A4 Mk2

| Servicing gearbox cover |

| Special tools and workshop equipment required |

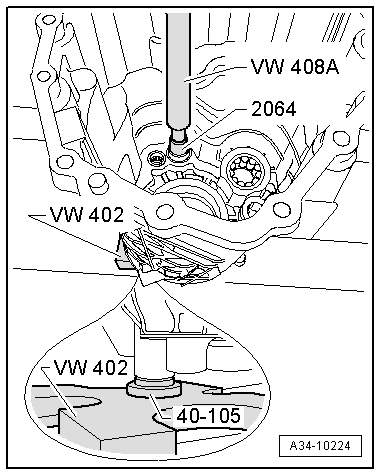

| t | Thrust plate -VW 401- |

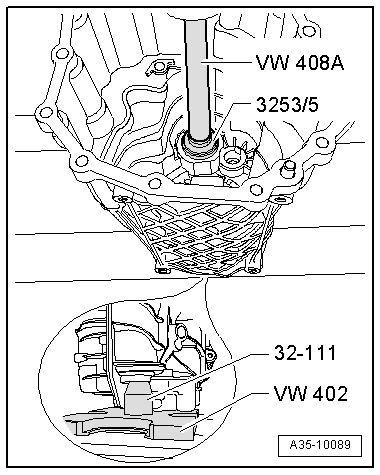

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

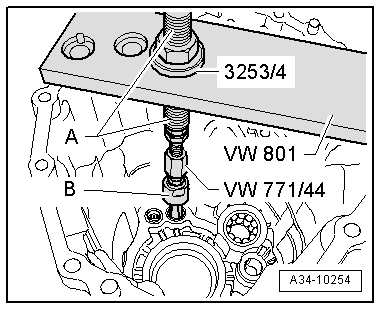

| t | Multi-purpose tool -VW 771- |

| t | Adapter -VW 771/44- |

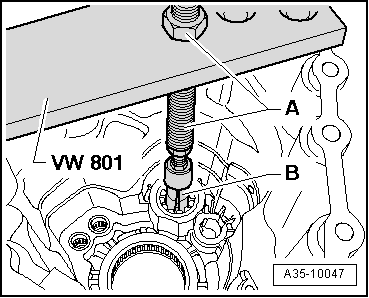

| t | Support plate -VW 801- |

| t | Thrust piece -32 - 111- |

| t | Thrust plate -40 - 105- |

| t | Locking pin -2064- |

| t | Assembly tool -3253- |

| t | -1-Internal puller -Kukko 21/2- |

| t | -1-Internal puller -Kukko 21/4- |

| t | -4-Counter-support -Kukko 22/2- |

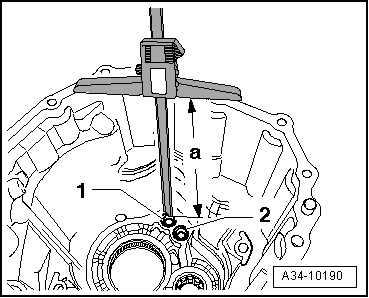

| t | Depth gauge |

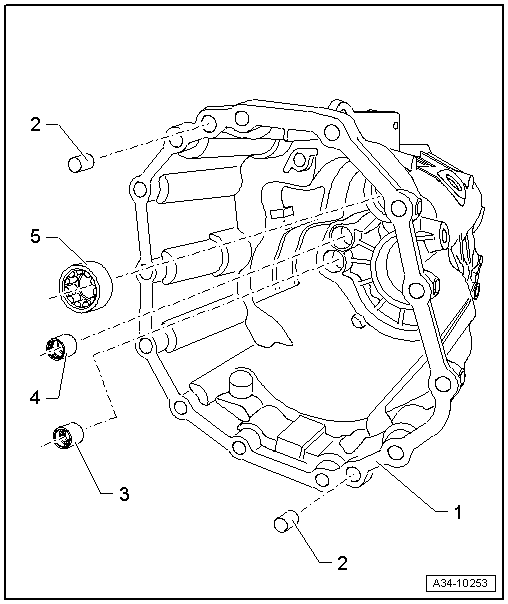

| 1 - | Gearbox cover |

| 2 - | Dowel pin |

| q | 2 x |

| q | Insert in gearbox cover |

| q | Drive in until flush with rear surface of housing flange |

| 3 - | Ball sleeve |

| q | For reverse gear selector rod |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

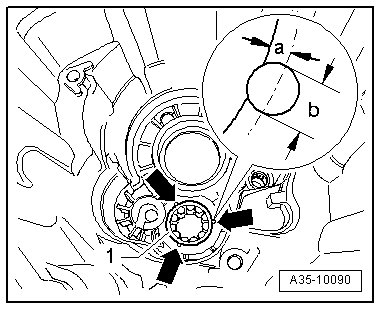

| q | Measuring installation depth → Fig. |

| 4 - | Ball sleeve |

| q | For selector rod for 1st and 2nd gear |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Measuring installation depth → Fig. |

| 5 - | Roller bearing |

| q | Bearing for input shaft in gearbox cover |

| q | Always renew |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Peen to secure after installing → Fig. |

|

|

|

|

Note

Note

|

|

|

|

|

|