| –

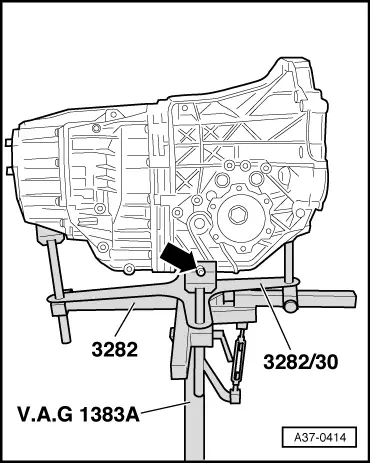

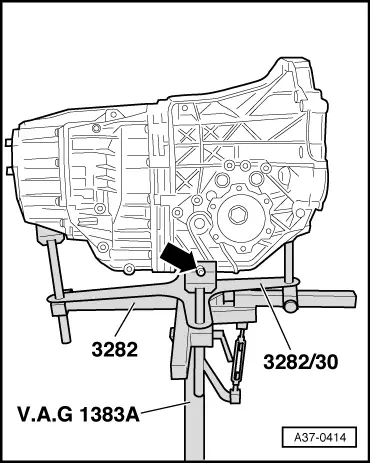

| Raise gearbox carefully and move to installation position using gearbox support -3282-. |

| –

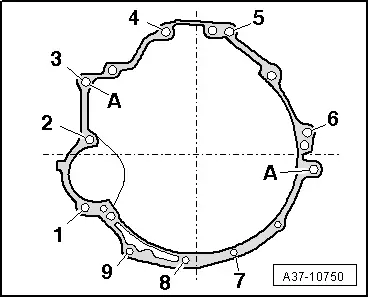

| Bolt gearbox onto engine with new bolts. |

| –

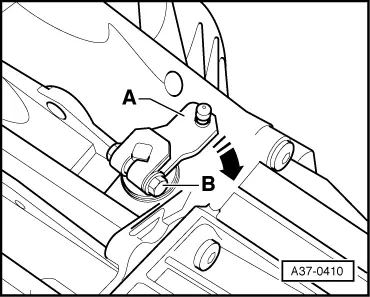

| Raise gearbox slightly at rear to install lower bolts for securing gearbox to engine. |

| The remaining installation steps are carried out in reverse sequence; note the following: |

Caution | There is a risk of damage to the gearbox due to inadequate ATF cooling. |

| All plugs inserted in ATF pipes and gearbox when dismantling must be removed. |

|

| –

| Install ATF pipes with new O-rings → Chapter. |

| –

| Follow the steps required after connecting the battery → Rep. Gr.27. |

| –

| Check selector lever cable adjustment → Chapter. |

| –

| Check gear oil level in front final drive → Chapter. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gearbox oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques ±15%. |

|

|

|

Note

Note Note

Note

Note

Note

Caution

Caution