A4 Mk2

Note

Note

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

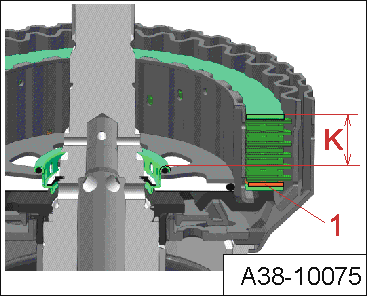

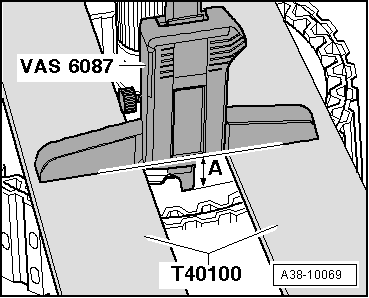

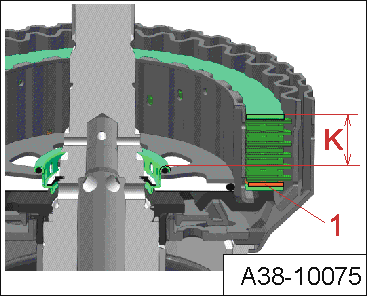

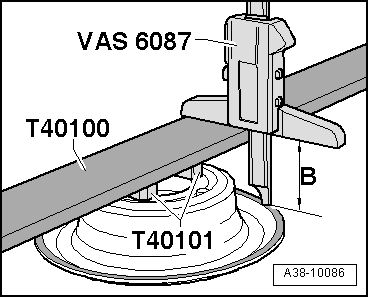

| Mean value of pressure plate measurements “M D” (value 1 + value 2 + value 3) : 3 | |

| – | Mean value of clutch measurements “MK” (value 1 + value 2 + value 3 + value 4) : 4 |

| = | Clearance |

|

| Available shims [thickness in mm] | ||

| 1,90 | 2,15 | 2,65 |

| 2,90 | 3,15 | |

Note

Note

|

|

|

Caution

Caution