A4 Mk2

|

Servicing injection system

Removing and installing injectors, replacing combustion-chamber sealing ring (Teflon sealing ring)

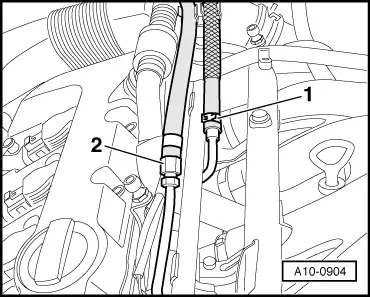

Always follow pressure dissipation procedure, Page 24-4. Note: Use the exploded views on the previous pages. The combustion-chamber sealing ring (Teflon) and the O-ring must always be replaced. The injectors can only be accessed after removal of the intake manifold and fuel rail with load motion flap for air flow control. (Additional or fewer steps may be required depending on the version.) Observe the illustrations on the previous pages as they also give the tightening torques. |

|

|

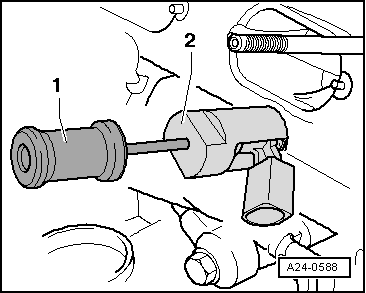

Removing injectors Injectors may remain lodged in cylinder head. Special tools have been designed for this eventuality. Their use is described below. Note:

|

|

|

|

|

|

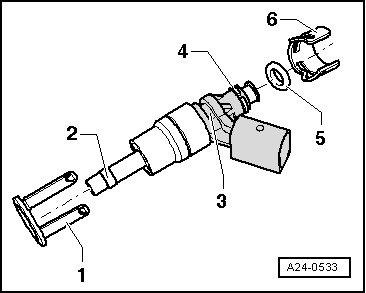

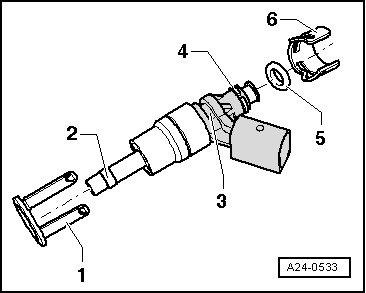

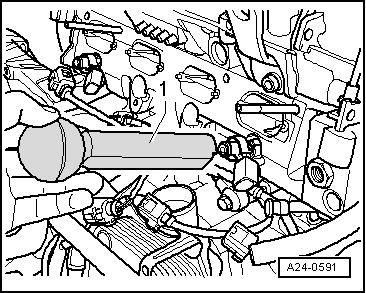

Note: When the injector is fitted, the radial compensation element (Item 1 in illustration above, previous page) is clipped into the support ring (Item 6). To remove the injector, the support ring must be removed from the injector so that the extractor T10133/2 can be inserted into the chamfer on the injector (Item 3, previous illustration). |

|

|

|

|

|

Replacing combustion-chamber sealing ring (Teflon sealing ring) |

|

|

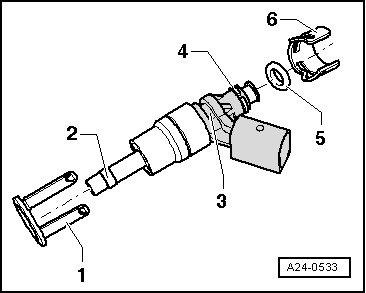

The combustion-chamber sealing ring must always be replaced prior to reinstalling the high-pressure injector.

Note: The injector must be replaced if the groove is damaged.

Note: |

|

|

|

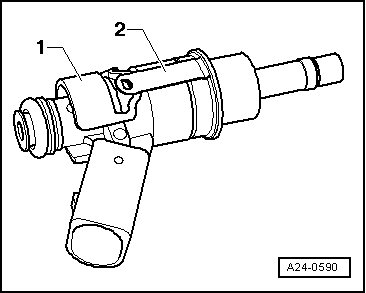

The illustration shows an injector with "offset connector". This can be ignored since it is not relevant when replacing the combustion-chamber sealing ring.

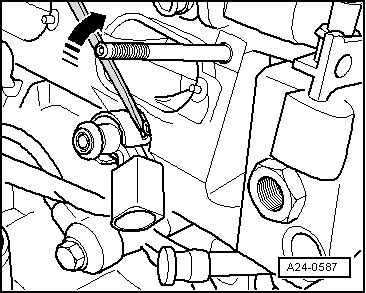

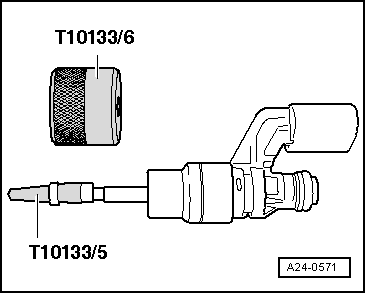

Note: The Teflon ring is widened when it is pushed onto the injector. The Teflon ring must therefore be narrowed again after it has been fitted. This is done in two steps. The procedure is described below. Step 1 of Teflon ring calibration (adaption) involves special tool T 10133/7. |

|

|

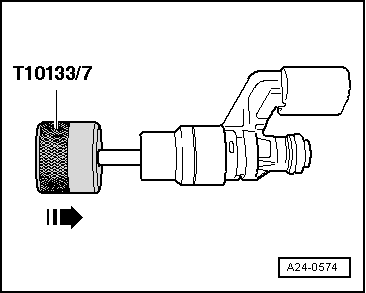

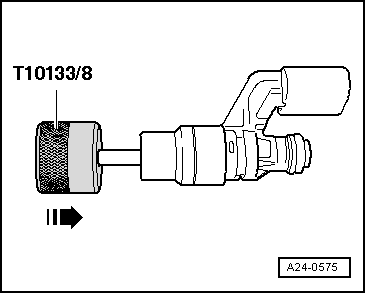

Step 2 of Teflon ring calibration (adaption) involves special tool T 10133/8. |

|

|

|

|

|

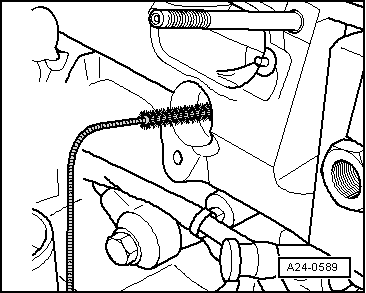

Note: An open inlet valve may prevent cleaning. If so, the engine must be cranked by hand by rotating the crankshaft with a spanner. |

|

|

|

|

|

Install in reverse order Important: The following points must always be observed:

|