A4 Mk2

| Servicing cover for centre differential, removing and installing centre differential |

| Special tools and workshop equipment required |

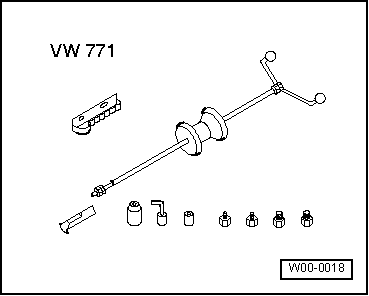

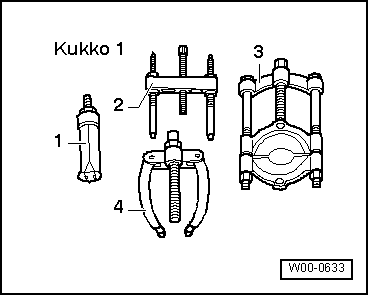

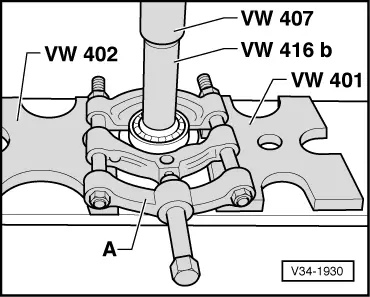

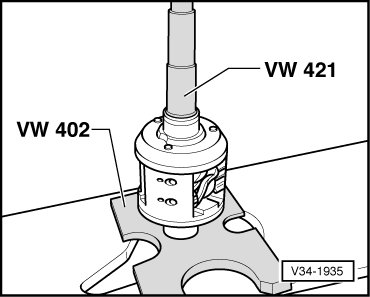

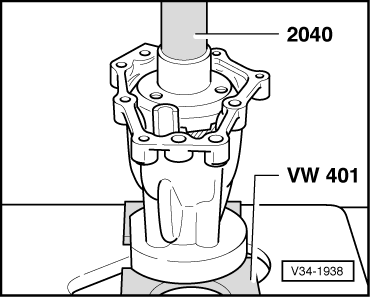

| t | Thrust plate -VW 401- |

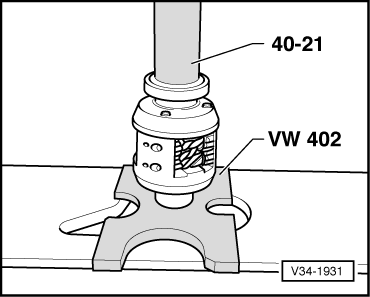

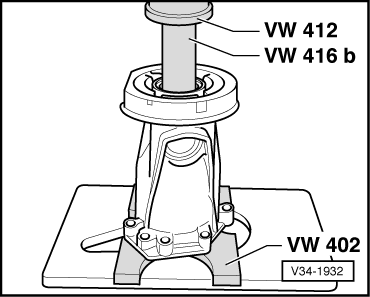

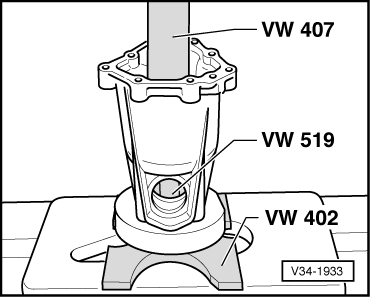

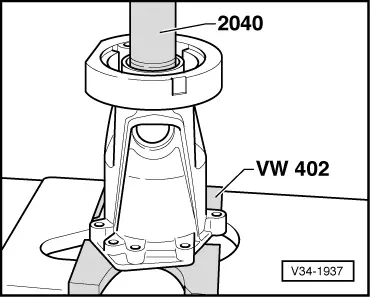

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 416 B- |

| t | Tube -VW 421- |

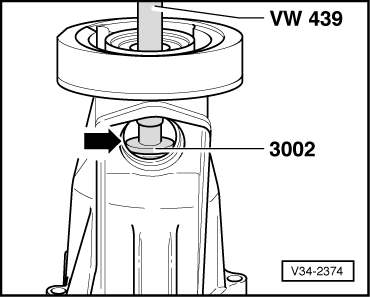

| t | Guide pin -VW 439- |

| t | Tube -VW 519- |

| t | Oil seal extractor lever -VW 681- |

| t | Press tool -40 - 21- |

| t | Tube -2040- |

| t | Thrust piece -3002- |

|

|

|

|

|

|

| 1 - | Gearbox cover |

| 2 - | Spring |

| 3 - | Front needle bearing |

| q | Pulling out → Fig. |

| q | Installation position → Fig. |

| q | Pressing in → Fig. |

| 4 - | Centre differential |

| q | Do not dismantle |

| q | Press out after removing flange shaft (rear) → Fig. |

| q | Renew if damaged |

| q | Pressing in → Fig. |

| 5 - | Rear needle bearing |

| q | Pulling out → Fig. |

| q | Installation position → Fig. |

| q | Pressing in → Fig. |

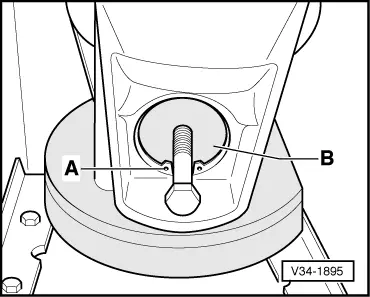

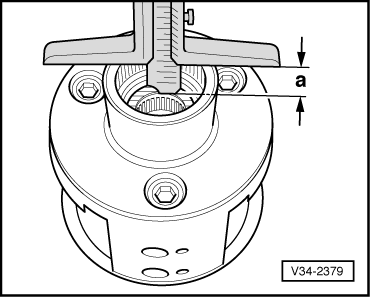

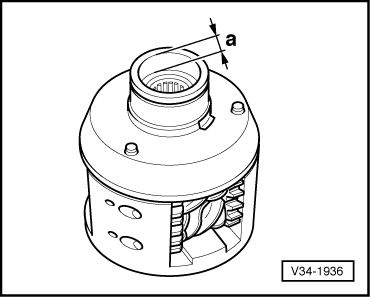

| 6 - | Ball bearing |

| q | For centre differential |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 7 - | Circlip |

| 8 - | Circlip |

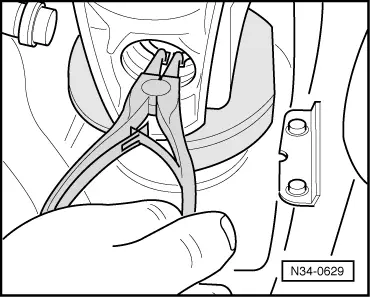

| q | Remove and install together with flange shaft → Fig. |

| 9 - | Ball bearing |

| q | For flange shaft (rear) |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 10 - | Cover |

| q | For centre differential |

| 11 - | Circlip |

| 12 - | Sealing cap |

| q | Removing → Fig. |

| 13 - | O-ring |

| q | Always renew |

| q | Grease when installing |

| 14 - | TORX bolt |

| q | 22 Nm |

| 15 - | Oil seal |

| q | Pull out with oil seal extractor lever -VW 681- |

| q | Driving in → Fig. |

| 16 - | Damper weight |

| 17 - | Circlip |

| 18 - | TORX bolt |

| q | 35 Nm |

| q | Self-locking |

| q | Always renew |

| 19 - | Flange shaft (rear) |

| q | Removing and installing → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|