| –

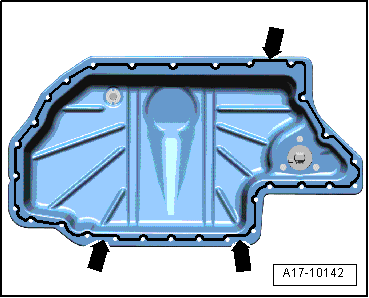

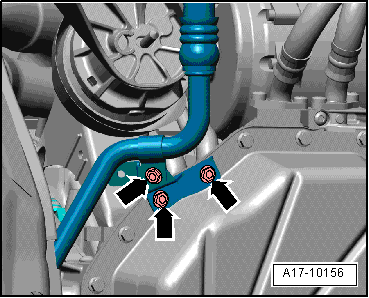

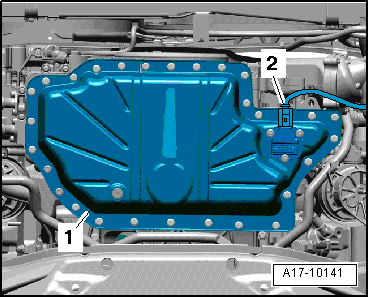

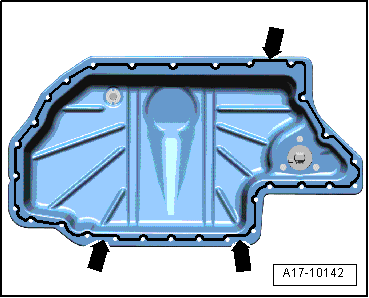

| Apply bead of sealant -arrows- onto clean sealing surface of sump (bottom section) as illustrated. |

| l

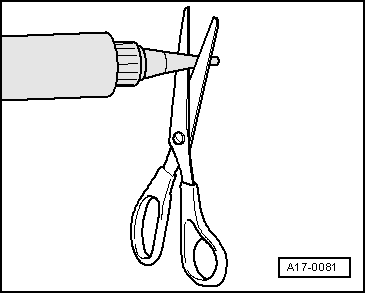

| Width of sealant bead: 2.5 mm. |

Note | t

| Note the position of sealant at the points marked with -arrows-. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump (bottom section) and obstruct the strainer in the oil intake pipe. |

| t

| The sump (bottom section) must be installed within 5 minutes after applying sealant. |

| –

| Fit sump (bottom section) and tighten all bolts hand-tight. |

| –

| Tighten bolts for sump (bottom section) in two stages as follows. |

| 1.

| Tighten all bolts to an initial torque of 5 Nm in diagonal sequence. |

| 2.

| Tighten all bolts to 9 Nm in diagonal sequence. |

| Remaining installation steps are carried out in reverse sequence; note the following: |

|

|

|

Note

Note

Note

Note

WARNING

WARNING