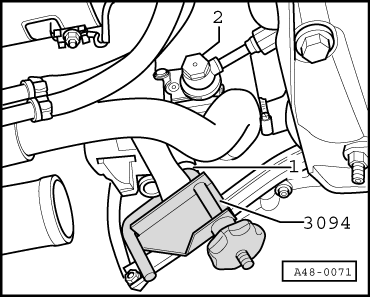

=> 4-cyl. Engine, Mechanics; Repair Group 19; Removing and installing cooling system components

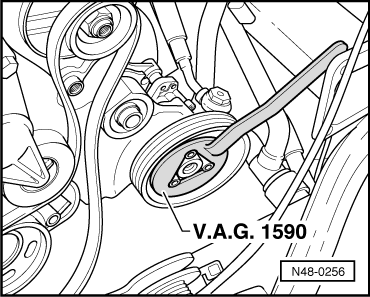

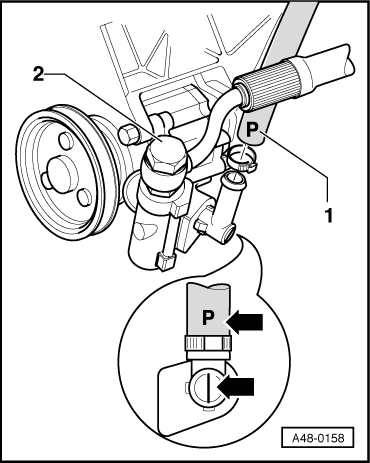

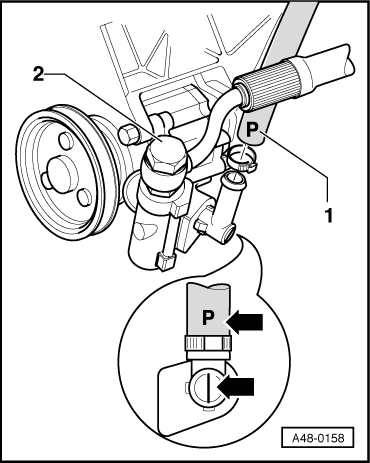

It may be necessary to file down corners of gripping wrench -V.A.G 1590-. |

|

|

|

All vehicles with 4-cyl. engines (continued)

|

|

|

|

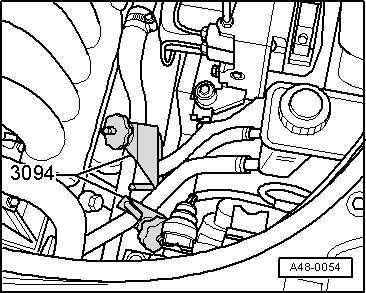

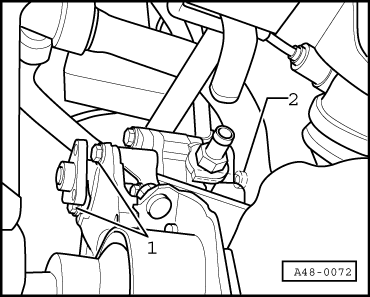

This operation only applies to vehicles up to MY '97

|

|

|

|

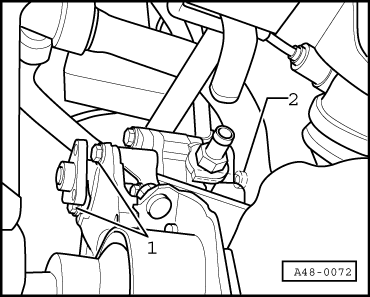

This operation only applies to vehicles as of MY '97 with new vane pump

|

|

|

|

All vehicles with 4-cyl. engines (continued)

Installing

|

|

|

|

|

|

|

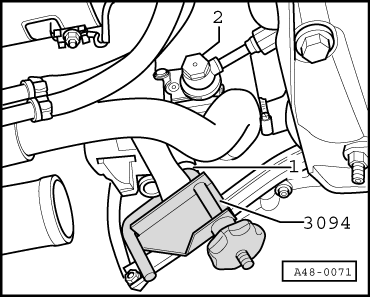

This operation only applies to vehicles up to MY '97

|

|

|

|

This operation only applies to vehicles as of MY '97 with new vane pump

All vehicles with 4-cyl. engines (continued)

|

|

|

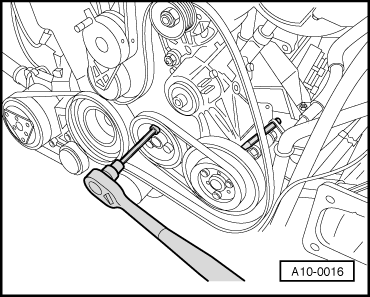

=> Engine, Mechanics; Repair Group 13; Dismantling and assembling engine When installing belt, make sure it is properly seated in pulleys.

=> General Body Repairs, Exterior; Repair Group 50; Front Body; Lock carrier service position

|