| t

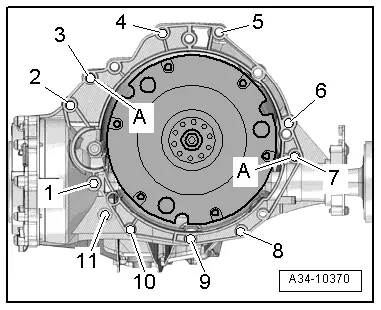

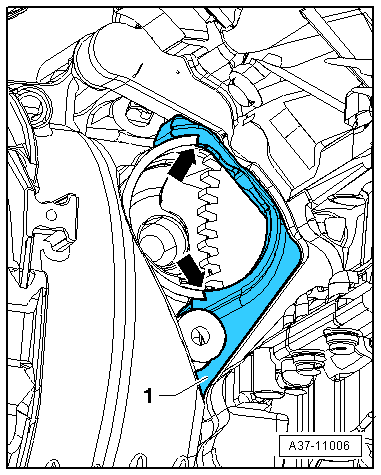

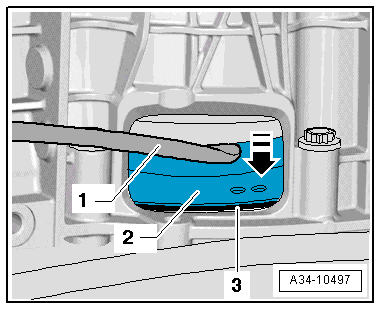

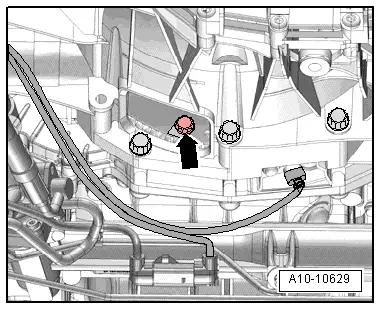

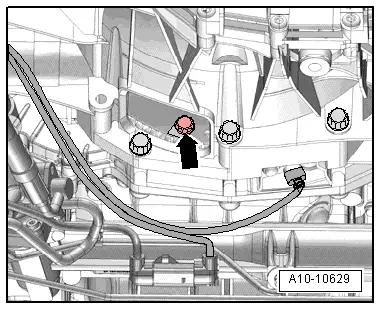

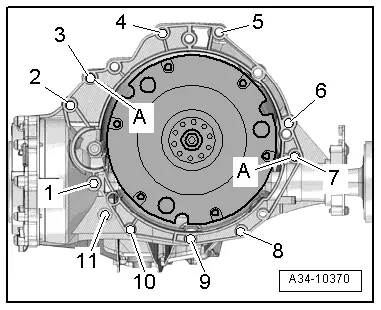

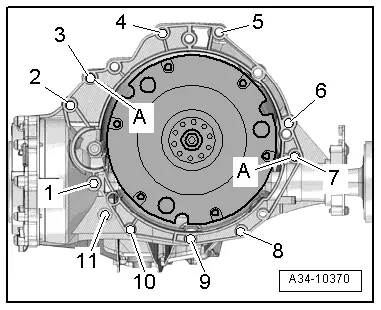

| Audi A4 from vehicle identification no. 8K-9A-066500 onwards, Audi A5 from vehicle identification no. 8T-9A-008000 onwards: aluminium bolts -2 ... 11- can be used twice only. After they have been used once, an “X”-arrow- must therefore be chiselled onto the bolts. |

| t

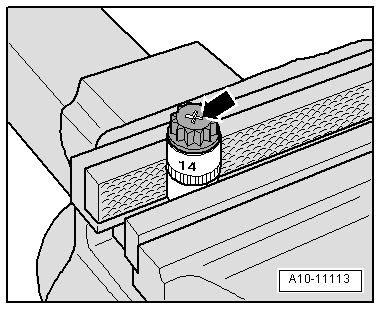

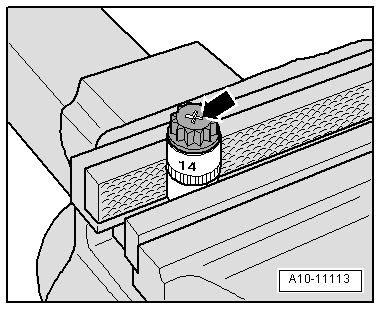

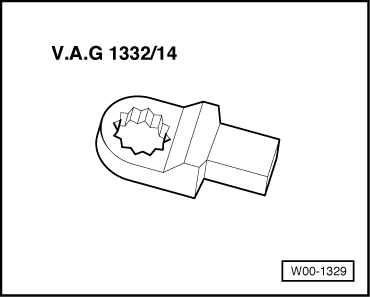

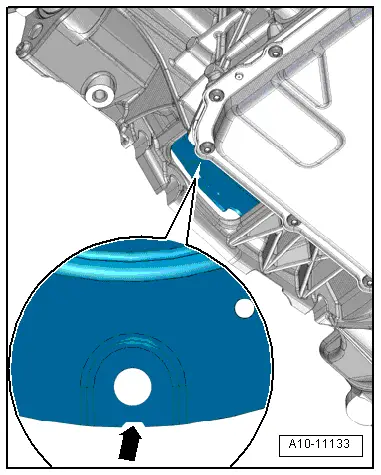

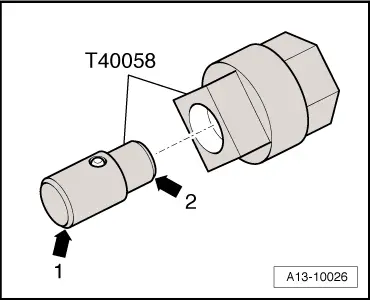

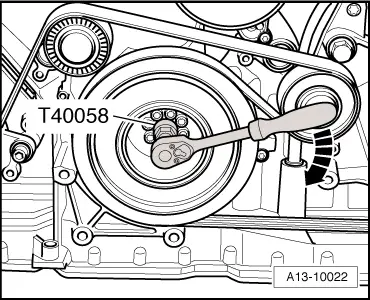

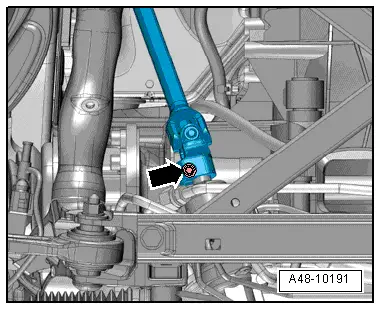

| To prevent damage to the bolts, they must not be clamped in a vice when marking them. Clamp a 14 mm socket with 1/2” drive in the vice instead, and insert the bolt into the socket, as shown in illustration. |

| t

| Bolts marked with an “X” must not be used again. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution