A4 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

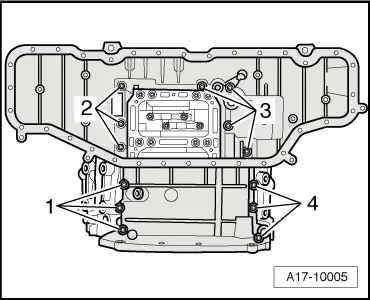

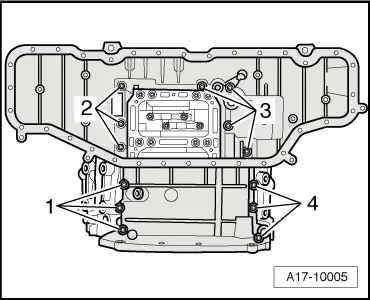

| Component | Nm | |

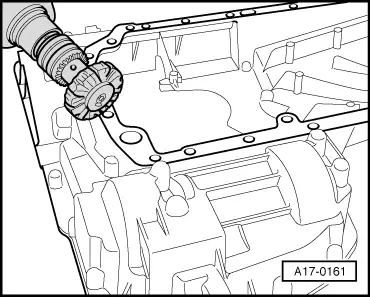

| Sump (top section) to cylinder block | 15 | |

| Coolant pipe to: | Sump (top section) | 9 |

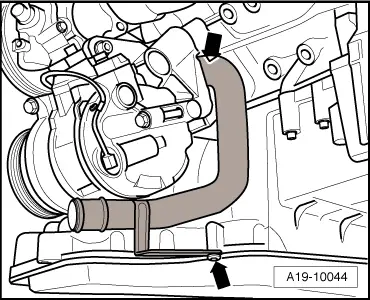

| Bracket for air conditioner compressor | 9 | |

WARNING

WARNING