A4 Mk2

| Removing engine |

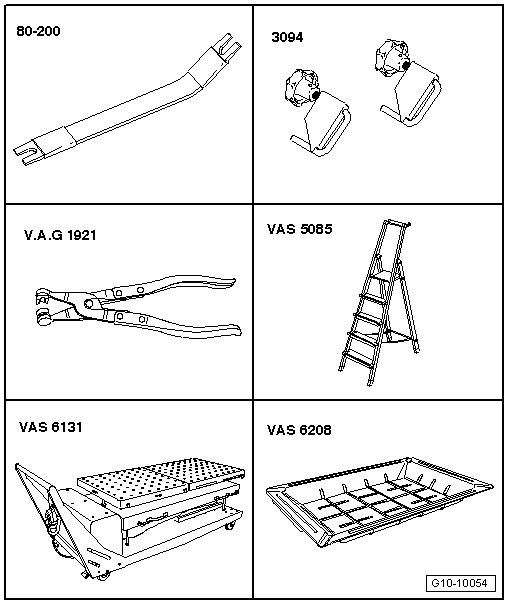

| Special tools and workshop equipment required |

| t | Removal lever -80-200- |

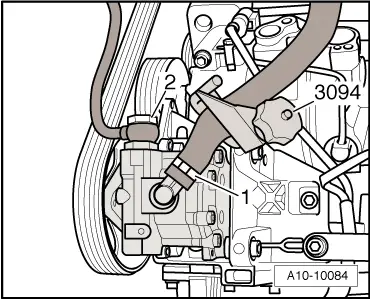

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Stepladder -VAS 5085- |

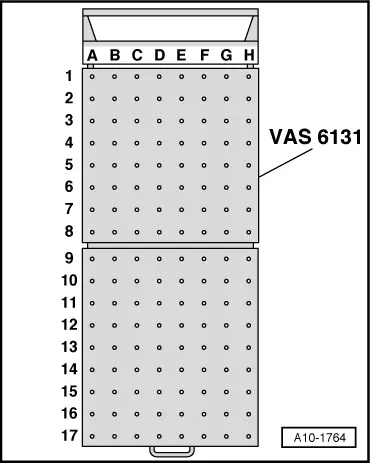

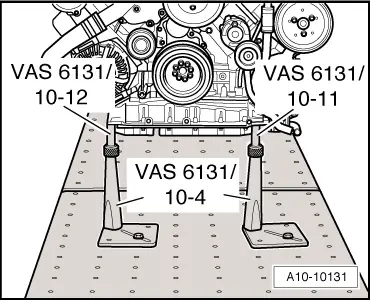

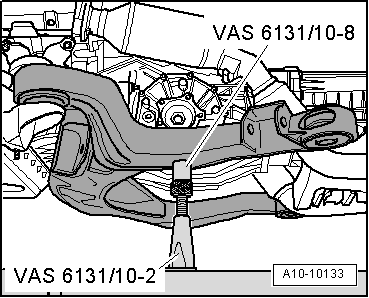

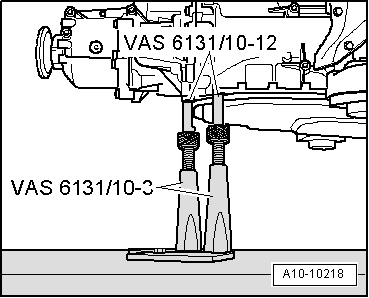

| t | Scissor-type assembly platform -VAS 6131 A- with support set for Audi -VAS 6131/10- and adapter -VAS 6131/10-12- |

| t | Drip tray for workshop hoist -VAS 6208- |

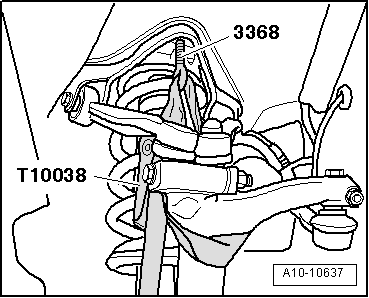

| t | Eye-head bolt -3368- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Tensioning strap -T10038- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

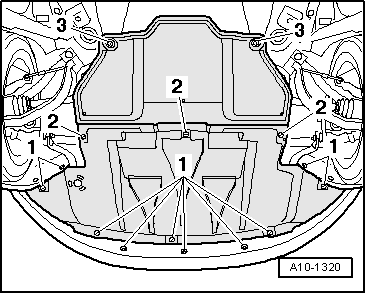

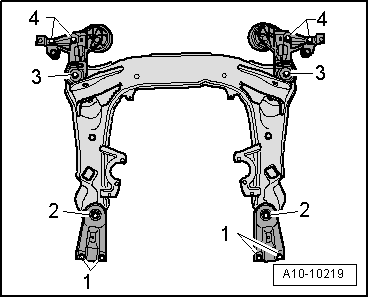

| Platform coordinates | Parts of support set for Audi -VAS 6131/10- | |||

| B4 | /10-1 | /10-4 | /10-5 | /10-11 |

| G4 | /10-1 | /10-4 | /10-5 | /10-12 |

| B11 | /10-1 | /10-2 | /10-5 | /10-8 |

| G11 | /10-1 | /10-2 | /10-5 | /10-8 |

| D15 | /10-1 | /10-3 | /10-5 | /10-12 |

| F15 | /10-1 | /10-3 | /10-5 | /10-12 |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

Caution

Caution WARNING

WARNING