| l

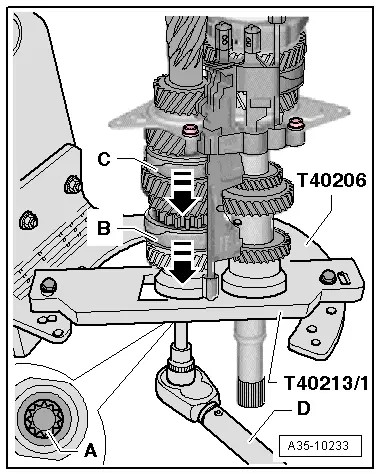

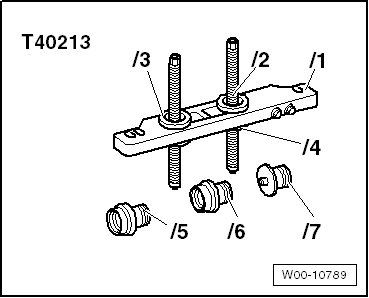

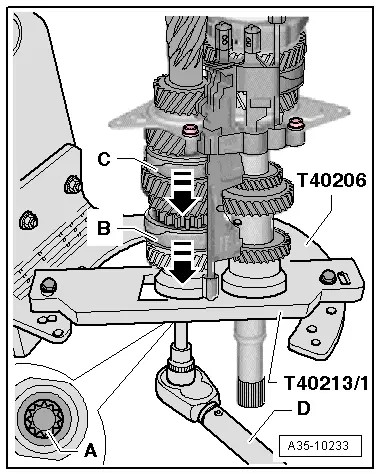

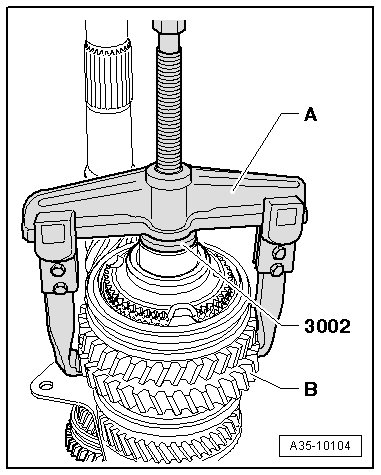

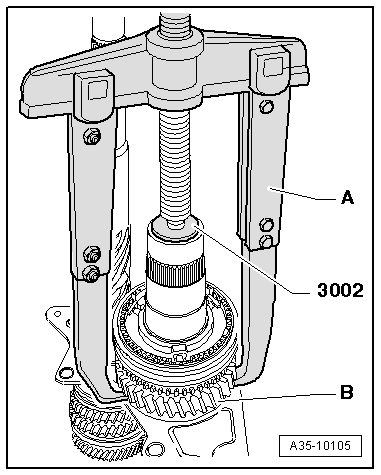

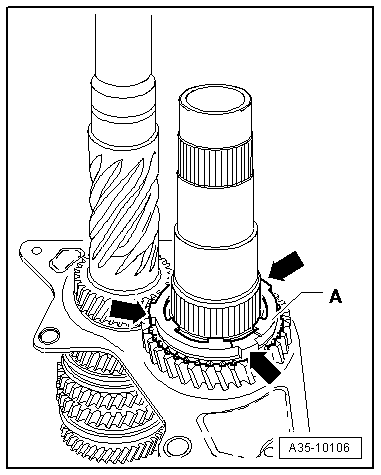

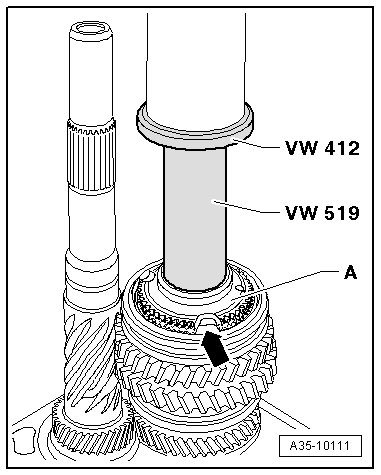

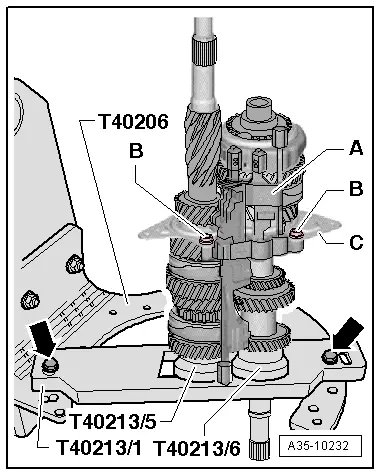

| If you have dismantled and assembled the input shaft, now tighten bolt -A- in the input shaft to the specified torque using torque wrench -D- or similar → Item. Before installing the bolt, clean the thread with a wire brush and then apply locking fluid -AMV 185 101 A1-. |

| l

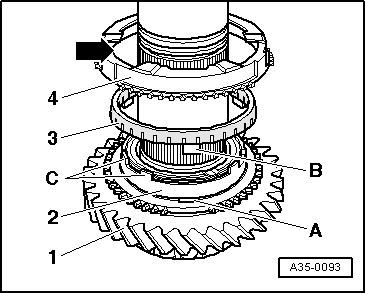

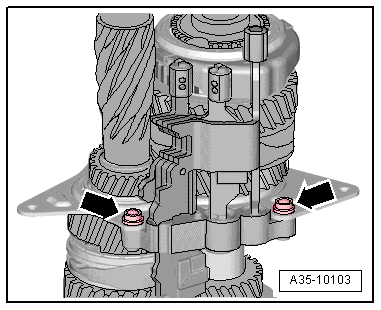

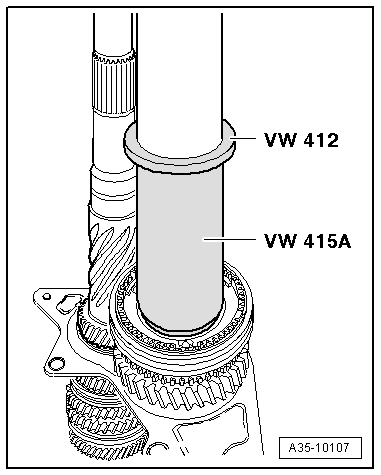

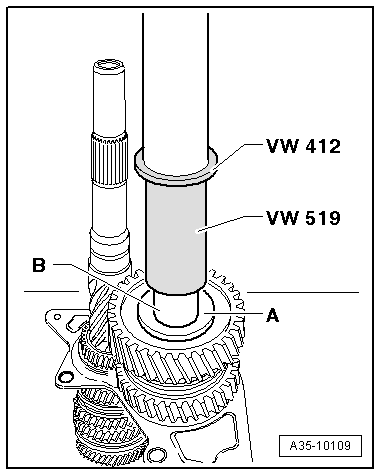

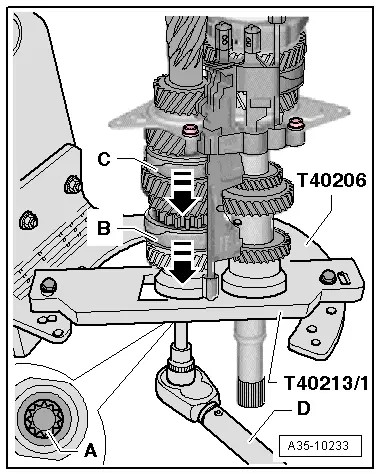

| To tighten the bolt, engage 2 gears by moving locking collars -B- and -C- in direction of -arrow-. |

| l

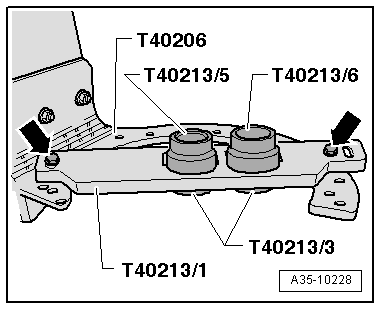

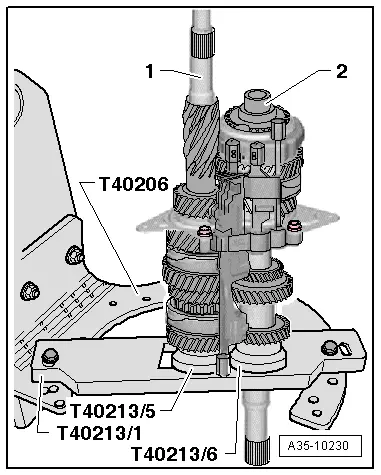

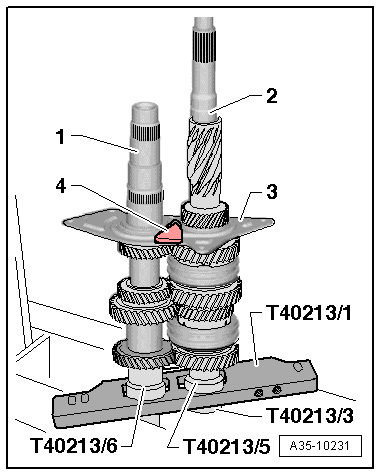

| The shafts must be vertical, as shown in illustration. |

| –

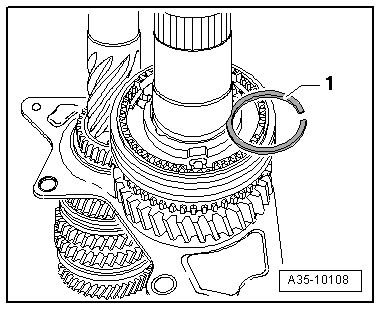

| Then move locking collars back to neutral position. |

Note | In order to move the locking collars -B- and -C- back into the centre position, turn the input shaft slightly anti-clockwise via bolt -A-. |

| –

| Remove input shaft together with output shaft and selector fork cluster from plate -T40213/1-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution