A4 Mk2

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

| Stage | Tightening | ||

| I |

| ||

| II |

| ||

| III |

|

|

|

|

|

|

|

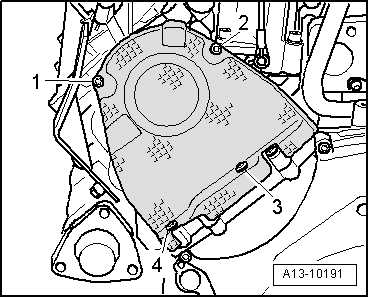

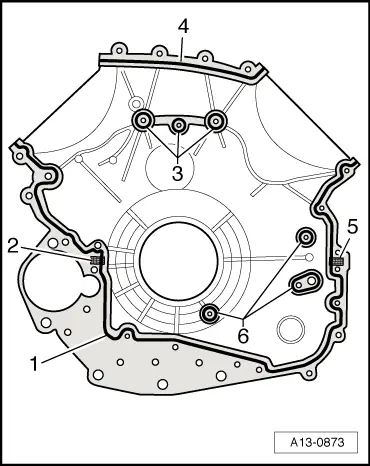

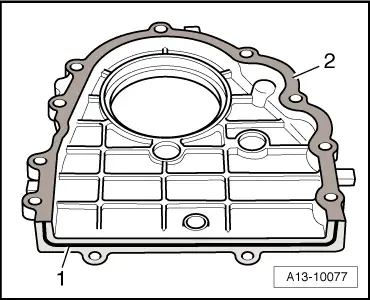

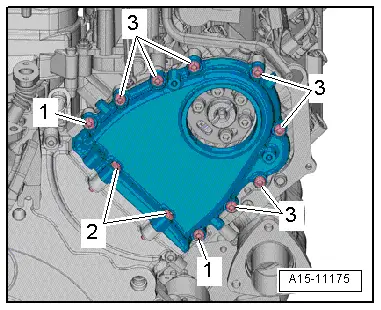

| Stage | Bolts | Tightening torque |

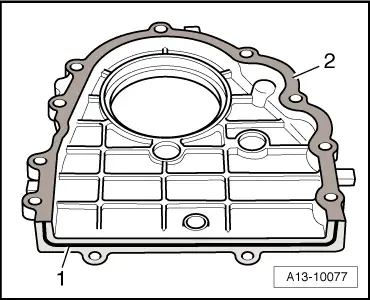

| 1. | -1- | 3 Nm |

| 2. | -2- | 9 Nm |

| 3. | -1- | 9 Nm |

| 4. | -3- | 9 Nm in diagonal sequence |

|

|

|

|

|

|

|

|

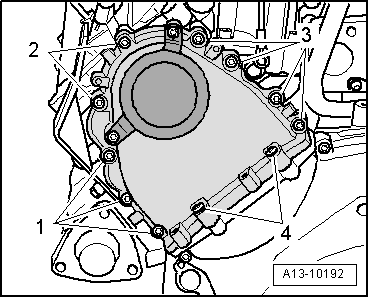

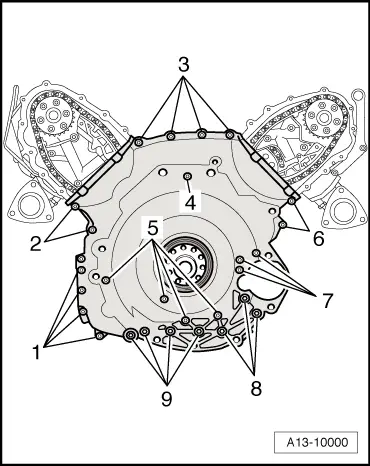

| Stage | Bolts | Tightening torque |

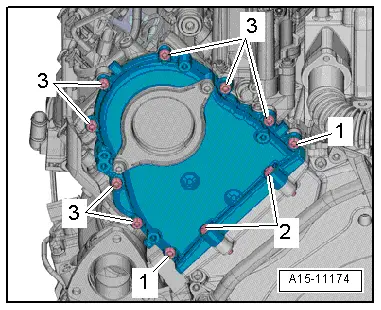

| 1. | -1- | 3 Nm |

| 2. | -2- | 9 Nm |

| 3. | -1- | 9 Nm |

| 4. | -3- | 9 Nm in diagonal sequence |

|

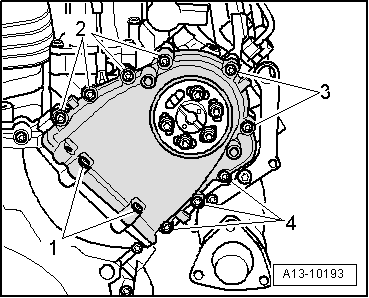

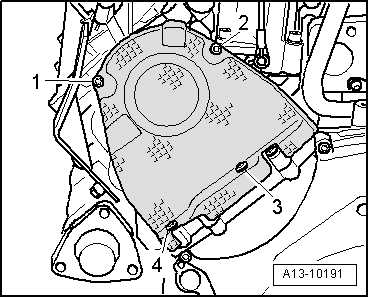

| Component | Nm | |

| Timing chain cover (bottom) to engine | M6 | 9 |

| M8 | 23 | |

WARNING

WARNING Caution

Caution